Biomimetic non-uniformity structure bioglass scaffold and preparing method thereof

A bioglass, uniform technology, applied in the direction of tissue regeneration, medical science, prosthesis, etc., can solve the problems of affecting the mechanical properties of materials, unfavorable cell proliferation and vascular ingrowth, unfavorable cell adhesion and migration, etc., and achieves a simple and practical preparation method, The effect of good biological activity and easy control of process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The preparation of the biomimetic heterogeneous structure bioactive glass scaffold uses modeling software and 3D printing technology to shape the material, including the following steps and processes:

[0041] (1) Construction of bionic heterogeneous structure

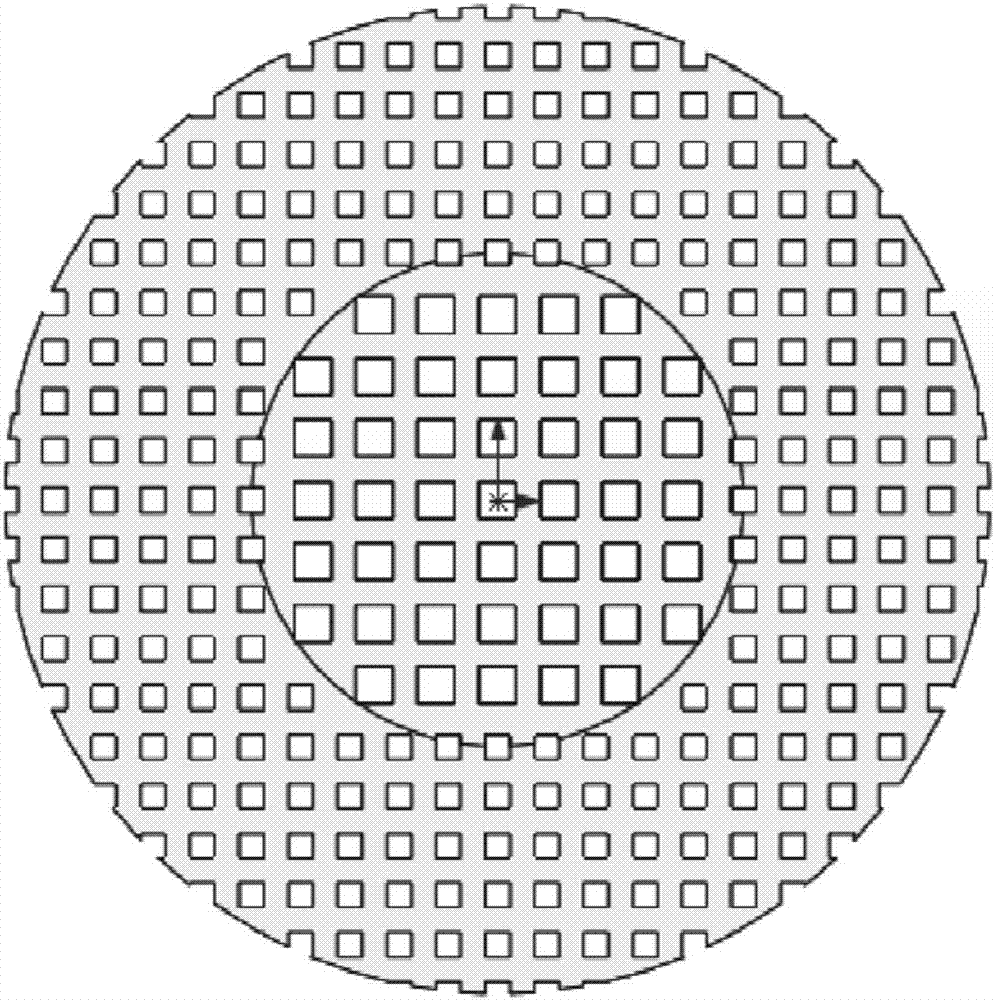

[0042] (1) Use Solidworks software to construct a three-dimensional model of a concentric cylinder with an outer diameter of 16mm, an inner diameter of 5mm, and a height of 4mm;

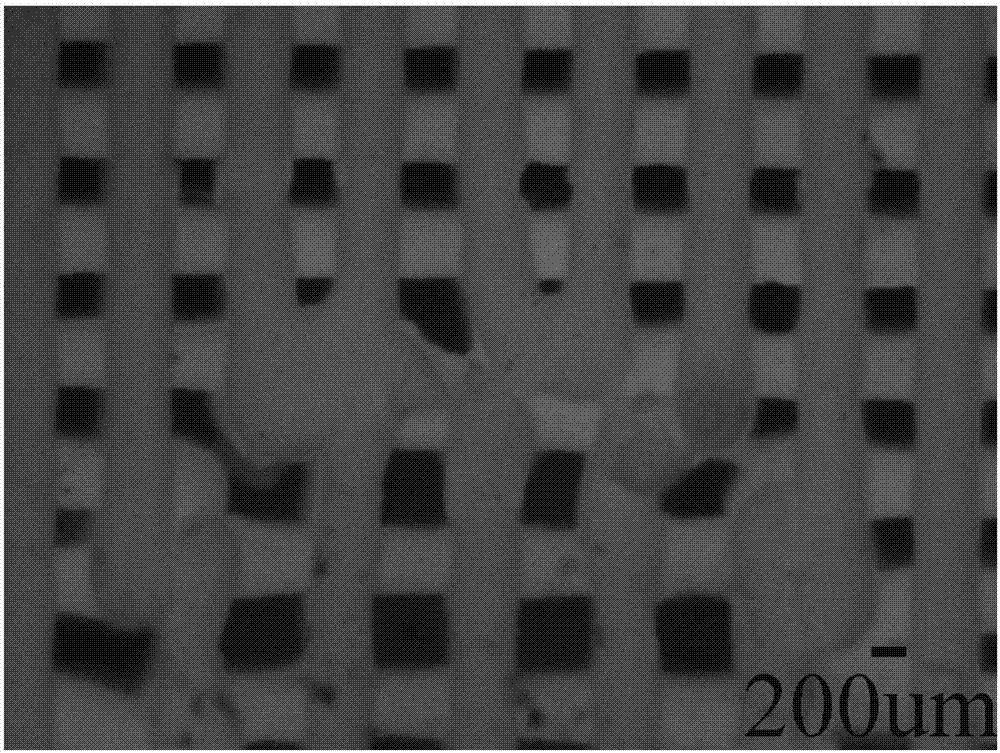

[0043] (2) Import the model into 3D-bioplotter software and Visual machine software for layering and internal structure design. The layer spacing is set to 0.32mm, the outer circle fiber spacing is set to 0.8mm, the inner circle fiber spacing is set to 1mm, and the fiber direction is set to 0° for the x-axis and 90° for the y-axis.

[0044] (2) Preparation of bioglass scaffolds with heterogeneous structure

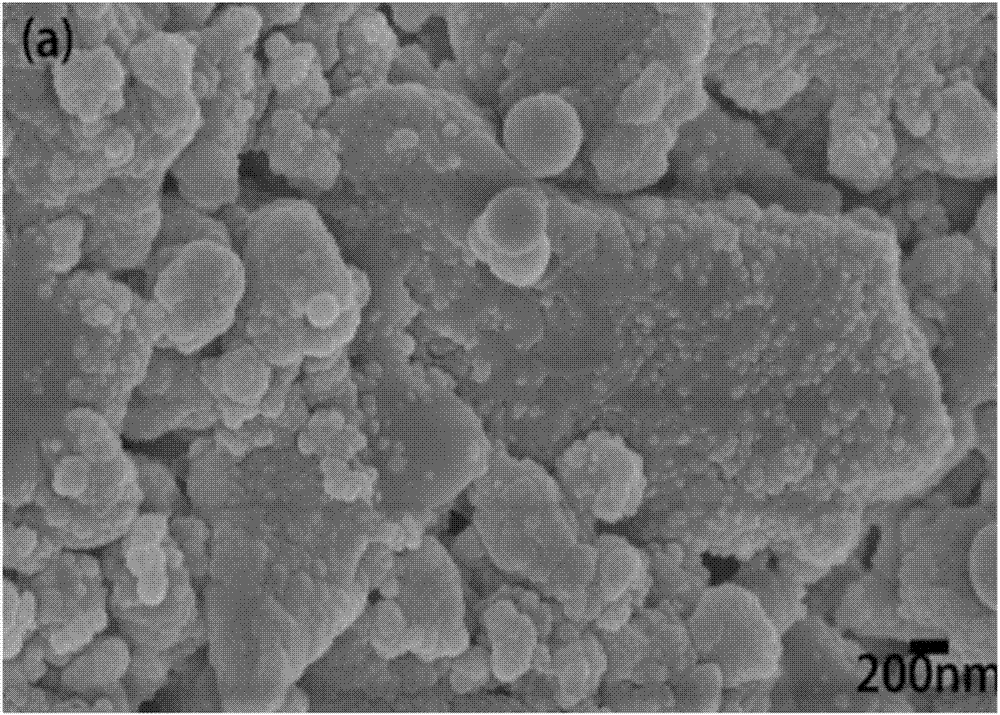

[0045] (1) Add 30 parts by weight of glycerin and 30 parts by weight of ethanol to 70 parts by weight of deionized water, stir ...

Embodiment 2

[0053] The preparation of the biomimetic heterogeneous structure bioactive glass scaffold uses modeling software and 3D printing technology to shape the material, including the following steps and processes:

[0054] (1) Construction of bionic heterogeneous structure

[0055] (1) Use Solidworks software to build a three-dimensional model of a concentric cylinder with an outer diameter of 16mm, an inner diameter of 11mm, and a height of 4mm;

[0056] (2) Import the model into 3D-bioplotter software and Visual machine software for layering and internal structure design. The layer spacing is set to 0.32mm, the outer circle fiber spacing is set to 0.8mm, the inner circle fiber spacing is set to 1mm, and the fiber direction is set to 0° for the x-axis and 90° for the y-axis.

[0057] (2) Preparation of bioglass scaffolds with heterogeneous structure

[0058] (1) Add 30 parts by weight of glycerin and 30 parts by weight of ethanol to 70 parts by weight of deionized water, stir for...

Embodiment 3

[0065] The preparation of the biomimetic heterogeneous structure bioactive glass scaffold uses modeling software and 3D printing technology to shape the material, including the following steps and processes:

[0066] (1) Construction of bionic heterogeneous structure

[0067] (1) Use Solidworks software to build a three-dimensional model of a concentric cylinder with an outer diameter of 16mm, an inner diameter of 8mm, and a height of 4mm;

[0068] (2) Import the model into 3D-bioplotter software and Visual machine software for layering and internal structure design. The layer spacing is set to 0.32mm, the outer circle fiber spacing is set to 0.8mm, the inner circle fiber spacing is set to 1mm, and the fiber direction is set to 0° for the x-axis and 90° for the y-axis.

[0069] (2) Preparation of bioglass scaffolds with heterogeneous structure

[0070] (1) Add 30 parts by weight of glycerin and 30 parts by weight of ethanol to 70 parts by weight of deionized water, stir for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com