A flocculation and impurity removal process of Scutellaria baicalensis extract and its application

A Scutellaria baicalensis extract and flocculation technology are applied in the directions of medical preparations containing active ingredients, plant/algae/fungus/moss components, sugar derivatives, etc. The problem of low extraction rate is to achieve the effect of facilitating subsequent filtration, reducing co-precipitation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

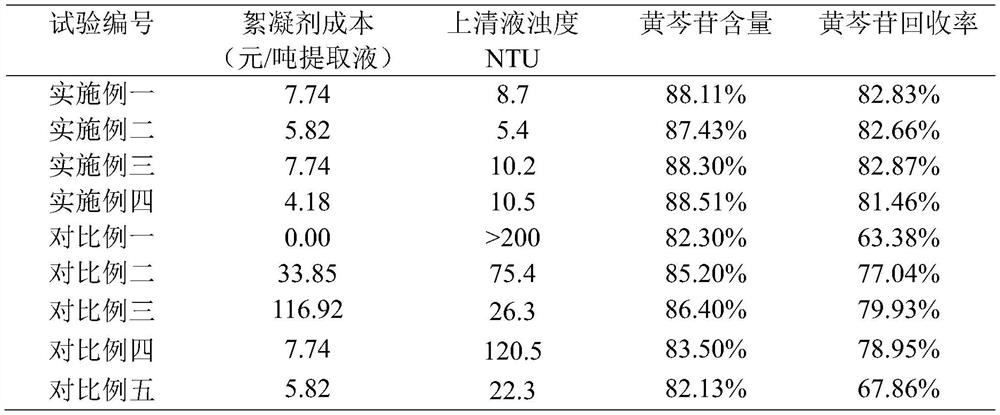

Examples

Embodiment 1

[0054] (1) Take 200 g of Scutellaria baicalensis, slice it, heat it with steam to inactivate enzymes, extract it with 1800 ml of water under reflux for 2 hours, then extract it twice with 700 ml×2 water under reflux, each time for 1 hour, and combine the extracts;

[0055] (2) Heat the extract at 80-90°C, add 50 g of previously prepared bentonite (1%) suspension under stirring, stir evenly, and adjust pH=4.8 with dilute hydrochloric acid;

[0056] (3) Add 42g of 20% calcium chloride solution prepared in advance at 80-90°C, and stir evenly;

[0057] (4) under stirring, adjust the pH value to 5.8-6.0 with 20% sodium hydroxide;

[0058] (5) Leave it to stand at heat preservation, generate large flocs to precipitate, settle for 1 to 2 hours, and take samples to check the flocculation effect;

[0059] (6) filtering the supernatant;

[0060] (7) The filtrate is heated to 80-90° C., and the pH is adjusted to 1.5-2 with hydrochloric acid to generate baicalin precipitation;

[0061]...

Embodiment 2

[0063] (1) Take 200 g of Scutellaria baicalensis, slice it, heat it with steam to inactivate enzymes, extract it with 1800 ml of water under reflux for 2 hours, then extract it twice with 700 ml×2 water under reflux, each time for 1 hour, and combine the extracts;

[0064] (2) Add 42g of 20% calcium chloride solution prepared in advance at 80-90°C, and stir evenly;

[0065] (3) adjust the pH value to 5.8-6.0 with 20% sodium hydroxide under stirring;

[0066] (4) Leave it standing for heat preservation, generate large flocs to precipitate, settle for 1 to 2 hours, and take samples to check the flocculation effect;

[0067] (5) filtering the supernatant;

[0068] (6) The filtrate is heated to 80-90° C., and the pH is adjusted to 1.5-2 with hydrochloric acid to generate baicalin precipitation;

[0069] (7) Filtrate, wash with water, and dry to obtain the crude extract of baicalin.

Embodiment 3

[0071] (1) Take 200g of Scutellaria baicalensis, slice it, heat it with steam to inactivate the enzyme, extract it with 1800ml of water under reflux for 2 hours, then extract it twice with 700ml×2 water under reflux, each time for 1 hour, and combine the extracts, weighing about 2500g;

[0072] (2) Heat the extract at 80-90°C, add 50 g of previously prepared bentonite (1%) suspension under stirring, stir evenly, and adjust pH=4.8 with dilute hydrochloric acid;

[0073] (3) Add 42 g of 20% magnesium chloride solution prepared in advance, and stir for 10 min;

[0074] (4) adjust the pH value to 5.2-5.5 with 20% sodium hydroxide;

[0075] (5) Leave it to stand at heat preservation, generate large flocs to precipitate, settle for 1 to 2 hours, and take samples to check the flocculation effect;

[0076] (6) filtering the supernatant;

[0077] (7) The filtrate is heated to 80-90° C., and the pH is adjusted to 1.5-2 with hydrochloric acid to generate baicalin precipitation;

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com