Three-dimensional porous gold-silver alloy nanometer material and preparation method and application thereof

A technology of three-dimensional porous and nanomaterials, applied in nanotechnology, nanotechnology, analytical materials, etc., can solve the problems of inability to obtain nanocube morphology and limit the application of nanomaterials, and achieve good monodispersity and stability, Strong signal repeatability and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

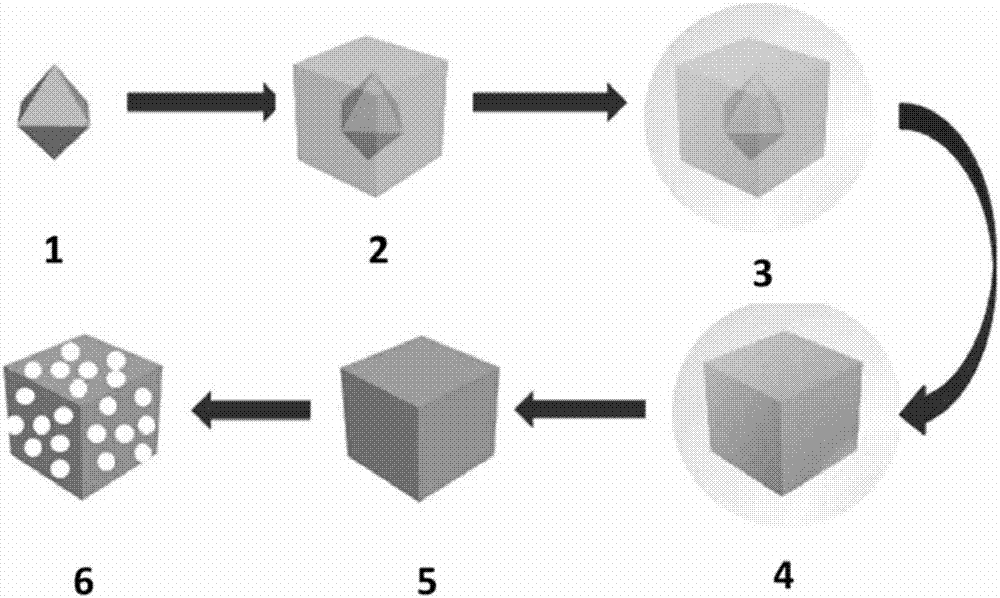

[0035] Specifically, the preparation method of the three-dimensional porous gold-silver alloy nanomaterial may include the following steps:

[0036] Step A, adding silver nitrate to the gold nano-octahedral colloidal solution, so that the concentration of silver nitrate in the mixed liquid is 0.002-0.005mol / L, and reacting at 180-220°C for 32-72 hours, and then centrifuging Separation, the rotational speed of centrifugation is 10000-14500 rev / min, after centrifugation for 30-100 minutes, remove the colorless solution in the centrifuge tube, and then add water to the khaki precipitate obtained by centrifugation to obtain gold@ Silver Nanocube Concentrate. Wherein, the amount of water used is determined according to the amount of the gold nano-octahedral colloidal solution in step A: 0.5-5 mL of water is used for every 10-100 mL of gold nano-octahedral colloidal solution. In practical application, the described gold nano-octahedral colloidal solution can adopt the gold nano-oct...

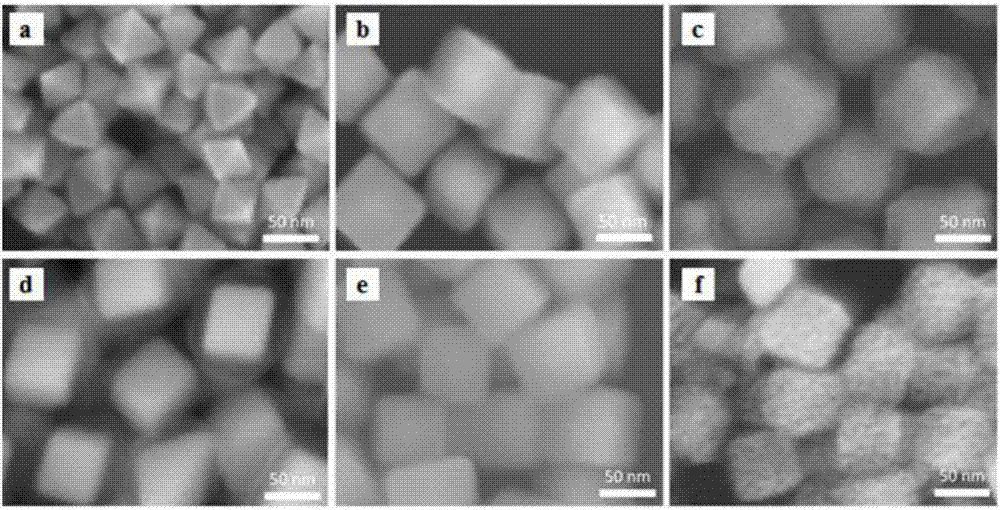

Embodiment 1

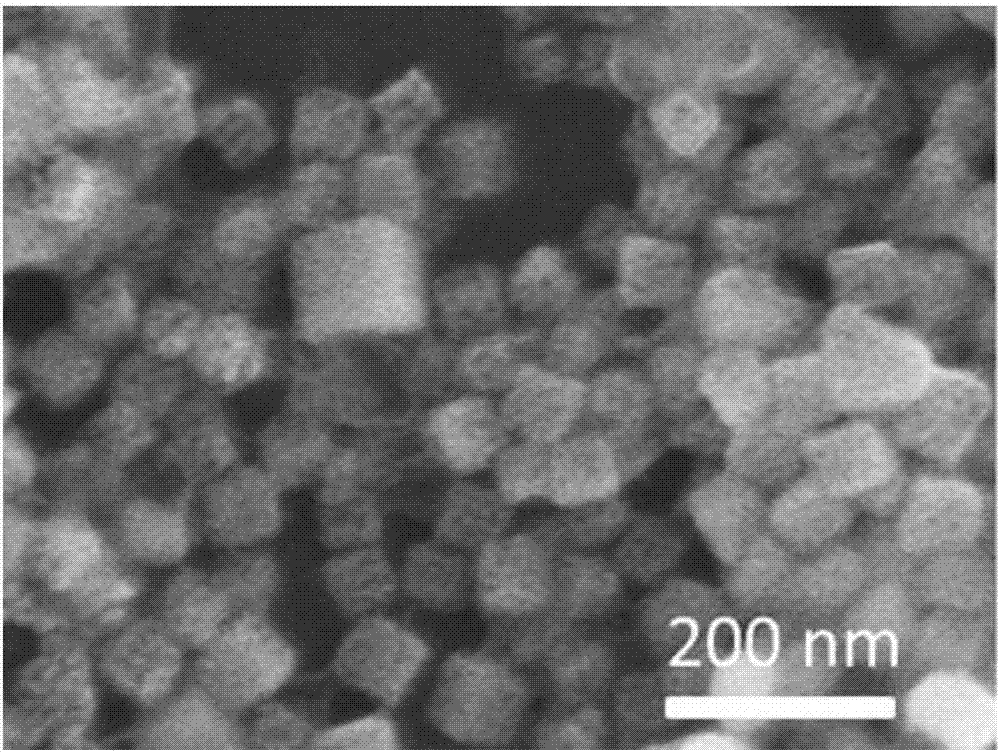

[0053] Such as figure 1 Shown, a kind of three-dimensional porous gold-silver alloy nano material, its preparation method comprises the following steps:

[0054] Step a1, add chloroauric acid and 1.2 milliliters of polydiallyl dimethyl ammonium chloride (Mw=100000~200000, 20wt%) that molecular weight is 100000~200000 in 60 milliliters of ethylene glycol solutions, make the liquid after mixing The concentration of chloroauric acid in the medium is 0.0005 mol / liter, and the concentration of polydiallyl dimethyl ammonium chloride is 0.025 mol / liter, then heated and reacted in an oil bath at 220° C. for 1 hour, and naturally cooled to room temperature. Thereby making gold nano-octahedral colloidal solution (gold nano-octahedral wherein as figure 1 Indicated by the label 1).

[0055] Step b1, add 60 microliters of silver nitrate to 60 milliliters of gold nano-octahedral colloidal solution, remove the magnet after stirring evenly, and react in an oil bath at 220°C for 72 hours, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com