Sodium alginate microsphere with corrosion inhibitor being coated inside, and preparation method and applications thereof

A sodium alginate and corrosion inhibitor technology, which is applied in the direction of microsphere preparation, microcapsule preparation, coating, etc., can solve the problems of weak anti-corrosion performance, low cross-linking degree, poor waterproof performance, etc., and achieve uniform particle size, Effect of large specific surface area and improvement of anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

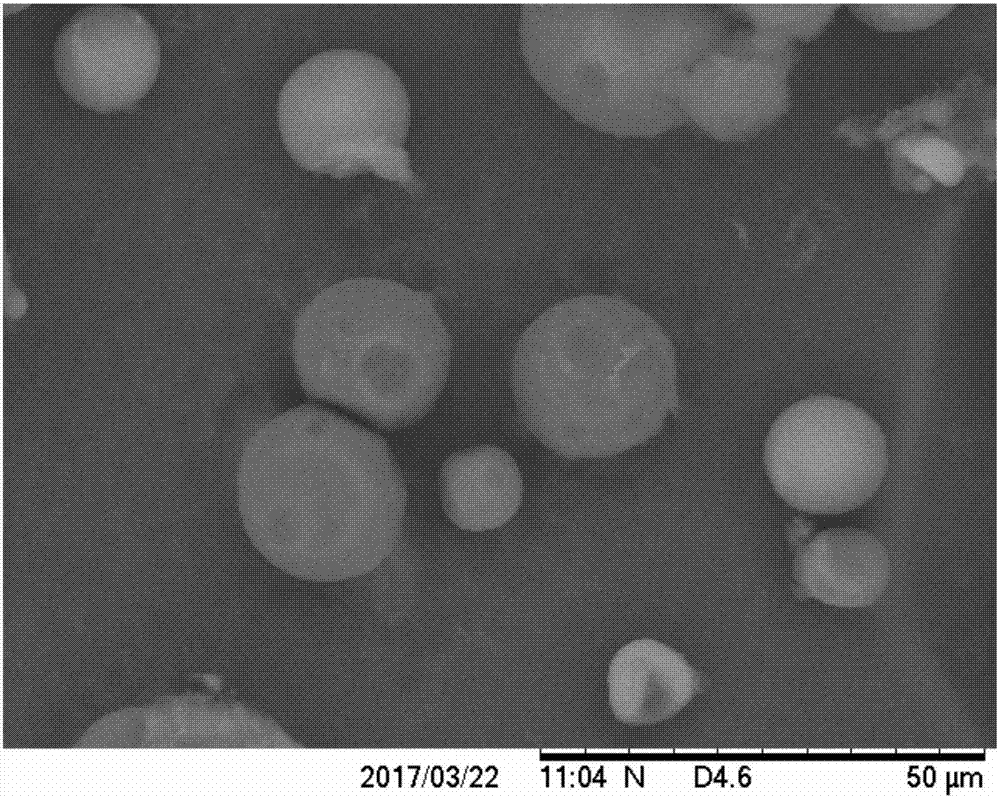

[0029] 1. Preparation of sodium alginate microspheres coated with corrosion inhibitor: mix 2g sodium alginate, 0.2g sodium tartrate, 0.3g calcium carbonate and 98g deionized water, and stir for 24 hours; add 2mL sorbitan oil Ester and 100mL of liquid paraffin were mixed, followed by stirring for 6 hours. Add 10 mL of sodium alginate solution dropwise into 100 mL of liquid paraffin containing sorbitan oleate with a 5 mL syringe, and stir and emulsify for 20 min. Subsequently, 3.3 mL of acetic acid solution was added, and aged with stirring for 6 hours. Then the mixture was centrifuged, and the sodium alginate microspheres were washed several times with petroleum ether and isopropanol respectively. After cleaning, they were placed in a vacuum oven and dried at 30°C to obtain tartaric acid-coated corrosion inhibitors. Sodium alginate microspheres (see figure 1 ).

[0030] Depend on figure 1 It can be seen that the uniform particle size of the prepared sodium alginate microsph...

Embodiment 2

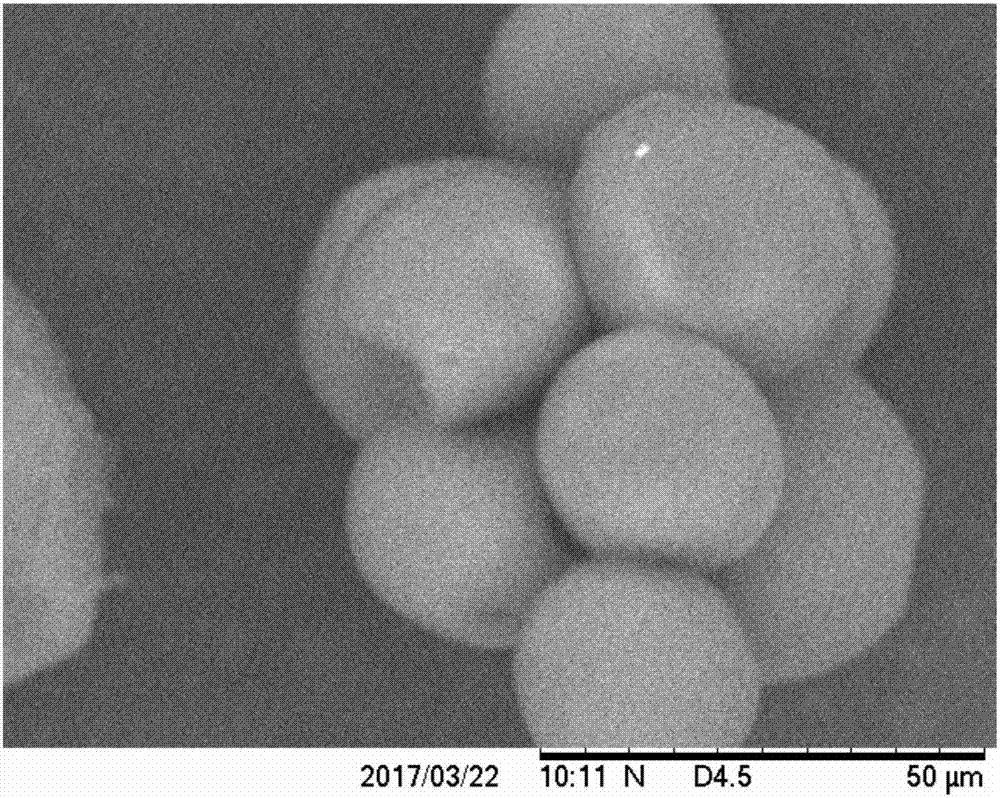

[0035] 1. Preparation of sodium alginate microspheres coated with corrosion inhibitor: mix 2g sodium alginate, 0.1g sodium tartrate, 0.2g calcium carbonate and 97.5g deionized water, and stir for 24 hours; The fatty acid ester and 100 mL of liquid paraffin were mixed, followed by stirring for 6 hours. Add 5 mL of sodium alginate solution dropwise into 100 mL of liquid paraffin containing sorbitan fatty acid ester with a 5 mL syringe, and stir and emulsify for 20 min. Then 2.5 mL of acetic acid solution was added, and aged with stirring for 5 hours. Subsequently, the mixed solution was centrifuged, and the sodium alginate microspheres were washed with petroleum ether and isopropanol for several times. After cleaning, they were placed in a vacuum oven and dried at 25°C to obtain seaweed coated with corrosion inhibitors. Sodium Acetate Microspheres (see figure 2 ).

[0036] Depend on figure 2 It can be seen that the prepared sodium alginate microspheres have complete morpho...

Embodiment 3

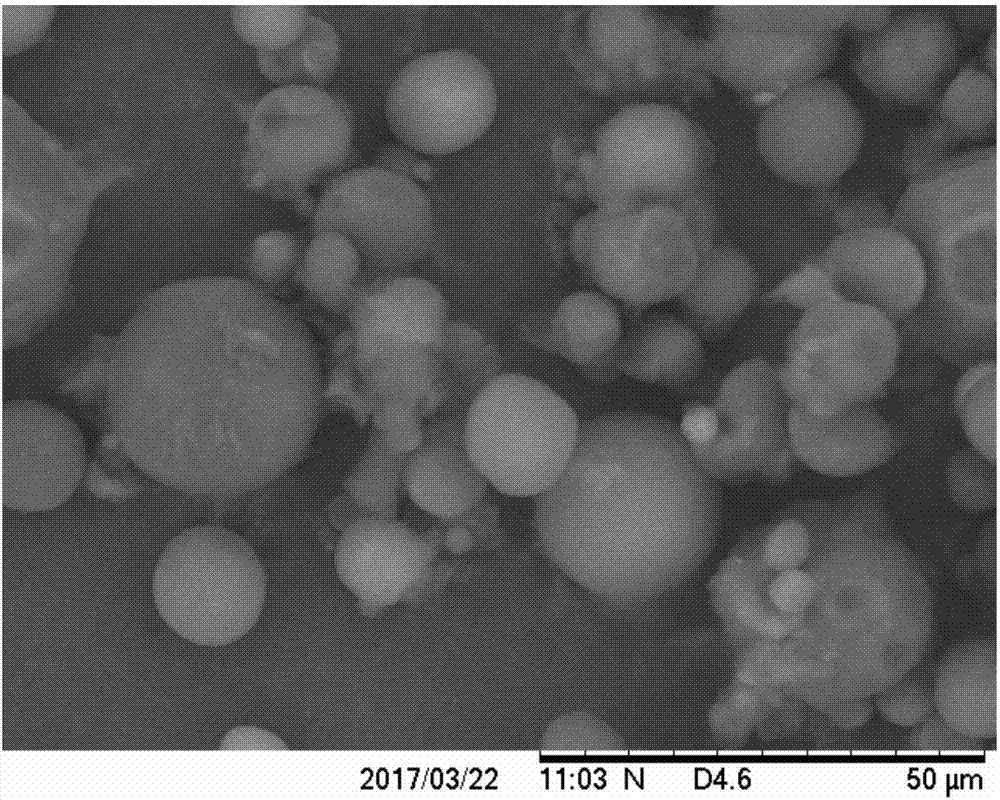

[0039] 1. Preparation of sodium alginate microspheres coated with corrosion inhibitor: Mix 2 g sodium alginate, 0.3 g sodium tartrate, 0.4 g calcium carbonate and 98.5 g deionized water, and stir for 24 hours; 1.5 mL dodecane Sodium base sulfate and 100 mL of liquid paraffin were mixed, followed by stirring for 6 hours. Using a 5mL syringe, add 7mL of sodium alginate solution dropwise into 100mL of liquid paraffin containing sodium dodecyl sulfate, and stir and emulsify for 20min. Subsequently, 4 mL of acetic acid solution was added, and aged with stirring for 7 hours. Then the mixed solution was centrifuged, and the sodium alginate microspheres were washed with petroleum ether and isopropanol several times respectively. After cleaning, they were placed in a vacuum oven and dried at 35°C to obtain seaweed coated with corrosion inhibitors. Sodium Acetate Microspheres (see image 3 ). Depend on image 3 It can be seen that the prepared sodium alginate microspheres have compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com