Preparation method of tofacitinib citrate starting material

A technology of tofacitinib and raw materials, applied in the field of chemical pharmacy, can solve the problems of large-scale industrial waste water, increase environmental protection pressure, high price, etc., and achieve the effects of reducing production costs, reducing safety risks, and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

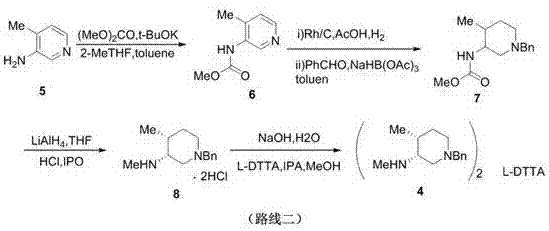

Method used

Image

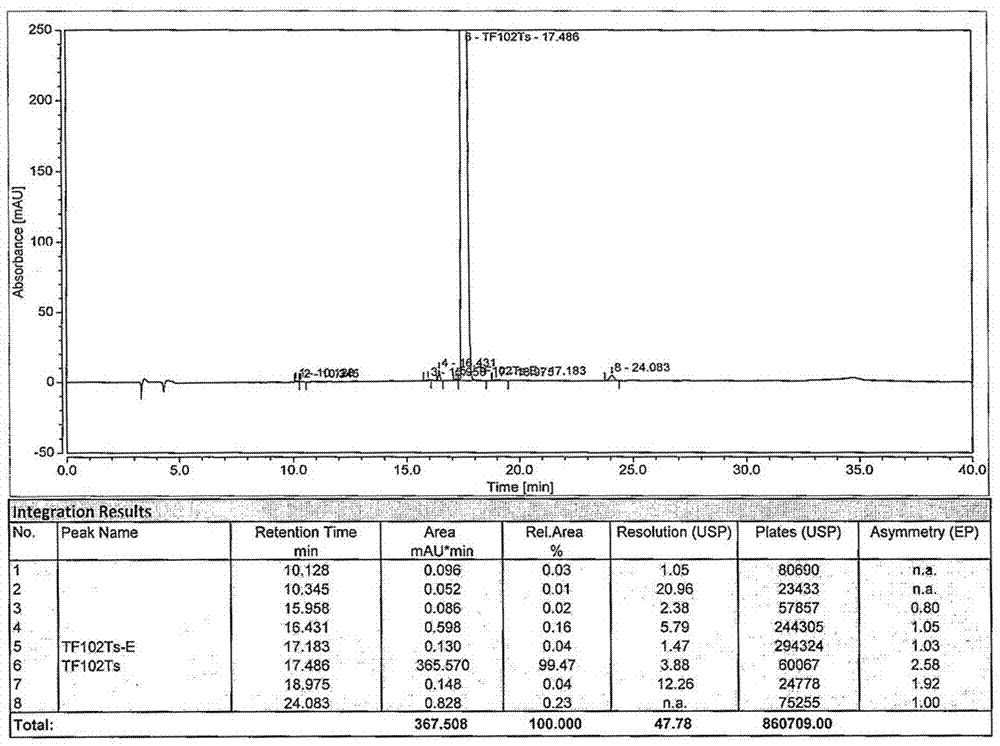

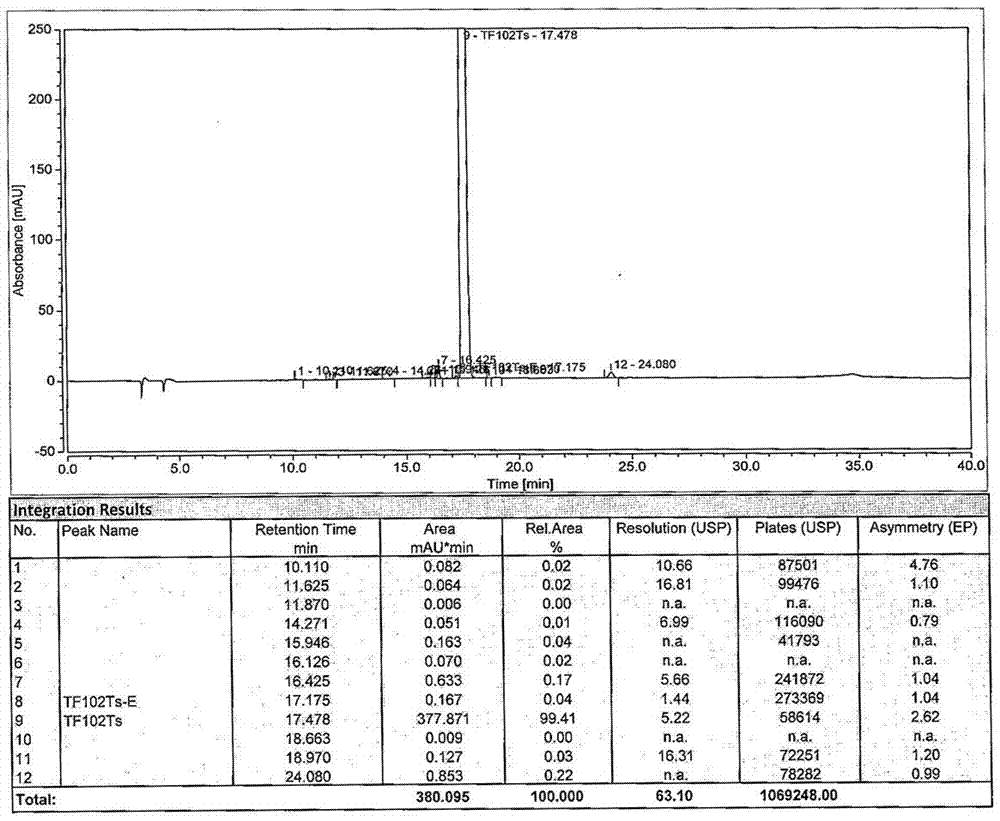

Examples

Embodiment 1

[0035] 1. Synthesis of Compound IV

[0036]Add 50g (1eq) of 4-methylpyridine, 200mL of acetone and 102g (1.5eq) of benzyl chloride into a 500mL reaction flask, start stirring, and keep the reaction for 4 hours; TLC monitors that the reaction is basically complete, cool down to room temperature, and store at an external temperature of 40~45°C Concentrate under reduced pressure to dryness, then add 200mL of acetonitrile to the concentrated solution, raise the temperature to reflux until the solution is clear, then slowly cool down to 0~5°C, stir at this temperature for 2h, filter with suction, and filter the cake with cooled acetonitrile Washed twice, dried to obtain a white solid, and the filter cake was vacuum-dried at 40-45°C to obtain 106.1 g of a white powder, with a yield of 90%.

[0037] 2. Synthesis of Compound V

[0038] Add 100g of compound VI (1.0eq) and 400mL of ethanol to a 1L reaction flask, start stirring, and after cooling down to 15°C, add NaBH to the reaction ...

Embodiment 2

[0048] 1. Synthesis of Compound IV

[0049] Add 100g (1eq) of 4-methylpyridine, 400mL of acetone and 204g (1.5eq) of benzyl chloride into a 1L reaction flask, start stirring, and keep the reaction for 4h; TLC monitors that the reaction is basically complete, cool down to room temperature, and store at an external temperature of 40~45°C Concentrate under reduced pressure to dryness, then add 400mL of acetonitrile to the concentrated solution, raise the temperature to reflux until the solution is clear, then slowly cool down to 0~5°C, stir at this temperature for 2h, filter with suction, and filter the cake with a cooled Washed twice with acetonitrile, drained to obtain a white solid, the filter cake was vacuum-dried at 40-45°C to obtain 212.1 g of white powder, yield 90%.

[0050] 2. Synthesis of Compound V

[0051] Add 200g of compound VI (1.0eq) and 800mL of ethanol to a 2L reaction flask, start stirring, and after cooling down to 15°C, add NaBH to the reaction solution 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com