Hexagonal boron nitride nanosheet and preparation method thereof

A technology of hexagonal boron nitride and nanosheets, applied in chemical instruments and methods, catalyst activation/preparation, nanotechnology, etc., can solve the problems of not using the properties of h-BN itself, high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1) h-BN powder pretreatment

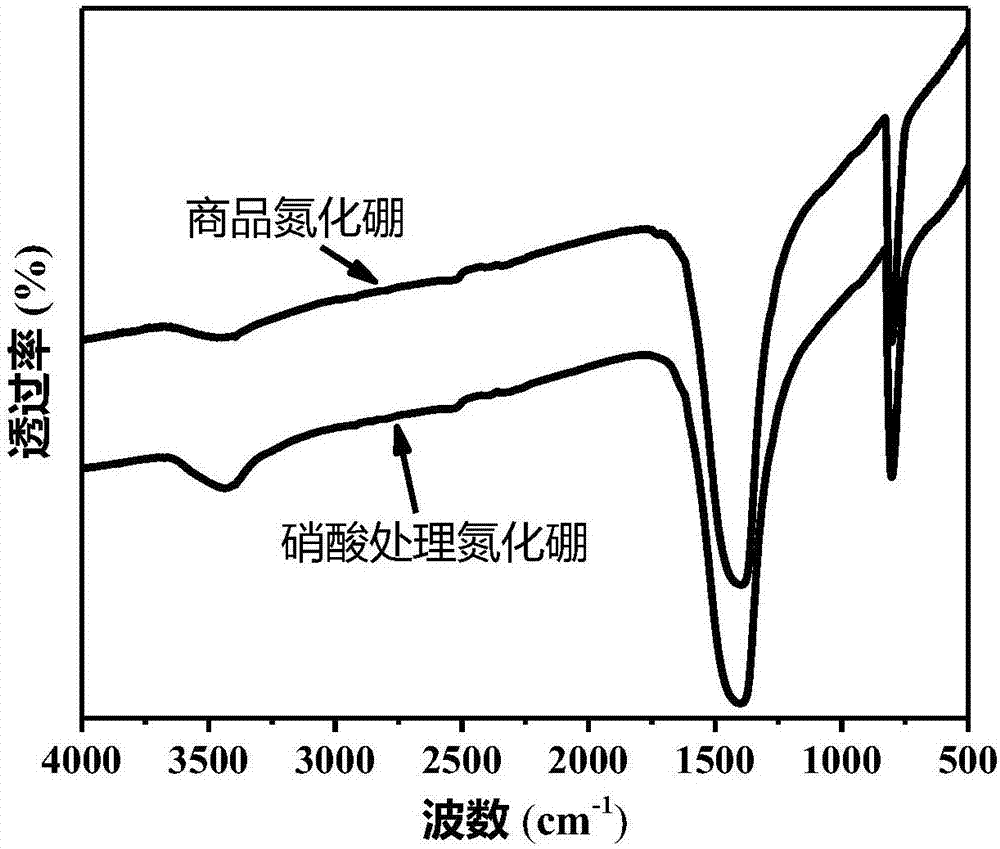

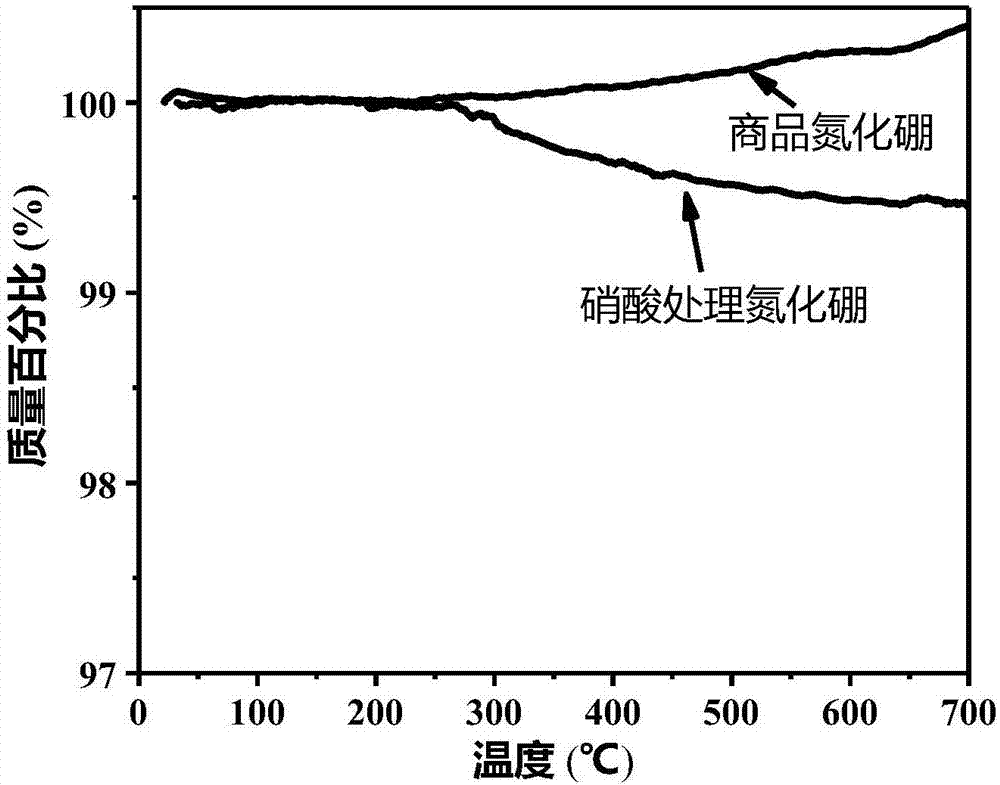

[0041] Weigh 2g of commercial h-BN powder into a 250mL round bottom flask, add 80mL of 10% nitric acid solution (65% nitric acid: water = 1:5.5 (v / v)) to it, and put a stirring magnet. Place the round-bottomed flask in an oil bath, start magnetic stirring, heat to 80°C, keep it for 5h, then cool to room temperature naturally. The dispersion was placed in a high-speed centrifuge (HC-2518), and the BN particles were centrifuged at a speed of 8000 rpm, and rinsed with deionized water until the washing liquid was neutral. The treated product was dried in a 50°C electric blast oven (GZX-9070MBE) for 24h. FT-IR spectra of BN powder before and after pretreatment as figure 1 as shown, figure 1 It is the infrared spectrum of h-BN before and after nitric acid treatment in the embodiment of the present invention 1, by figure 1 It can be seen that there is basically no difference between the two, 1395cm -1 The absorption peak is attributed to the ...

Embodiment 2

[0046] 1) See Example 1 for the pretreatment of h-BN powder.

[0047] 2) Radiation stripping of BNNS

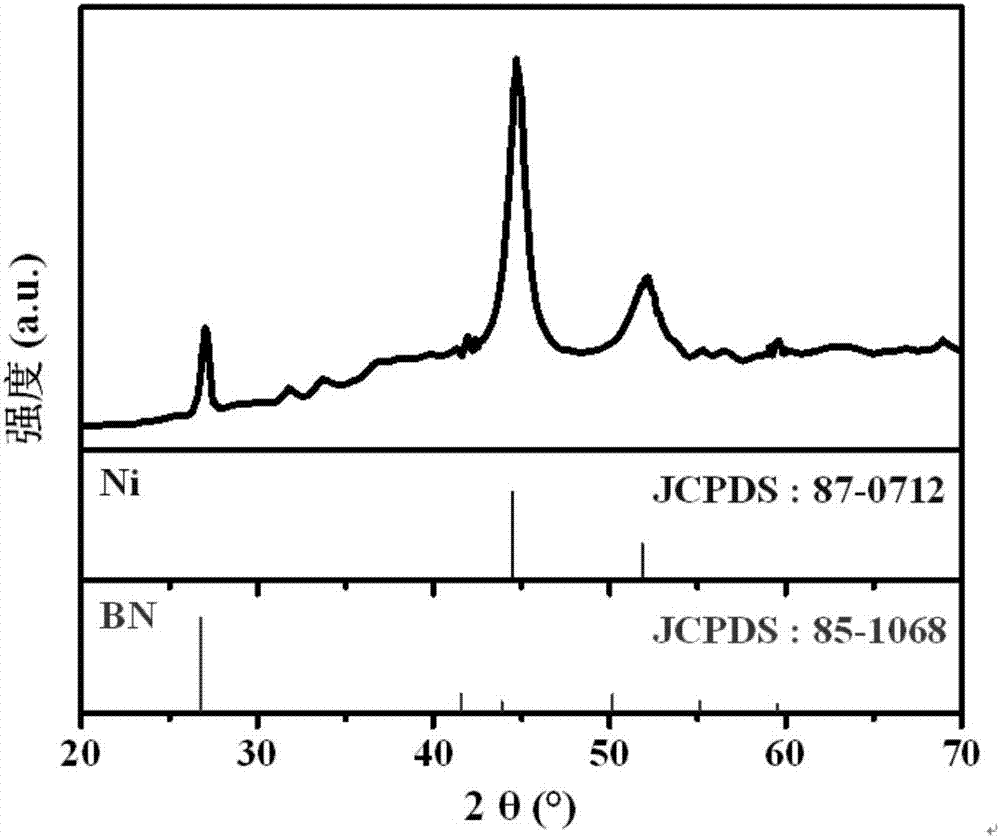

[0048] Weigh 20 mg of h-BN powder treated with nitric acid, and ultrasonically disperse it in 42.5 mL of deionized water. Add 7.5mL of isopropanol (IPA) and 1.188g of nickel chloride hexahydrate into the h-BN dispersion in sequence, and put in a stirring magnet. The round bottom flask was placed in a constant temperature heating magnetic stirrer (DF-101K), heated to 70°C and kept for 3d. After heating, measure 25mL of the above dispersion liquid into the dropping funnel, drop it into a flask filled with 25mL of 8g / L CTAC aqueous solution, and disperse evenly by ultrasonic. Then put into the stirring magnet, seal with Parafilm sealing film after passing nitrogen for 10min, and fix the flask in the cobalt source chamber with an iron stand, irradiate for 48h under magnetic stirring, and the absorbed dose rate is 92.1Gy / min (ferrous sulfate dose meter calibration), the total a...

Embodiment 3

[0051]Weigh 20 mg of commercial h-BN powder, and ultrasonically disperse it in 42.5 mL of deionized water. Add 7.5mL of isopropanol (IPA) and 1.188g of nickel chloride hexahydrate into the h-BN dispersion in sequence, and put in a stirring magnet. The round bottom flask was placed in a constant temperature heating magnetic stirrer (DF-101K), heated to 70°C and kept for 3d. After heating, measure 25mL of the above dispersion liquid into the dropping funnel, drop it into a flask filled with 25mL 8g / L cetyltrimethylammonium chloride (CTAC) aqueous solution, and disperse evenly by ultrasonic. Then put into the stirring magnet, seal with Parafilm sealing film after passing nitrogen for 10min, and fix the flask in the cobalt source chamber with an iron stand, and irradiate for 48h under magnetic stirring, and the absorbed dose rate is 91.1Gy / min (ferrous sulfate dose meter calibration), the total absorbed dose was 262.4kGy. After the irradiation is over, put the dispersion in a hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com