Hot sol for preparation of aspen wood pencil and preparation method thereof

A hot-melt adhesive and pencil technology, applied in the direction of adhesives, adhesive types, adhesive additives, etc., can solve the problems of difficult to make pencils, short hardening time, low hygroscopicity, etc., achieve good waterproof effect, good durability, Effect of increasing poplar brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

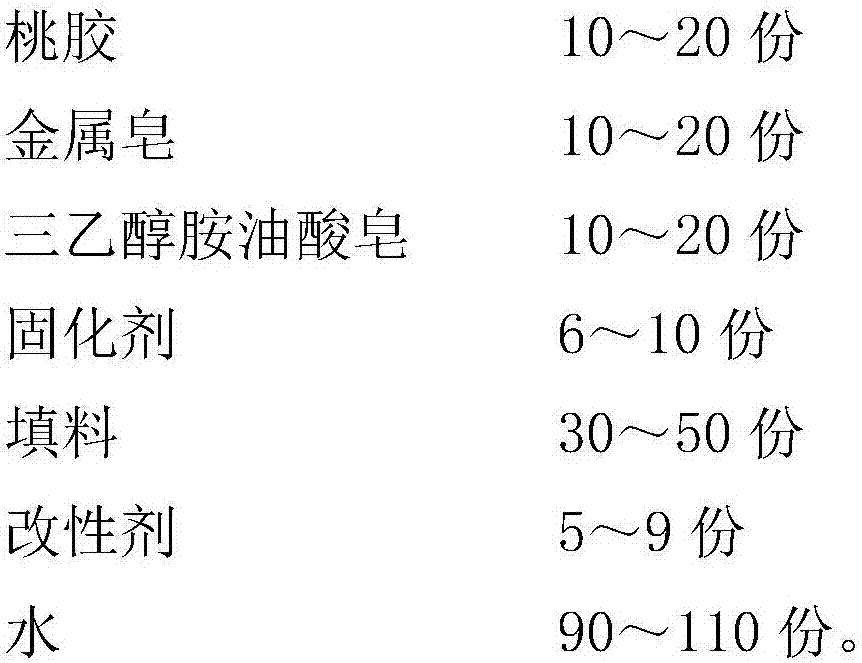

[0022] A kind of poplar wood makes the hot-melt glue of pencil, is made of following raw material components by weight:

[0023]

[0024] The curing agent comprises, by weight, 6 parts of phoxim, 5 parts of disodium dihydrogen pyrophosphate, 2 parts of hydroxypropyl methylcellulose and 1 part of hexamethylenetetramine.

[0025] The curing agent comprises, by weight, 6 parts of phoxim, 2 parts of oxalic acid, 2 parts of methyl salicylate and 1 part of hexamethylenetetramine.

[0026] The filler comprises, by weight, 5 parts of anshi powder, 2 parts of shell powder and 2 parts of heavy calcium carbonate powder.

[0027] The modifying agent comprises, by weight, 5 parts of tannin extract, 3 parts of gelatin and 1 part of glacial acetic acid.

[0028] A kind of preparation method of poplar wood making the hot-melt glue of pencil, comprises the following steps,

[0029] 1) Add UF resin, peach gum, metal soap, triethanolamine oleic acid soap and water to the mixer in turn to fu...

Embodiment 2

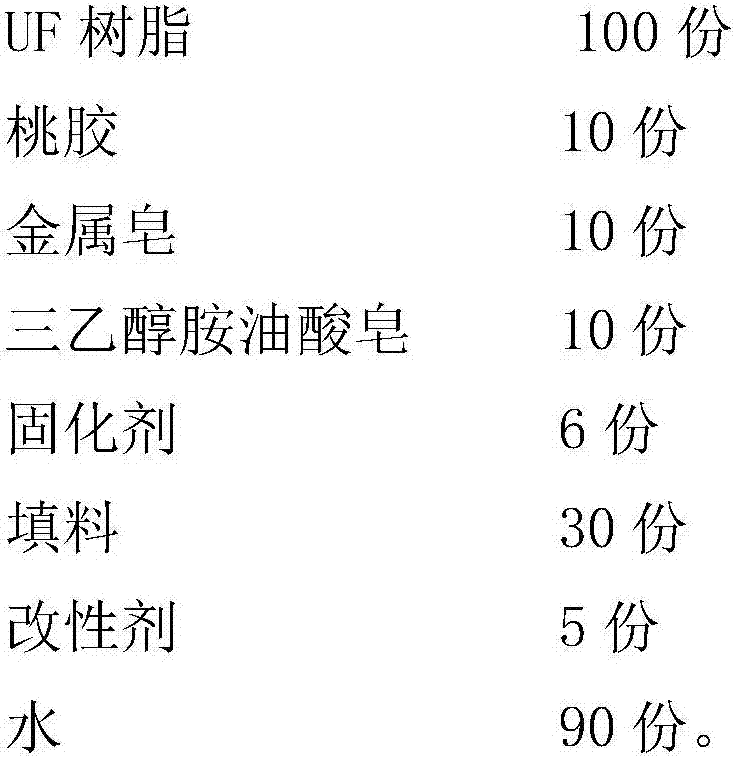

[0036] A kind of poplar wood makes the hot-melt glue of pencil, is made of following raw material components by weight:

[0037]

[0038] The curing agent includes 8 parts of phoxim, 6 parts of disodium dihydrogen pyrophosphate, 2.5 parts of hydroxypropyl methylcellulose and 1.5 parts of hexamethylenetetramine in parts by weight.

[0039] The filler comprises, by weight, 7 parts of anshi powder, 3 parts of shell powder and 3 parts of heavy calcium carbonate powder.

[0040] The modifying agent comprises, by weight, 8 parts of tannin extract, 6 parts of gelatin and 1.5 parts of glacial acetic acid.

[0041] A kind of preparation method of poplar wood making the hot-melt glue of pencil, comprises the following steps,

[0042] 1) Add UF resin, peach gum, metal soap, triethanolamine oleic acid soap and water to the mixer in turn to fully stir and adjust the glue;

[0043] 2) Grind all the solid raw materials, then add all the solid raw materials into the container and mix the...

Embodiment 3

[0049] A kind of poplar wood makes the hot-melt glue of pencil, is made of following raw material components by weight:

[0050]

[0051] The curing agent includes 10 parts of phoxim, 7 parts of disodium dihydrogen pyrophosphate, 3 parts of hydroxypropyl methylcellulose and 2 parts of hexamethylenetetramine in parts by weight.

[0052] The filler comprises, by weight, 8 parts of anshi powder, 4 parts of shell powder and 4 parts of heavy calcium carbonate powder.

[0053] The modifying agent comprises, by weight, 10 parts of tannin extract, 8 parts of gelatin and 2 parts of glacial acetic acid.

[0054] A kind of preparation method of poplar wood making the hot-melt glue of pencil, comprises the following steps,

[0055] 1) Add UF resin, peach gum, metal soap, triethanolamine oleic acid soap and water to the mixer in turn to fully stir and adjust the glue;

[0056] 2) Grind all the solid raw materials, then add all the solid raw materials into the container and mix them th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com