Biological enzyme activated mineral element fertilizer and preparation method thereof

A technology of mineral elements and biological enzymes, applied in fertilizers made of biological waste, animal carcass fertilizers, nitrogen fertilizers, etc., can solve the problems of crop yield reduction and pest infestation, and achieve the effect of improving quality, improving soil and increasing yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention also provides a preparation method of bio-enzyme activated mineral element fertilizer, comprising the following steps:

[0034] a) adding phosphate fertilizer, calcium and magnesium fertilizer, and trace elements to the water, stirring evenly, adding compound strains, stirring evenly, and fermenting for 10-15 days to obtain a fermentation liquid;

[0035] b) adding medical stone powder, amino acid powder, and molasses powder to the fermented liquid obtained in step a), stirring evenly, dehydrating, and crushing and sieving the dehydrated material to obtain a mixture;

[0036] c) extruding and granulating the mixture obtained in step b), and then drying at low temperature to prepare bio-enzyme-activated mineral element fertilizer.

[0037] Here, medical stone powder, phosphate fertilizer, calcium-magnesium fertilizer, amino acid powder, molasses powder, and trace elements are all the same as above, and will not be repeated here.

[0038] The prepar...

Embodiment 1

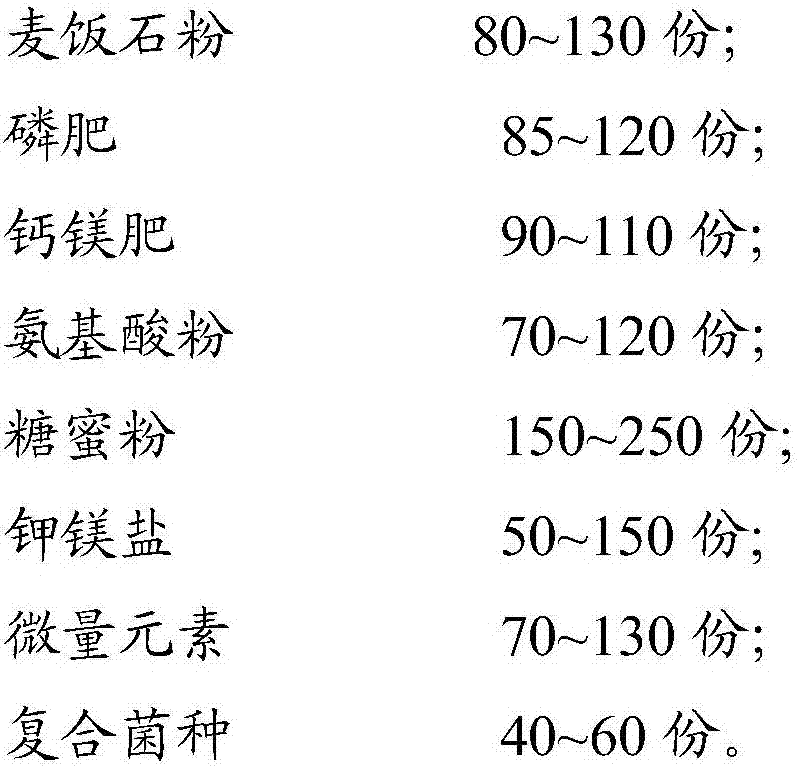

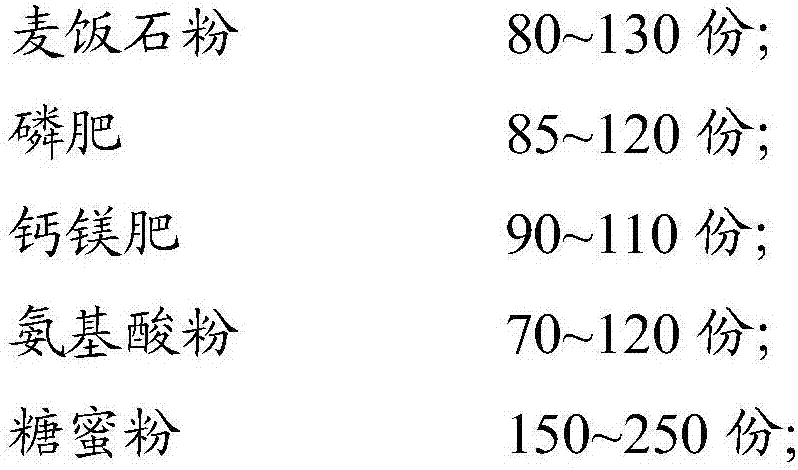

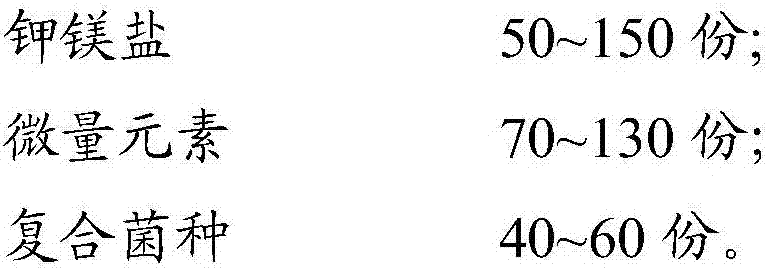

[0042] The bio-enzyme activated mineral element fertilizer includes the following raw materials in parts by weight:

[0043] 90 parts of medical stone powder, 102 parts of guano, 27.73 parts of plant ash, 14.79 parts of superphosphate, 9.25 parts of magnesium phosphate, 36.98 parts of dolomite, 9.25 parts of calcium lignosulfonate, 95 parts of amino acid powder, 190 parts of molasses powder, 90 parts of potassium magnesium salt, 21.43 parts of boric acid, 14.28 parts of manganese sulfate, 12.86 parts of ammonium molybdate, 14.29 parts of copper nitrate, 25.71 parts of ferrous sulfate, 12.86 parts of magnesium chloride, 8.57 parts of zinc sulfate, 2.59 parts of lactic acid bacteria, 10.81 parts of Bacillus subtilis , 1.73 parts of Candida, 2.16 parts of Trichoderma, 3.89 parts of Aspergillus oryzae, 5.41 parts of Sporidium thermophila, 4.32 parts of Saccharomyces cerevisiae, 10.81 parts of Azobacillus, 5.19 parts of Bacillus megaterium and 1.09 parts of Bacillus colioids.

[00...

Embodiment 2

[0049] The bio-enzyme activated mineral element fertilizer includes the following raw materials in parts by weight:

[0050] 80 parts of medical stone powder, 105 parts of animal bone powder, 30.55 parts of plant ash, 14.32 parts of superphosphate, 8.97 parts of magnesium phosphate, 42 parts of dolomite, 9.16 parts of calcium lignosulfonate, 80 parts of amino acid powder, 230 parts of molasses powder, 70 parts Parts of potassium magnesium salt, 24.94 parts of boric acid, 14.02 parts of manganese sulfate, 12.47 parts of ammonium molybdate, 17.15 parts of copper nitrate, 25.71 parts of ferrous sulfate, 15.58 parts of magnesium chloride, 10.13 parts of zinc sulfate, 3.02 parts of lactic acid bacteria, 11.14 parts of Bacillus subtilis, 2.09 parts of Candida, 2.79 parts of Trichoderma, 3.95 parts of Aspergillus oryzae, 5.34 parts of Sporosporium thermophila, 5.11 parts of Saccharomyces cerevisiae, 11.14 parts of Azobacillus, 6.03 parts of Bacillus megaterium and 1.39 parts of Bacill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com