Method for preparing wood-plastic material from bean dregs

A technology of wood-plastic materials and bean dregs, which is applied in the field of composite materials, can solve problems such as high cost, high energy consumption, and environmental pollution, and achieve the effects of improved performance, low pollution, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1, the influence of modification mode on the performance of wood-plastic material

[0045] This embodiment is based on the following preparation process:

[0046] (1) Place the wet bean dregs outdoors, dry naturally, collect the bean dregs powder crushed to more than 40 mesh, add industrial hexane to extract and degrease, collect the precipitate, and dry;

[0047] (2) Treatment methods 1-3 adopt different methods to modify the okara powder.

[0048] (3) The okara powder collected in the step 2 of 45 parts by weight is mixed with the HDPE5000S of 40 parts by weight, the maleic anhydride grafted polypropylene of 3 parts by weight, the stearic acid of 1 part by weight, the ethylene glycol of 1 part by weight Ethyl bis stearic acid amide, the calcium carbonate powder of 10 parts by weight are mixed homogeneously;

[0049] (4) Place the mixture obtained in step 3 in an open mixer, heat-melt and mix at a high temperature of 180° C. for 4 minutes, and place the pr...

Embodiment 2

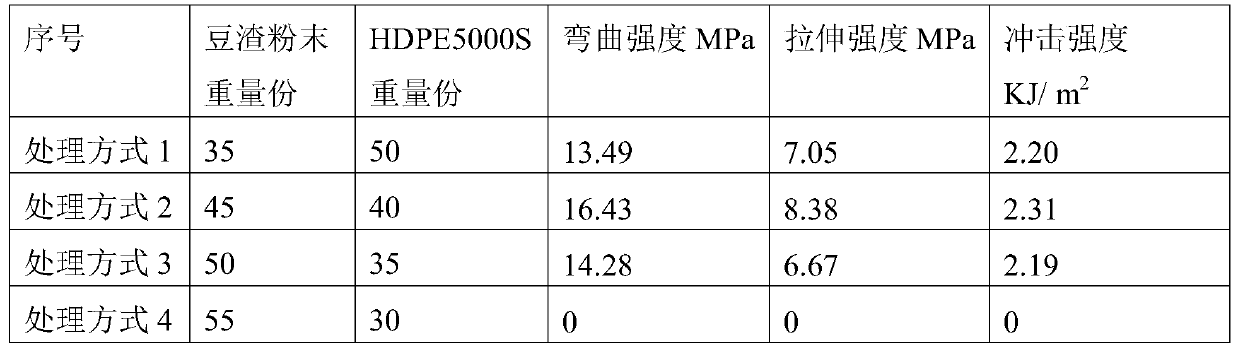

[0058] Embodiment 2, the influence of plastic ratio on the performance of wood-plastic material

[0059] This embodiment is based on the following preparation process:

[0060] (1) Put the wet bean dregs outside, collect the bean dregs powder crushed to more than 40 mesh after natural air-drying, add industrial hexane to extract and degrease, collect the precipitate, and dry;

[0061] (2) Dry and pulverize the precipitate in step 1, add water according to the ratio of 1:20g / mL to water, adjust the pH to 12, react in a constant temperature shaking water bath at 80°C for 2 hours, collect the precipitate, dry and pulverize to above 40 mesh.

[0062] (3) the processed okara powder collected in step 2 and HDPE5000S, 3 parts by weight of maleic anhydride grafted polypropylene, 1 part by weight of stearic acid, 1 part by weight of ethylene bis stearic acid amide, 10 parts by weight of calcium carbonate powder are uniformly mixed; treatment modes 1 to 4 respectively use different par...

Embodiment 3

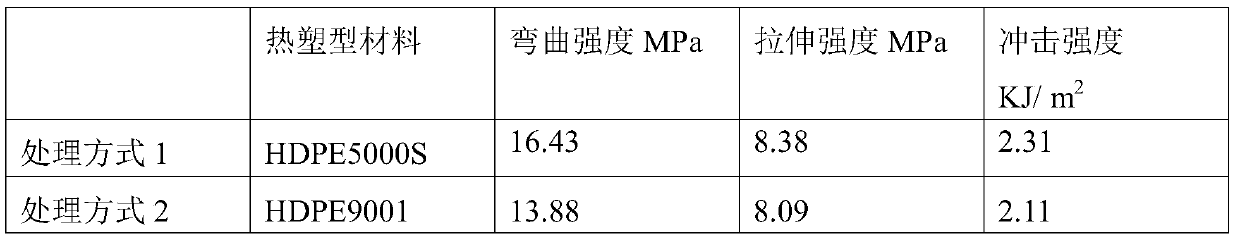

[0069] Embodiment 3, the influence of plastic type on the performance of wood-plastic material

[0070] This embodiment is based on the following preparation process:

[0071] (1) Put the wet bean dregs outside, collect the bean dregs powder crushed to more than 40 mesh after natural air-drying, add industrial hexane to extract and degrease, collect the precipitate, and dry;

[0072] (2) Dry and pulverize the precipitate in step 1, add water according to the ratio of 1:20g / mL to water, adjust the pH to 12, react in a constant temperature shaking water bath at 80°C for 2 hours, collect the precipitate, dry and pulverize to above 40 mesh.

[0073] (3) The okara powder collected in the step 2 of 45 parts by weight and the thermoplastic material of 40 parts by weight, the maleic anhydride grafted polypropylene of 3 parts by weight, the stearic acid of 1 part by weight, the stearic acid of 1 part by weight 10 parts by weight of ethylene bis stearic acid amide (EBS) and 10 parts by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com