Gelatin chitosan-nano-silicon dioxide multi-core phase-change energy-storage microcapsule preparation method

A nano-silica, phase-change energy storage technology, applied in the field of medicine, achieves the effects of simple preparation method, increased affinity, and improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

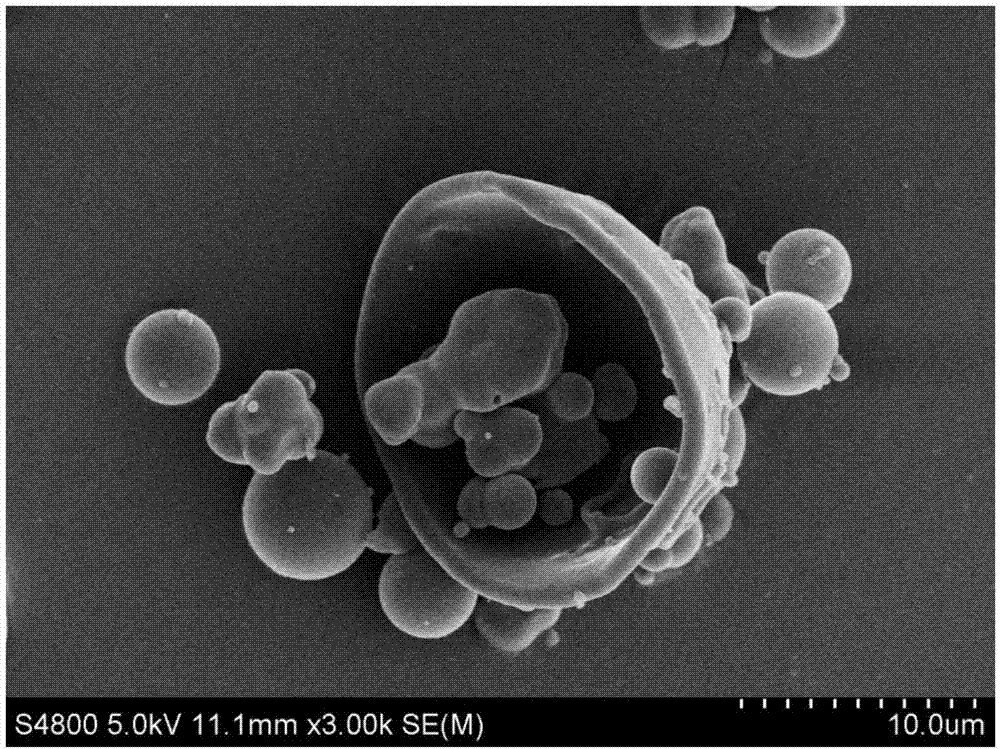

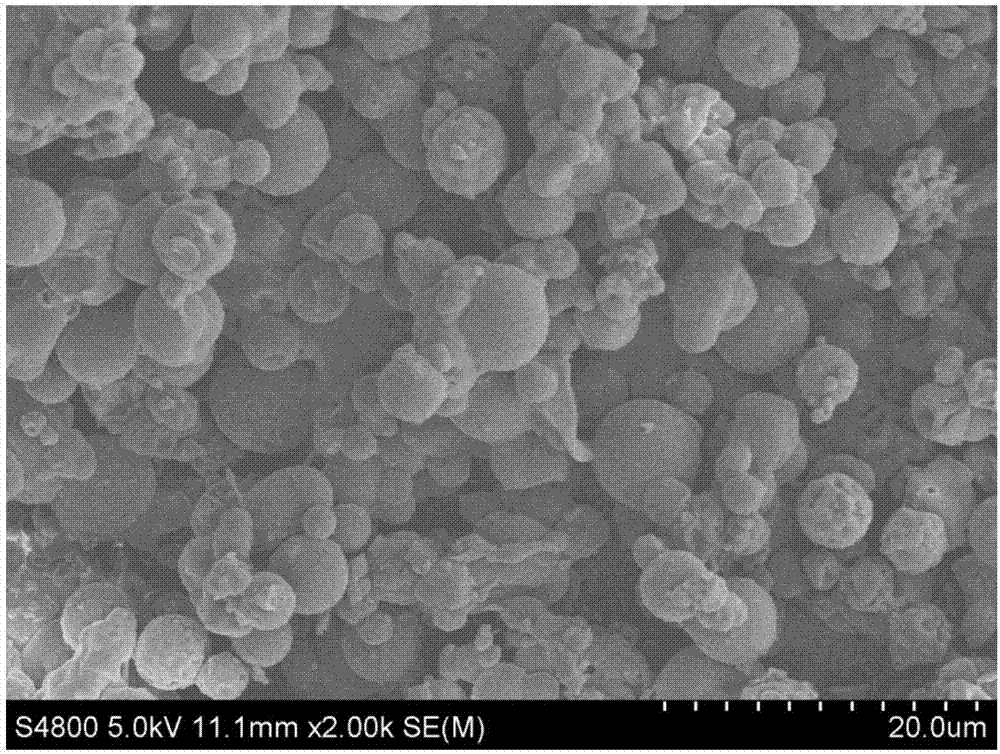

Image

Examples

Embodiment 1

[0032] Step 1, dissolve 0.15g chitosan in 2% acetic acid solution to prepare 3g 5% chitosan solution, and add 0.0038g nano silicon dioxide to the chitosan solution, ultrasonically disperse for 30min to obtain chitosan Sugar / SiO 2 Dispersions;

[0033] Step 2, 0.15g gelatin is mixed with distilled water into 10% gelatin solution;

[0034] Step 3, mix 3g of paraffin with the chitosan / SiO obtained in step 1 2 Mix the solutions, add 0.18g Span80 as an emulsifier, and emulsify at 60°C and 2000r / min for 40min to form an emulsion;

[0035] Step 4, slowly add the gelatin solution in step 2 to the emulsion obtained in step 3, and at the same time add 0.0002 glutaraldehyde solution dropwise, stir and solidify at 60°C and 800r / min for 60min to obtain a composite microcapsule suspension;

[0036] In step 5, the composite microcapsule suspension obtained in step 4 is washed twice with n-hexane, ethanol and acetone in sequence, and dried to obtain solid powder of multi-nuclear phase chan...

Embodiment 2

[0039] Step 1, dissolve 0.15g chitosan in 2% acetic acid solution to prepare 3g 5% chitosan solution, and add 0.015g nano silicon dioxide to the chitosan solution, ultrasonically disperse for 30min to obtain chitosan Sugar / SiO 2 Dispersions;

[0040] Step 2, prepare 0.75g of gelatin with distilled water into a 10% gelatin solution, and add 0.0188g of nano silicon dioxide to the gelatin solution, and ultrasonically disperse for 30min to obtain gelatin / SiO 2 Dispersions;

[0041] Step 3, mix a mixture of 11.25 g paraffin and 3.75 g dodecanol with the chitosan / SiO from step 1 2 Mix the solutions, add 1.8g Span80 as an emulsifier, and emulsify at 50°C and 2000r / min for 60min to form an emulsion;

[0042] Step 4, the gelatin / SiO in step 2 2 The solution is slowly added dropwise to the emulsion obtained in step 3, and at the same time, 0.0038 glutaraldehyde solution is added dropwise, and the solidification reaction is stirred at 60°C and 800r / min for 120min to obtain a composit...

Embodiment 3

[0046] Step 1, dissolve 0.15g chitosan in 2% acetic acid solution to prepare 3g 5% chitosan solution;

[0047] In step 2, 0.3 g of gelatin was prepared into a 10% gelatin solution with distilled water, and 0.03 g of nano-silicon dioxide was added to the gelatin solution, and ultrasonically dispersed for 30 min to obtain gelatin / SiO 2 Dispersions;

[0048] Step 3, mix the mixture of 3g paraffin and 3g dodecanol with the chitosan / SiO from step 1 2 The solution was mixed, 0.369g Span80 was added to it as an emulsifier, and emulsified at 80°C and 2000r / min for 30min to form an emulsion;

[0049] Step 4, combine the gelatin / SiO from step 2 2 The solution was slowly added dropwise to the emulsion obtained in step 3, and 0.0009 g of glutaraldehyde solution was added dropwise at the same time, and the solidification reaction was stirred at 60 ° C and 800 r / min for 30 min to obtain a composite microcapsule suspension;

[0050] In step 5, the composite microcapsule suspension obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com