Hollow carbon nano-particles and wave-absorbing material prepared therefrom

A carbon nanoparticle and wave absorbing material technology, applied in the field of wave absorbing materials, can solve the problems of unable to achieve mass production, unable to achieve mass production of pollutants, unable to achieve green and pollution-free, and achieve low density, reduce quality, and improve absorption. The effect of wave performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

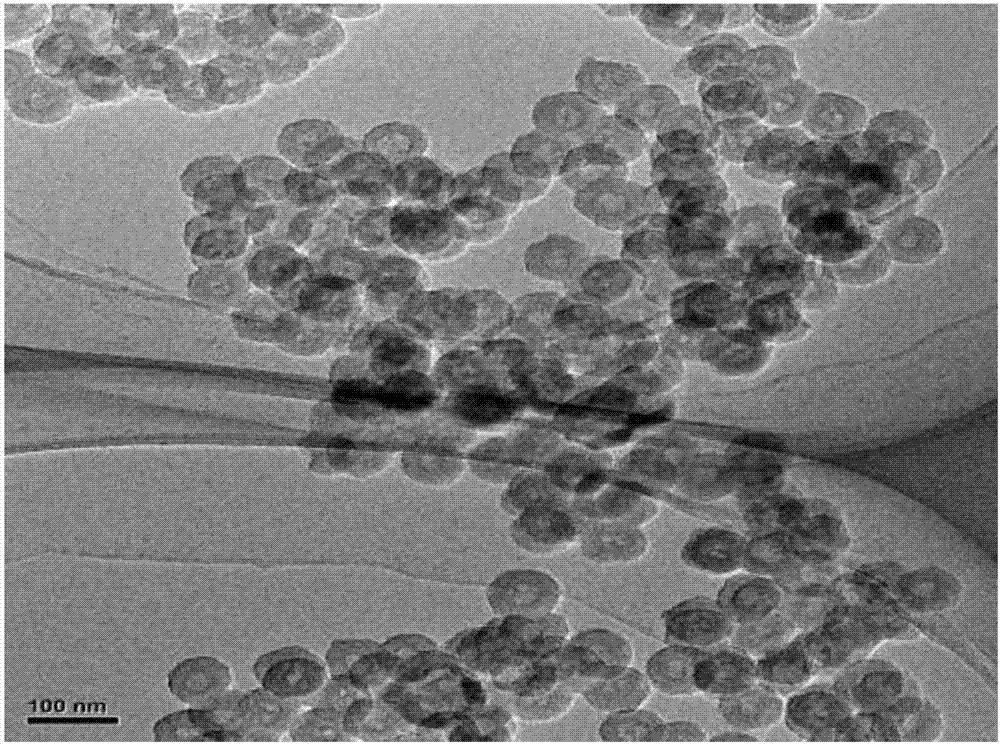

[0054] This embodiment provides a method for preparing hollow carbon nanoparticles, the method comprising the following steps:

[0055] Add 0.76mL of aniline, 0.58mL of pyrrole and 0.06g of non-ionic surfactant Triton X-100 into 120mL of deionized water, stir for 0.5h, sonicate for 0.5h, and then ice-bath for 0.5h to form a clear and transparent solution (this solution is denoted as the first solution); wherein, the temperature of the ice bath is 0°C.

[0056] Dissolve 3.8g of ammonium persulfate in 30mL of deionized water to make an ammonium persulfate solution, and put it in an ice bath for 0.5h (the temperature of the ice bath is 0°C); then add it to the above first solution at one time, when adding, This was added with stirring for about 30 seconds to obtain a second solution.

[0057] React the above second solution at 0°C for 12 hours. After the reaction, use a vacuum filtration device to wash the reacted solution with ethanol solution (ethanol: water = 1:3, volume rati...

Embodiment 2

[0061] This embodiment provides a kind of wave-absorbing material, and the preparation process of this wave-absorbing material is as follows:

[0062] Preparation of graphene powder

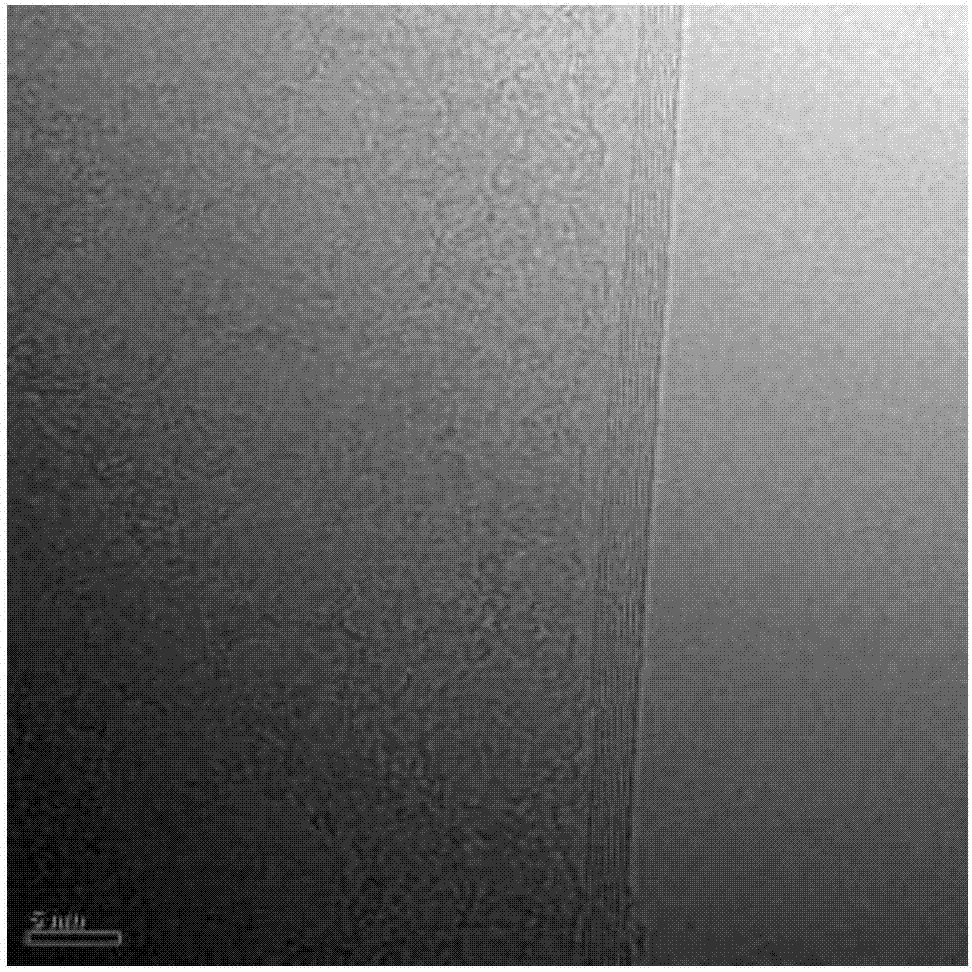

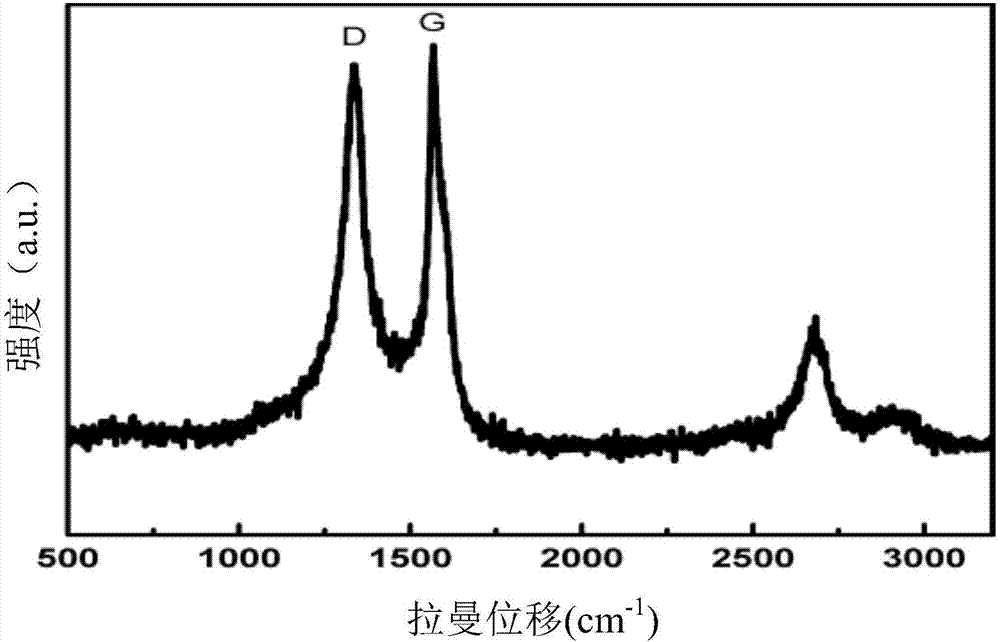

[0063] At room temperature and normal pressure, 100 g of flake graphite and metal balls for ball milling were put into a ball mill jar, and ball milled for 96 hours to obtain a sample in which graphite flakes were exfoliated into graphene powder. The TEM image of the graphene powder is as follows figure 2 As shown, it can be seen from the figure that the number of layers is relatively small, about 8 layers. The Raman spectrum of the graphene powder is as follows image 3 As shown, it can be seen that there are obvious D peaks, indicating that there are many defects in graphene products.

[0064] Preparation of absorbing materials

[0065] The graphene powder obtained above, the hollow carbon nanoparticles provided in Example 1, and polypropylene are added to the torque rheometer according to...

Embodiment 3

[0069] This embodiment provides a kind of wave-absorbing material, and the preparation process of this wave-absorbing material is as follows:

[0070] Preparation of graphene powder

[0071] At room temperature and normal pressure, 10 g of graphite flakes and metal balls for ball milling were put into a ball mill jar, and ball milled for 48 hours to obtain a sample in which graphite flakes were exfoliated into graphene powder.

[0072] Preparation of absorbing materials

[0073] The graphene powder obtained above, the hollow carbon nanoparticles provided in Example 1, and polypropylene are added to the torque rheometer according to the mass ratio of 1:4:19, at 220 ° C, 30r / min Banburying 10min under the condition (the rotating speed of banburying and time and temperature are inversely correlated. The higher the temperature, the smaller the viscosity of the mixture, the smaller the required rotating speed and time), to obtain the mixture;

[0074] The above mixture was hot-pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com