Nitrogen and phosphor-doped biomass carbon material synthetic method and application of biomass carbon material in microbiological fuel cell cathode

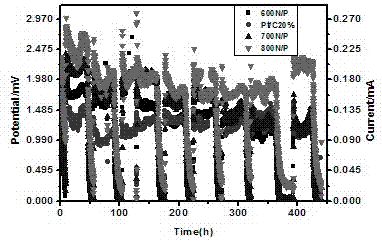

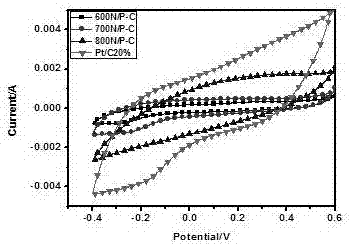

A biomass carbon and synthetic method technology, applied in biochemical fuel cells, battery electrodes, circuits, etc., can solve the problems of slow electron kinetic transfer rate, hinder widespread commercialization, and high price, and achieve good microbial cathode oxygen reduction catalysis. Activation, reduction of cathodic activation overpotential, and the effect of increasing power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0029] 1. The generation of biomass carbon materials;

[0030] (1) Pretreatment of biomass: honeycomb is used as carbon source, at 500mg / L Na 2 CO 3 Soak in the solution for 1 hour, filter with suction, rinse with deionized water, and vacuum dry at 60°C for 12 hours, set aside.

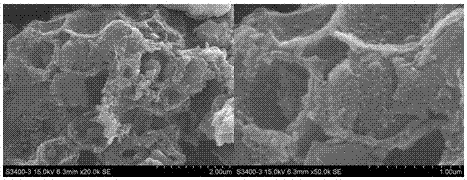

[0031] (2) The production of biomass carbon materials: the pretreated biomass is put into a porcelain bowl, calcined in a tube furnace, and argon is introduced. The temperature is raised from room temperature to 600°C and 700°C at 3°C / min. There are three different temperatures of ℃ and 800℃, which are kept for 5h at each maximum temperature. Naturally cool to room temperature. It is fired at three different temperatures to obtain biomass carbon materials fired at three different temperatures. After taking it out, it is a black solid, grind and set aside.

[0032] 2. Synthesis of N / P-C composite materials doped with nitrogen and phosphorus heteroatoms;

[0033] (1) Oxidation of biomass carbon material: The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com