Preparation method of 2,2-difluoro-1,3-propanediol

A technology of difluoropropanol and propylene glycol, which is applied in the field of preparation of 2,2-difluoro-1,3-propanediol, can solve the problems of high synthesis cost, limited practical application, and difficulty in obtaining raw materials, and achieves good stability, Simple equipment requirements and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

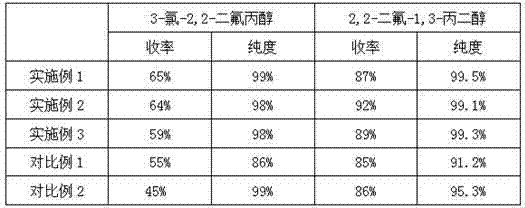

Examples

Embodiment 1

[0024] 1.1 Preparation of 2-chloro-1,1-difluoroethylene

[0025] Add 1200g of 30% sodium hydroxide aqueous solution and 2.5g of tetrabutylammonium bromide into a 2000ml three-necked flask, and add 500g of 1,2-dichloro-1,1-difluoroethane while stirring with a dropping funnel, React at 30°C for 6h, then pass the gas through the condenser tube into the collection bottle of carbon tetrachloride, and the collection bottle is cooled to minus 20°C by dry ice. The weight of the collection bottle increased by about 300g; the purity of the reaction gas 2-chloro-1,1-difluoroethylene detected by gas chromatography was 98%;

[0026] 1.2 Preparation of 3-chloro-2,2-difluoropropanol

[0027] The 3L reaction kettle was condensed and cooled by the coil, vacuumized, and 500g of carbon tetrachloride solution of 2-chloro-1,1-difluoroethylene with a mass concentration of 22.6% in the cold well was sucked into the kettle, which contained 2-chloro- Add 113g of 1,1-difluoroethylene, add 1101g of me...

Embodiment 2

[0031] 2.1 Preparation of 2-chloro-1,1-difluoroethylene

[0032] In a 2000ml three-necked flask, add 1166g of 30% aqueous sodium hydroxide solution, 5g of tetrabutylammonium bromide, and add 1,2-dichloro-1,1-difluoroethane 500g while stirring with a dropping funnel, in React at 30°C for 6 hours, then pass the gas through the condenser tube into the collection bottle with 1 kg of carbon tetrachloride remaining, and cool the collection bottle to minus 25°C with dry ice. The weight of the collection bottle increased by about 300g; the purity of the reaction gas 2-chloro-1,1-difluoroethylene detected by gas chromatography was 99%;

[0033] 2.2 Preparation of 3-chloro-2,2-difluoropropanol

[0034] The 3L reaction kettle was condensed and cooled by the coil, vacuumized, and 500g of carbon tetrachloride solution of 2-chloro-1,1-difluoroethylene with a mass concentration of 22.6% in the cold well was sucked into the kettle, which contained 2-chloro- Add 113g of 1,1-difluoroethylene,...

Embodiment 3

[0038] 3.1 Preparation of 2-chloro-1,1-difluoroethylene

[0039] Add 1200g of 30% sodium hydroxide aqueous solution and 3.8g of tetrabutylammonium bromide into a 2000ml three-necked flask, and add 500g of 1,2-dichloro-1,1-difluoroethane while stirring with a dropping funnel, React at 30°C for 6h, then pass the gas through the condenser tube into the collecting bottle with 1kg of carbon tetrachloride remaining, and the collecting bottle is cooled to minus 25°C by dry ice. The weight of the collection bottle increased by about 300g; the purity of the reaction gas 2-chloro-1,1-difluoroethylene detected by gas chromatography was 98%;

[0040] 3.2 Preparation of 3-chloro-2,2-difluoropropanol

[0041] The 3L reaction kettle was condensed and cooled by the coil, vacuumized, and 500g of carbon tetrachloride solution of 2-chloro-1,1-difluoroethylene with a mass concentration of 22.6% in the cold well was sucked into the kettle, which contained 2-chloro- Add 113g of 1,1-difluoroethyle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com