Method for repairing arsenic-containing wastewater by using sludge

A sludge and wastewater technology, applied in water/sludge/sewage treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems of limited arsenic adsorption efficiency, waste of resources, increased cost, etc. The effect of efficient utilization and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The method for using sludge to repair arsenic-containing wastewater involved in this embodiment specifically includes the following steps:

[0026] (2) Pre-cultivation of sludge

[0027] Select 200-500 parts of urban sewage field sludge, industrial organic sludge or anaerobic digestion sludge according to parts by weight, add 70 parts by weight of ferrous sulfate and 40 parts of potassium nitrate, put them into the incubator and mix them, and fill with nitrogen for 20 -60 minutes, control the temperature at 20-30°C for static culture for 7-10 days to prepare pre-cultured sludge for later use;

[0028] (2) Preparation of NAFO medium

[0029] Add the medium into the bioreactor according to the following weight ratio: NH 4 Cl 25-30 parts, K 2 HPO 4 20-30 parts, MgSO 4 10-15 parts, CaCl 2 1-3 parts, 80-410 parts of anhydrous sodium acetate, 80-170 parts of sodium nitrate or 100-210 parts of potassium nitrate, FeCl 2 4H 2 O200-400 parts or heptahydrate FeSO 4 27...

Embodiment 2

[0037]The sludge was obtained from a sewage treatment plant in Jimo City, Qingdao. It was digested sludge. 200 mL of sludge was added with 0.71 g of ferrous sulfate and 0.4 g of potassium nitrate, filled with nitrogen for 30 min, and incubated at 25 °C for 7 days. Take 10mL sample from the above preculture sludge and add to 200mL sterile NAFO medium: NH 4 Cl 0.28g / L, K 2 HPO 4 0.25g / L, MgSO 4 0.1g / L, CaCl 2 0.01g / L, sodium acetate 20mM, sodium nitrate 15mM, FeCl 2 4H 2 O 15mM, adjust the pH to 7.0. Nitrogen gas was filled into the reactor for 30 minutes, and the culture was statically cultivated at 25°C for 8 days. After culturing, the sludge turns from black to yellow-brown, and the bio-iron flocculant is obtained.

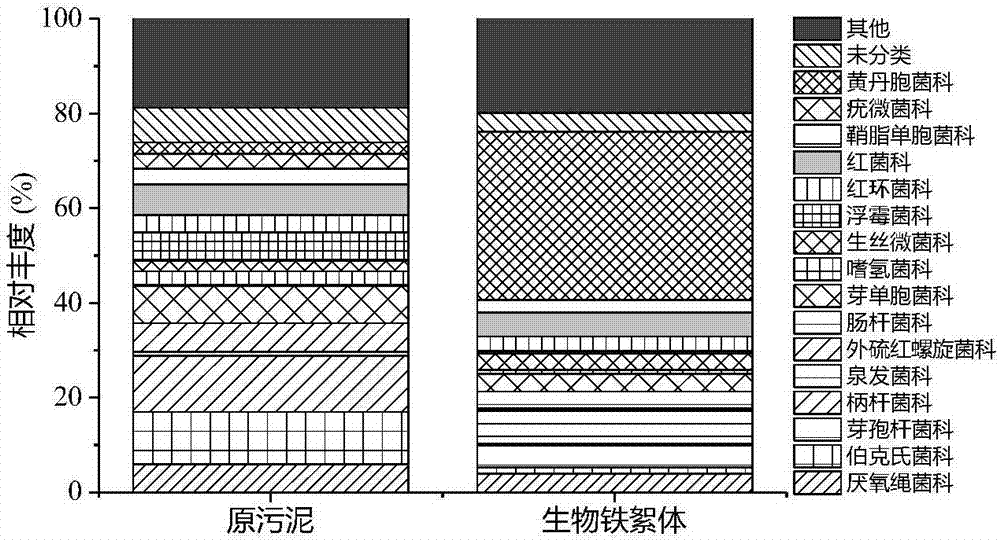

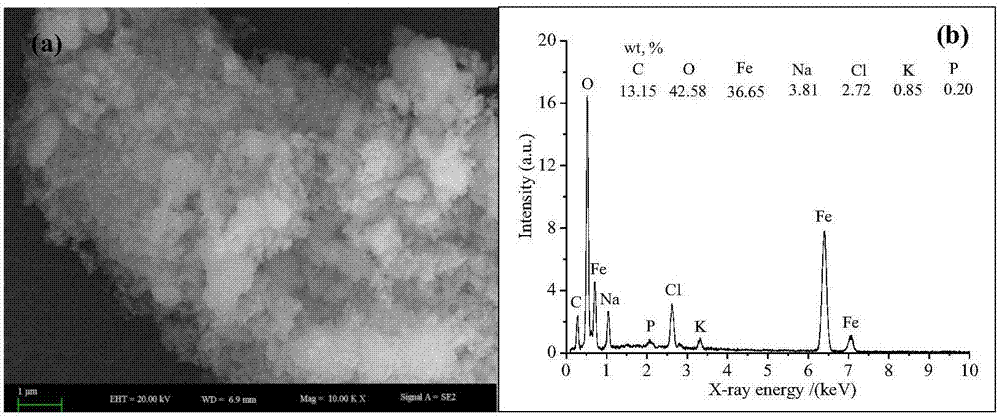

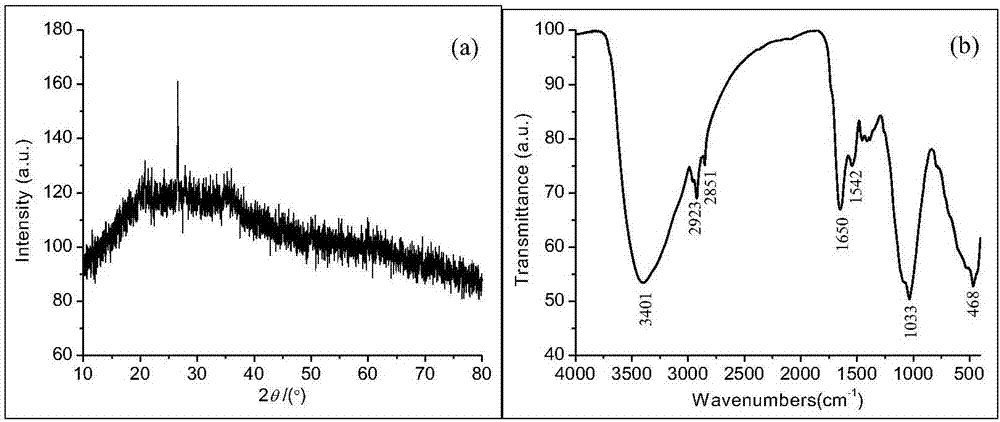

[0038] After NAFO culture, the apparent color of the sludge changed significantly, from the initial black with stench to yellow-brown flocs, and the odor disappeared; high-throughput 16s rRNA gene sequencing was used to construct the microbial community ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com