Method for recovering multiple metals from complex antimony-containing gold ore

A multi-metal and gold mining technology, which is applied to the improvement of process efficiency, photography technology, instruments, etc., can solve the problems of secondary pollution, high energy consumption, and the need for pyrotechnics, etc., to achieve efficient recovery, reduce production costs, and reliable strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

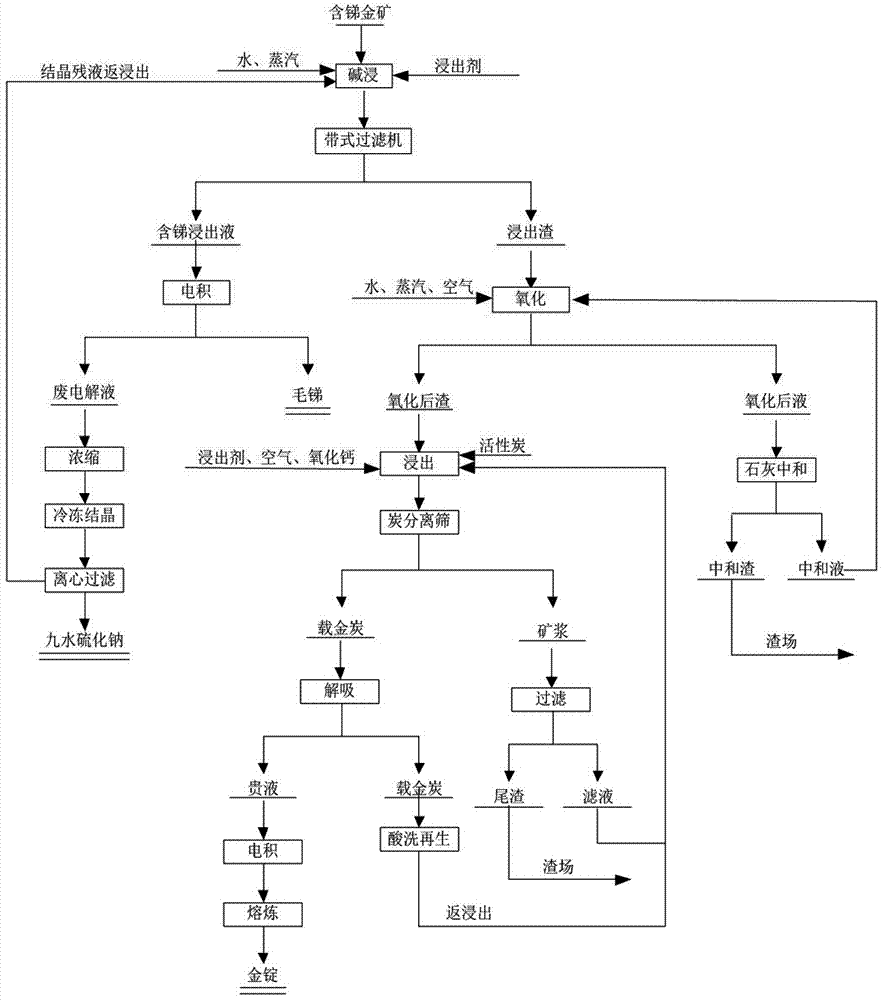

Image

Examples

Embodiment 1

[0016] The composition of antimony gold concentrate is Sb23.5%, Au65g / t, S21.5%.

[0017] Take 2t of antimony-containing gold concentrate.

[0018] 1) Leaching: The antimony-containing gold concentrate ore powder is leached with 10% alkali solution (mixed with sodium sulfide and caustic soda), heated by steam to control the temperature at 75°C, and the leaching reaction time is 1h. The alkali solution and antimony-containing gold concentrate The mass ratio of ore powder is 0.5, oxygen or air is introduced into the leaching process, and the flow rate of oxygen or air is 0.5m 3 / min, filtered after leaching, the filtrate is sent to the electrowinning process, and the filter residue is sent to the gold extraction process;

[0019] 2) Electrodeposition: Step 1) The filtrate produced by leaching is heated to about 40°C, transferred to the electrolytic cell for electrowinning, antimony is precipitated on the cathode steel plate, and the waste electrolyte produced by electrowinning ...

Embodiment 2

[0025] The composition of antimony gold concentrate is Sb35.5%, Au35g / t, S28.5%.

[0026] Take 2t of antimony-containing gold concentrate.

[0027] 1) Leaching: The antimony-containing gold concentrate powder is leached with 35% sodium hydroxide solution, heated by steam to control the temperature at 90°C, and the leaching reaction time is 2.5h. The mass ratio of the alkali solution to the antimony-containing gold concentrate powder is 2. Oxygen or air is introduced during the leaching process, and the flow rate of oxygen or air is 1.5m 3 / min, filtered after leaching, the filtrate is sent to the electrowinning process, and the filter residue is sent to the gold extraction process;

[0028] 2) Electrodeposition: Step 1) The filtrate produced by leaching is heated to about 50°C, transferred to the electrolytic cell for electrowinning, antimony is precipitated on the cathode steel plate, and the waste electrolyte produced by electrowinning is sent to the crystallization process...

Embodiment 3

[0034] The composition of antimony-containing gold concentrate is Sb42.6%, Au185g / t, S16.5%.

[0035] Take 2t of antimony-containing gold concentrate.

[0036] 1) Leaching: The antimony-containing gold concentrate ore powder is leached with 20% circulating alkali solution, heated by steam to control the temperature at 70°C, and the leaching reaction time is 3h. The mass ratio of the alkali solution to the antimony-containing gold ore concentrate ore powder is 3, Oxygen or air is fed into the leaching process, and the flow rate of oxygen or air is 2m 3 / min, filtered after leaching, the filtrate is sent to the electrowinning process, and the filter residue is sent to the gold extraction process;

[0037] 2) Electrodeposition: Step 1) The filtrate produced by leaching is heated to about 45°C, transferred to the electrolytic cell for electrowinning, antimony is precipitated on the cathode steel plate, and the waste electrolyte produced by electrowinning is sent to the crystalliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com