Preparation method for mussel protein small peptide and preparation method for corresponding compound chewing tablet of mussel protein small peptide

A technology for chewing tablets and mussels, which is applied in the field of preparation of mussel protein peptides, can solve the problems of increasing the type and dosage of enzymes, single tablet composition, low efficiency, etc., and achieves reduced production costs, high yield, and palatability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

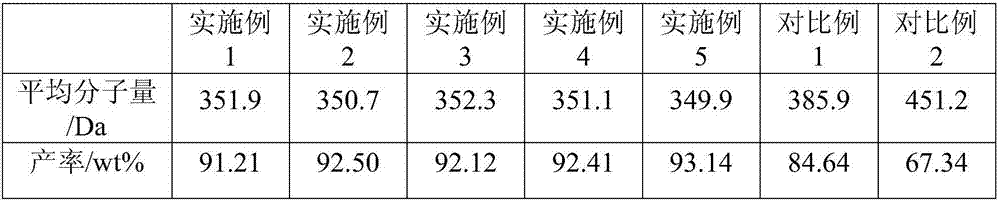

Examples

Embodiment 1

[0039] Select 1000g of fresh mussel meat. After the mussel meat is taken, wash it with clean water to remove impurities and foot silk, control the water, and crush the mussel meat to obtain ground mussel pieces; place it in a tissue masher In homogenization, the mussel protein extract was first adjusted to pH 8.0 with lye, and then neutral protease was added for enzymolysis for 3 hours; then the enzyme was extinguished at 90°C for 4 minutes and the temperature was lowered to 40°C, wherein the neutral protease The weight ratio of protease to mussel pieces is 1:100. Put the mussel protein enzymatic hydrolyzate in a high-pressure tank, pressurize to 3kgf / cm at 110°C 2 , and keep it for 20 minutes to make the pressure uniform, and then suddenly reduce the pressure to 0kgf / cm within 0-3 seconds 2 . Ultrafiltration treatment: small molecules with a molecular weight cut-off of less than 1kDa are passed through an ultrafiltration membrane to obtain small mussel protein peptides, and...

Embodiment 2

[0049] Select 1000g of fresh mussel meat. After the mussel meat is taken, wash it with clean water to remove impurities and foot silk, control the water, and crush the mussel meat to obtain ground mussel pieces; place it in a tissue masher For homogenization, the mussel protein extract was first adjusted to pH 10.0 with lye, then alkaline protease was added for enzymolysis for 1 hour; then the enzyme was extinguished at 100°C for 5 minutes and the temperature was lowered to 50°C. The weight ratio of protease to mussel pieces is 2:100. Put the mussel protein enzymatic hydrolyzate in a high-pressure tank, pressurize to 3kgf / cm at 150°C 2 , and keep it for 10-20 minutes to make the pressure uniform, and then suddenly reduce the pressure to 0kgf / cm within 0-3 seconds 2 . Ultrafiltration treatment: small molecules with a molecular weight cut-off of less than 1kDa are passed through an ultrafiltration membrane to obtain small mussel protein peptides, and the mussel protein small p...

Embodiment 3

[0059] Select 1000g of fresh mussel meat. After the mussel meat is taken, wash it with clean water to remove impurities and foot silk, control the water, and crush the mussel meat to obtain ground mussel pieces; place it in a tissue masher For homogenization, the mussel protein extract was first adjusted to pH 10.0 with lye, then added with alkaline protease, and enzymatically hydrolyzed for 2 hours; then the enzyme was extinguished at 100°C for 4 minutes, and then the temperature was lowered to 45°C, wherein the alkaline protease The weight ratio to mussel pieces is 3:100. Put the mussel protein enzymatic hydrolyzate in a high-pressure tank, pressurize to 3kgf / cm at 110-150°C 2 , and keep it for 120 minutes to make the pressure uniform, and then suddenly reduce the pressure to 0kgf / cm within 0-3 seconds 2 . Ultrafiltration treatment: small molecules with a molecular weight cut-off of less than 1kDa are passed through an ultrafiltration membrane to obtain small mussel protei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com