Preparation method of iron oxide-mesoporous carbon lithium ion battery anode material

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as easy crushing and agglomeration, poor conductivity and volume change, and achieve good conductivity, stable chemical properties, and reversible electricity. The effect of high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) 50 parts of resorcinol, 30 parts of urotropine, 80 parts of polyoxyethylene-polyoxypropylene-polyoxyethylene triblock copolymer Pluronic P-123 (PEO 20 -PPO 70 -PEO 20 ) and 20 parts of 1,3,5-trimethylbenzene were dissolved in 170 parts of deionized water, heated and stirred at 30°C for 2 hours, until they were completely dissolved, and a clear solution A was obtained.

[0030] 2) Add 60 parts of ferrous gluconate into the above-mentioned clear solution A, heat and stir at 30° C. for 1 hour, and wait until it dissolves completely to obtain clear solution B.

[0031] 3) Put the above-mentioned clear solution B in a reaction kettle, then place the reaction kettle in an oven at a temperature of 100° C. for heating and reacting for 12 hours, and wash the obtained intermediate product 3 times with water and alcohol.

[0032] 4) The above intermediate product was carbonized in an argon atmosphere, the carbonization temperature was 800° C., and the carbonization time was 3...

Embodiment 2

[0034] 1) Dissolve 60 parts of resorcinol, 40 parts of urotropine, 100 parts of polystyrene-polyoxyethylene-polystyrene triblock copolymer and 25 parts of 1,3,5-trimethylbenzene in 250 parts of deionized water were heated and stirred at 40° C. for 2 hours until it was completely dissolved to obtain a clear solution A.

[0035] 2) Add 90 parts of ferrous gluconate to the above-mentioned clear solution A, heat and stir at 30° C. for 1 hour, and wait until it dissolves completely to obtain clear solution B.

[0036] 3) Put the above-mentioned clear solution B in a reactor, then place the reactor in an oven with a temperature of 160° C. for a heating reaction for 16 hours, and wash the obtained intermediate product three times with water and alcohol.

[0037] 4) The above intermediate product was carbonized in an argon atmosphere, the carbonization temperature was 900° C., and the carbonization time was 2 hours, to obtain the iron oxide-mesoporous carbon lithium ion battery negati...

Embodiment 3

[0039] 1) 55 parts of resorcinol, 35 parts of urotropine, 100 parts of polyoxyethylene-polyoxypropylene-polyoxyethylene triblock copolymer Pluronic F-127 (PEO 106 -PPO 70 -PEO106 ) and 21 parts of 1,3,5-trimethylbenzene were dissolved in 220 parts of deionized water, heated and stirred at 30°C for 2 hours, until they were completely dissolved, and a clear solution A was obtained.

[0040] 2) Add 80 parts of ferrous gluconate to the above-mentioned clear solution A, heat and stir at 30° C. for 1 hour, and wait until it dissolves completely to obtain clear solution B.

[0041] 3) Put the above-mentioned clear solution B in a reaction kettle, then place the reaction kettle in an oven at a temperature of 100° C. for heating and reacting for 12 hours, and wash the obtained intermediate product 3 times with water and alcohol.

[0042] 4) The above intermediate product was carbonized in an argon atmosphere, the carbonization temperature was 700° C., and the carbonization time was 5 ...

PUM

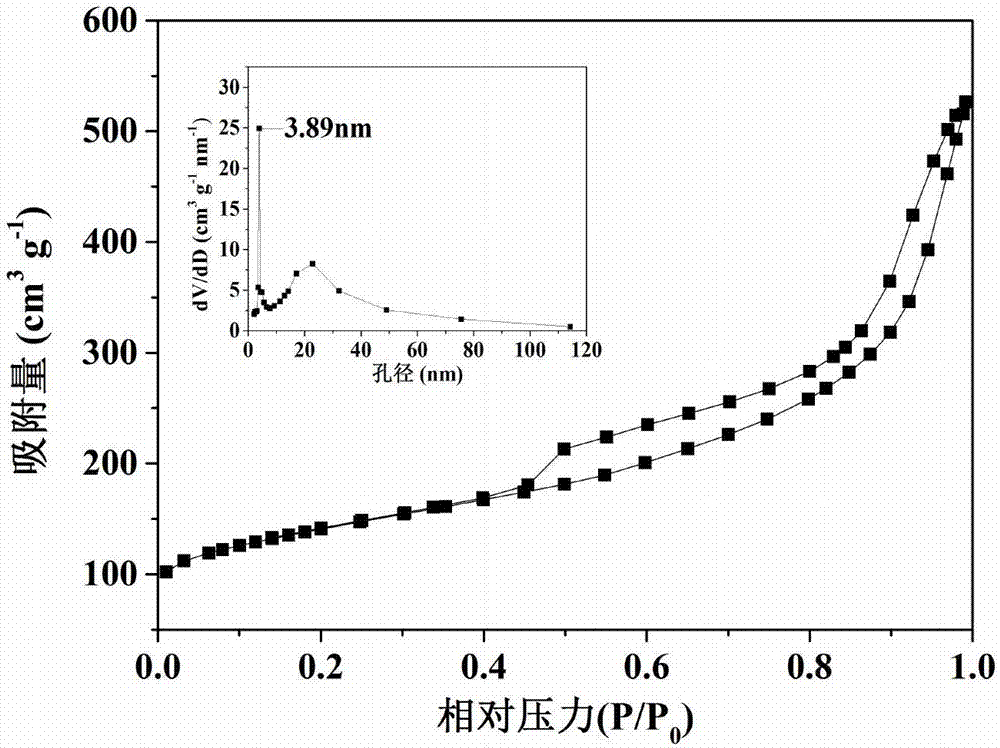

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com