Method for preparing side-chain modified polysiloxane

A polysiloxane, modification technology, applied in the field of synthesis of silicone polymers, can solve the problems of complex preparation process, long cycle, difficult operation, etc., and achieve the effect of simple operation steps, low cost and low condition requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A method for preparing side chain modified polysiloxane, comprising steps as follows:

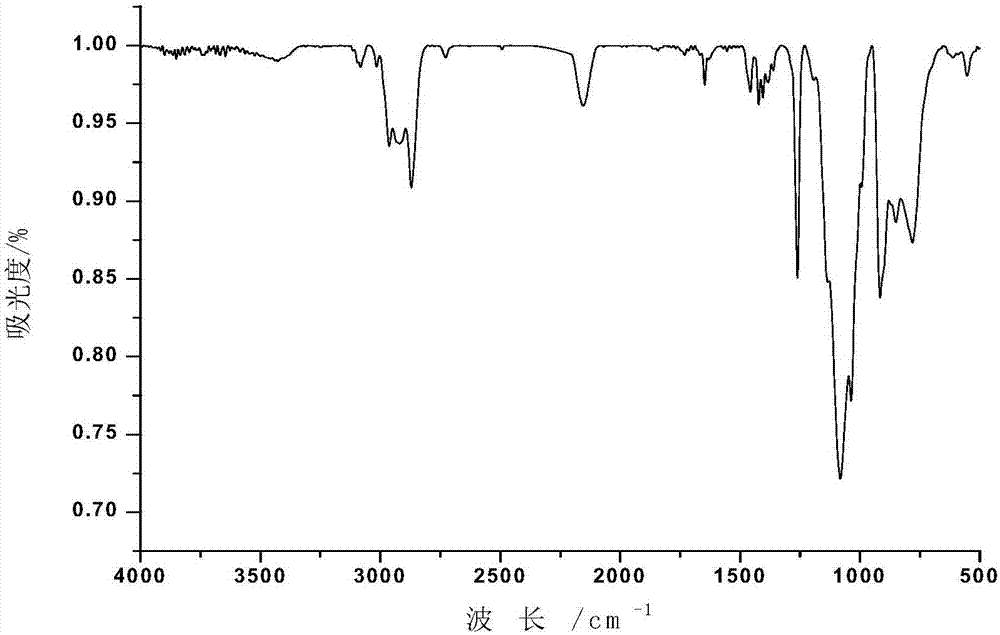

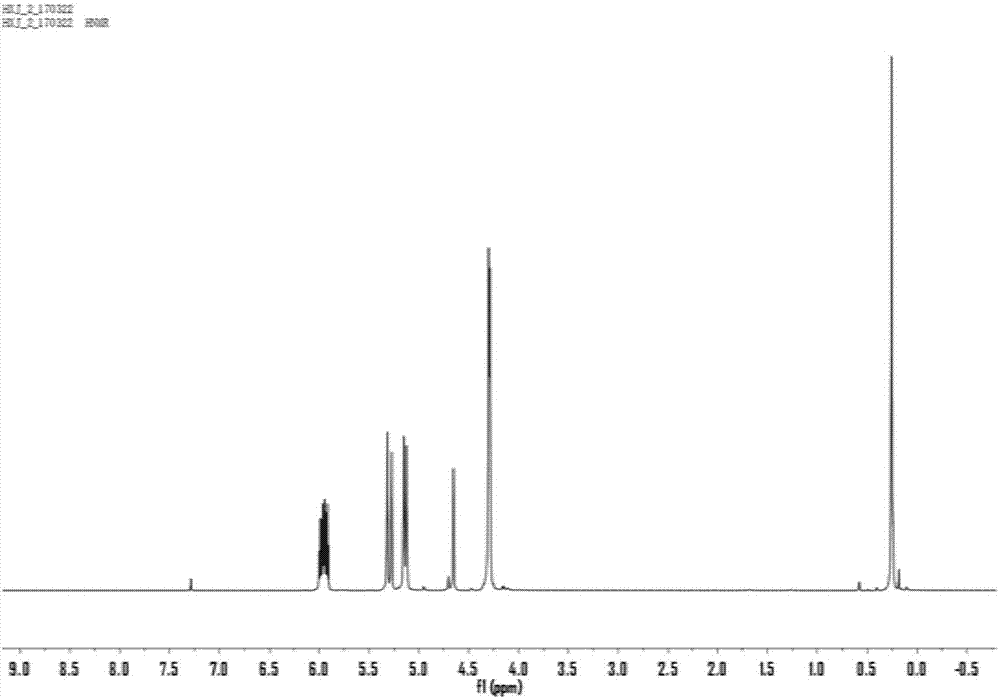

[0047] (1) Under the protection of argon, add dry petroleum ether 120mL, methyl dichlorosilane (55.22g, 0.48mol) in the round-bottomed flask equipped with constant pressure dropping funnel, spherical condenser, thermometer and magneton. Add allyl alcohol (50.57g, 0.87mol) dropwise to the system at a rate of 2mL / min at -10°C, react at 35°C for 3h, distill under reduced pressure after the reaction, collect 40-45°C / 14- 15mmHg fraction, the alcoholysis product bisallyloxymethylsilane 47.37g was obtained, and the yield was 68.9%. The infrared spectrogram and proton nuclear magnetic spectrum spectrogram of alcoholysis product bis-allyloxymethylsilane are as follows figure 1 and figure 2 shown.

[0048] (2) Under argon protection, add dry toluene 60mL, chloroplatinic acid catalyst 30ppm and step (1) gained alcoholysis product (22.87g, 0.14mol ), stirred and reacted at 70° C. for 5 h, and...

Embodiment 2

[0051] A method for preparing side chain modified polysiloxane, comprising steps as follows:

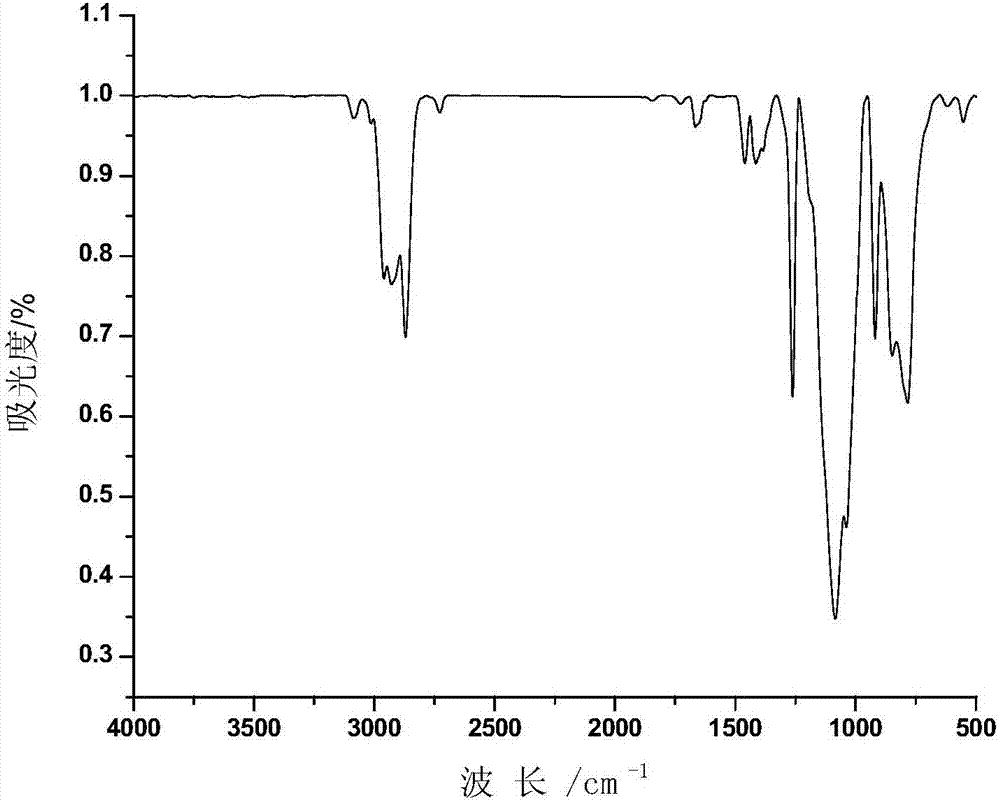

[0052] (1) Under argon protection, add dry cyclohexane 60mL and methyldichlorosilane (25.31g, 0.22mol) into a round bottom flask equipped with a constant pressure dropping funnel, a spherical condenser, a thermometer, and a magnet, At -10°C, allyl alcohol (11.61g, 0.20mol) was added dropwise to the system at a rate of 2mL / min, and reacted at 35°C for 3h. ~15mmHg fraction, the alcoholysis product allyloxymethyl monochlorosilane 19.17g was obtained, and the yield was 70.2%.

[0053] (2) under argon protection, add dry toluene 80mL, chloroplatinic acid catalyst 30ppm and the alcoholysis product (19.17g, 0.14mol) of step (1) gained in the round bottom flask of spherical condenser, thermometer, magneton, The reaction was stirred at 60° C. for 4 h. After the reaction was completed, it was naturally cooled to room temperature. After removing the solvent, 18.21 g of the hydrosilylation pro...

Embodiment 3

[0056] A method for preparing side chain modified polysiloxane, comprising steps as follows:

[0057] (1) Under argon protection, add dry toluene 60mL and methyldichlorosilane (25.31g, 0.22mol) into a round-bottomed flask equipped with a constant pressure dropping funnel, a spherical condenser, a thermometer, and a magnet. Allyl alcohol (11.61 g, 0.20 mol) was added dropwise to the system at a rate of 2 mL / min at 10° C., and reacted at 35° C. for 3 h.

[0058] (2) After the alcoholysis is completed, use an oil pump to pump away the residual hydrogen chloride gas in the system, then add 30 ppm of chloroplatinic acid catalyst into the system, react at 80° C. for 6 hours, and naturally cool to room temperature after the reaction is completed. After removal of the solvent, 18.18 g of the hydrosilylation product was obtained with a yield of 95.7%.

[0059] (3) Add toluene 200mL, step (2) gained hydrosilylation product (8.55g, 0.06mol), hydrochloric acid solution 20mL and two Meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com