A kind of low toxicity wood preservative and preparation method thereof

A wood preservative, low toxicity technology, applied in wood impregnation, wood treatment, impregnated wood and other directions, can solve problems such as unreported, and achieve the effect of wide source, uniform color, good color and luster

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

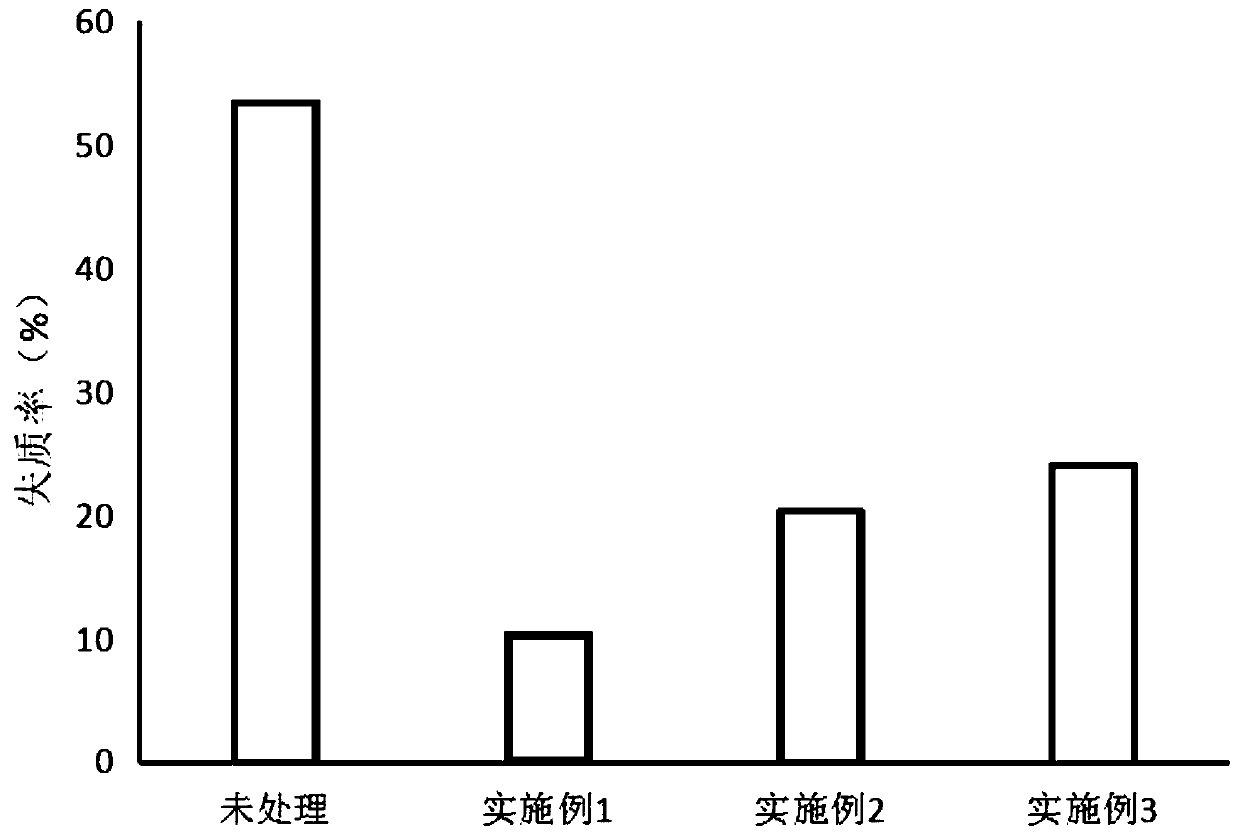

Examples

Embodiment 1

[0027] 4 parts of copper sulfate, 5 parts of borax, and 18 parts of poultry feather protein pyrolysis solution are used. The preparation method of the pyrolysis liquid is as follows: pretreatment with sodium sulfite after washing fresh chicken feathers, the pretreatment time is 16h, then carry out pyrolysis in a sodium hydroxide (NaOH) solution with a concentration of 8%, after the pretreatment, the feathers and The weight part of sodium hydroxide solution is 1:4, the pyrolysis temperature is 150°C, and the pyrolysis time is 6h, and then a pyrolysis solution is formed; copper sulfate and borax are measured according to the formula ratio, and after mixing at 25°C Dissolve together in water, and fully dissolve to obtain a blue suspension of copper sulfate and borax, then add poultry feather protein pyrolysis solution and stir at the same time to form a brown turbid solution, that is, the low-toxicity wood preservative is obtained.

[0028] In the present invention, after the pre...

Embodiment 2

[0030] Adopt 7 parts of copper sulfate, 5 parts of borax, and 20 parts of pyrolysis solution; the preparation method of pyrolysis solution is: pretreat with sodium sulfite after washing the fresh feathers and duck feathers, the pretreatment time is 30h, and then in the concentration of 6% Carry out pyrolysis in sodium hydroxide (NaOH) solution, the weight portion of feather and sodium hydroxide solution after pretreatment is 1:6, and pyrolysis temperature is 160 ℃, and pyrolysis time is 8h, then forms pyrolysis liquid; Take copper sulfate and borax according to the above formula ratio, and dissolve them in water together at 30°C. After fully dissolving, a blue suspension of copper sulfate and borax is obtained, and then add poultry feather protein pyrolysis solution and stir at the same time to form a brown color. Cloudy liquid, promptly obtains described low toxicity wood preservative.

[0031] In the present invention, after the preparation of the pyrolysis solution is compl...

Embodiment 3

[0033] Use 5 parts of copper sulfate, 8 parts of borax, and 5 parts of pyrolysis solution; the preparation method of pyrolysis solution is: wash the fresh feathers and goose feathers and pretreat them with sodium sulfite, the pretreatment time is 28h, and then add hydrogen at a concentration of 7%. Carry out pyrolysis in sodium oxide (NaOH) solution, the weight portion of feather and sodium hydroxide solution after pretreatment is 1:8, and pyrolysis temperature is 140 ℃, and pyrolysis time is 4h, then forms pyrolysis liquid; Measure copper sulfate and borax at 25°C, mix them and dissolve them together in water. After fully dissolving, a blue suspension of copper sulfate and borax is obtained. Then add poultry feather protein pyrolysis solution and stir at the same time to form brown turbidity. liquid, that is, to obtain the low toxicity wood preservative.

[0034] In the present invention, after the preparation of the pyrolysis solution is completed, hydrochloric acid or aceti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com