Treatment method for heavy-metal-polluted industrial wastewater by combining chemical leaching and biological reactions

A technology for chemical leaching and industrial wastewater, applied in biological water/sewage treatment, chemical instruments and methods, neutralized water/sewage treatment, etc., can solve the problems of unstable treatment effect, high cost, complicated technology, etc., and achieve design The effect of low construction cost, low replacement cost and simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

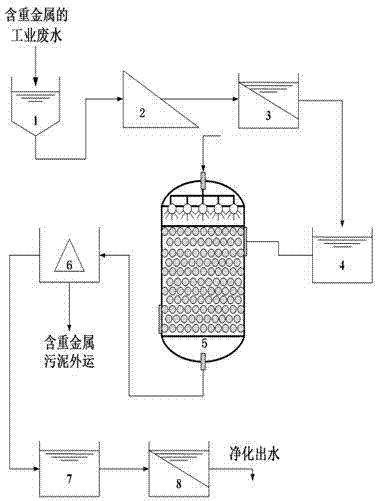

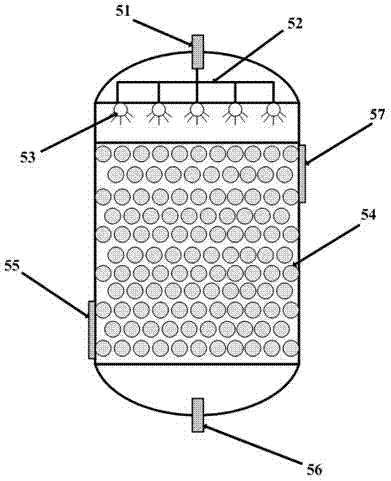

[0030] Such as figure 1 As shown in the treatment method for removing heavy metals in industrial waste water, industrial waste water containing heavy metals enters the water collection tank 1 through the waste water pipeline, where centralized collection and preliminary stabilization are performed, and the outlet of the water collection tank 1 is connected to the coarse grid 2 through the waste water pipeline. This removes large-diameter solid substances in industrial wastewater. The outlet of the coarse grid 2 is connected to the primary sedimentation tank 3 through the wastewater pipeline, where insoluble substances in the wastewater are further removed, and the outlet of the primary sedimentation tank 3 is connected to the pH adjustment tank through the wastewater pipeline 4. The wastewater is neutralized here and the pH value is accurately adjusted. The pH value of the outlet water of the pH value adjustment tank 4 is 6.5~8.0 to meet the pH requirements of the protein-heavy m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com