Perovskite/silicon heterojunction two-end laminated solar cell

A technology of stacked solar and silicon heterojunctions, applied in the field of solar cells, can solve the problems of unsatisfactory top-bottom cell process compatibility and high difficulty in the preparation of perovskite/silicon heterojunction stacked solar cells, so as to improve the stacking performance. Layer cell fill factor, reduced carrier recombination, reduced charge accumulation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

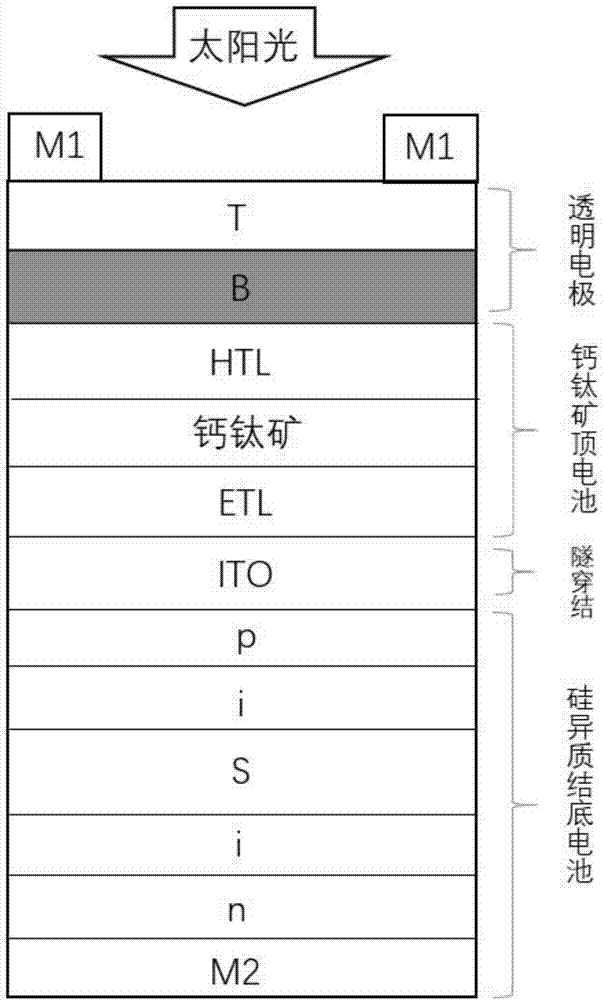

[0024] The structure of a perovskite / silicon heterojunction two-terminal laminated solar cell in the prior art of this embodiment includes, from top to bottom: a metal grid line electrode M1, a transparent electrode T, and a perovskite top cell spacer. Hole transport material layer HTL, perovskite absorption layer, top cell electron transport layer ETL, tunnel junction ITO, silicon heterojunction bottom cell hole selection layer p, passivation layer i, substrate S, passivation layer i, Electron selective layer n and metal back electrode M2.

[0025] The crystalline silicon layer S is n-type polished single crystal silicon.

[0026] The perovskite / silicon heterojunction two-terminal tandem solar cell of this embodiment is prepared by the following method:

[0027] 1. Place the polished Cz silicon wafer substrate with N-type crystal orientation in a PECVD system with high vacuum, and deposit a layer of intrinsic amorphous silicon passivation layer i on the front and back surfa...

Embodiment 2

[0036] The structure of a perovskite / silicon heterojunction two-terminal stacked solar cell applying the technology of the present invention in this embodiment is as follows image 3 As shown, it includes from top to bottom: metal grid line electrode M1, transparent electrode T, intermediate protective layer B, perovskite top cell hole transport layer HTL, perovskite absorption layer, top cell electron transport layer ETL, tunnel Through junction ITO, silicon heterojunction bottom cell hole selection layer p, passivation layer i, substrate S, passivation layer i, electron selection layer n and metal back electrode M2.

[0037] The crystalline silicon layer S is n-type polished single crystal silicon.

[0038] The perovskite / silicon heterojunction two-terminal tandem solar cell of this embodiment is prepared by the following method:

[0039] 1. Place the polished Cz silicon wafer substrate with N-type crystal orientation in a PECVD system with high vacuum, and deposit a layer...

Embodiment 3

[0048]The structure of a perovskite / silicon heterojunction two-terminal tandem solar cell in this embodiment is as follows image 3 As shown, it includes from top to bottom: metal grid line electrode M1, transparent electrode T, intermediate protective layer B, perovskite top cell hole transport layer HTL, perovskite absorption layer, top cell electron transport layer ETL, tunnel Through junction ITO, silicon heterojunction bottom cell hole selection layer p, passivation layer i, substrate S, passivation layer i, electron selection layer n and metal back electrode M2.

[0049] The crystalline silicon layer S is n-type polished single crystal silicon.

[0050] The perovskite / silicon heterojunction two-terminal tandem solar cell of this embodiment is prepared by the following method:

[0051] 1. Place the polished Cz silicon wafer substrate with N-type crystal orientation in a PECVD system with high vacuum, and deposit a layer of intrinsic amorphous silicon passivation layer i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com