Aerobic nitrification-anoxic denitrification biological filter tank denitrification system

A biological filter, aerobic nitrification technology, applied in aerobic and anaerobic process treatment, biological water/sewage treatment, water pollutants, etc., can solve the problem of large differences in the generation cycle of microbial populations, high capital investment and operating costs , additional carbon source to increase engineering investment and other issues, to achieve the effect of shortening the film hanging cycle, strong hydrophilicity and bioaffinity, and fast film hanging speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

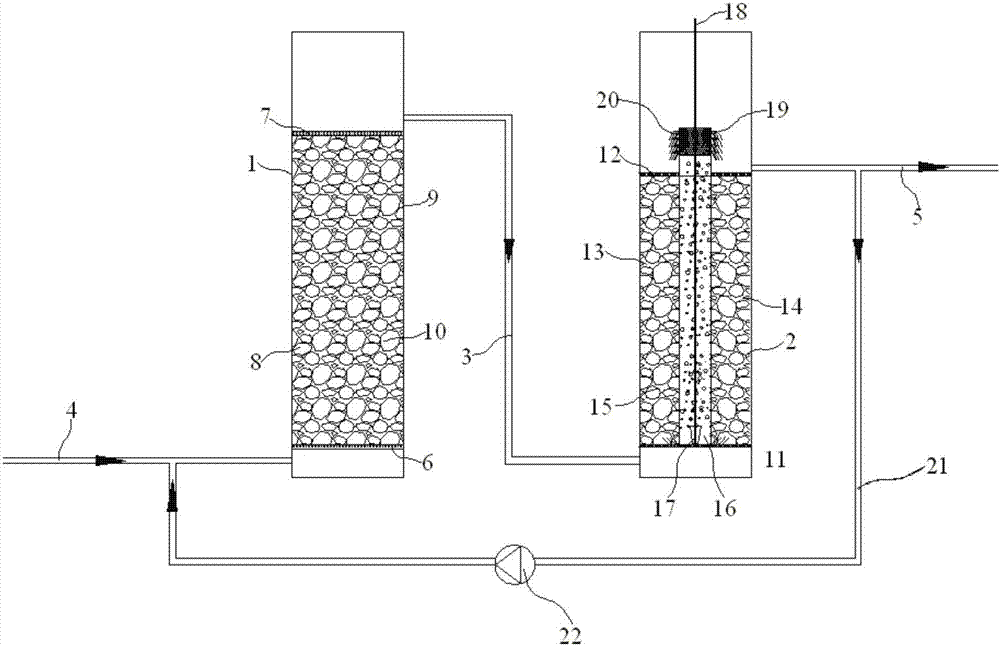

[0042] Embodiment 1~4: a kind of aerobic nitrification-anoxic denitrification biofilter denitrification system, comprises anaerobic pond 1, aerobic pond 2, the upper part of described anaerobic pond 1 and the lower part of aerobic pond 2 pass The intermediate pipe 3 is connected, the bottom of the anaerobic pool 1 is connected with a sewage inlet pipe 4, and the top of the aerobic pool 2 is connected with a drain pipe 5;

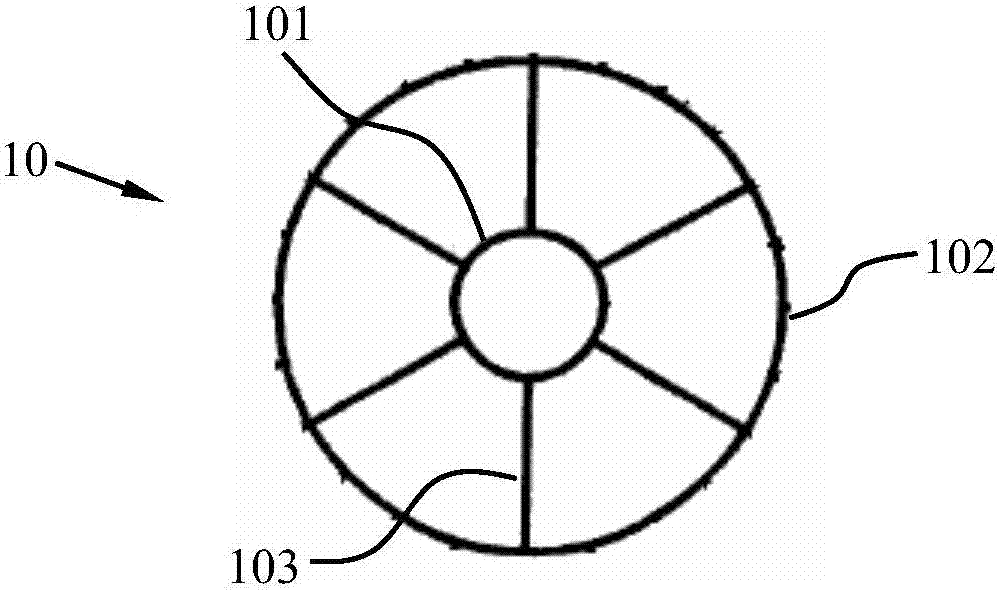

[0043] The lower and upper parts of the anaerobic tank 1 are respectively equipped with a lower support plate 6 and an upper support plate 7. The lower support plate 6, the upper support plate 7 and the side wall of the anaerobic tank 1 form an anaerobic chamber 8. The anaerobic Several anaerobic biological fillers 9 are placed in the cavity 8, and the anaerobic biological fillers 9 are composed of anaerobic carriers 10 and anaerobic microbial films hanging on the surface of the anaerobic carriers 10;

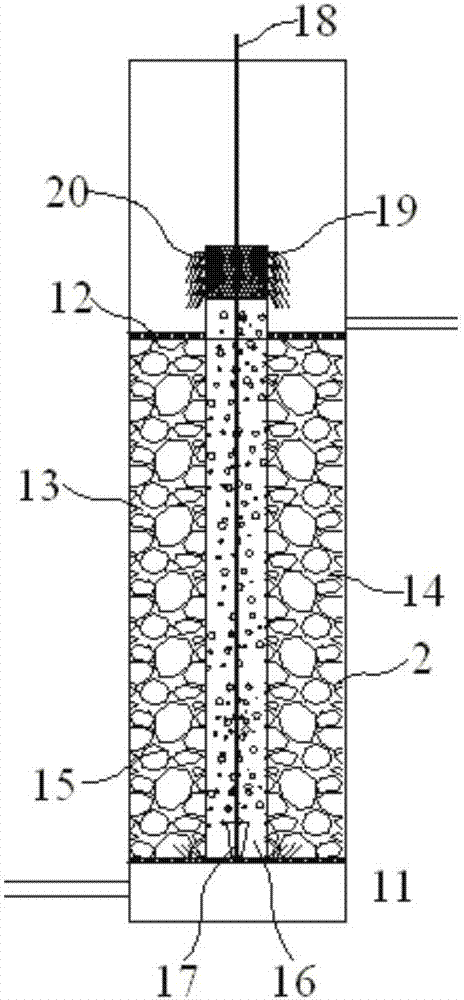

[0044] The bottom and top of the aerobic tank 2 are res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com