Energy-saving and clean production method of fuel ethanol

A technology for fuel ethanol and cleaner production, which is applied in the fields of biofuels, climate sustainability, fermentation, etc., and can solve the problems of high discharge of process wastewater, difficulty in achieving cleaner production, and unstable acidity indicators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

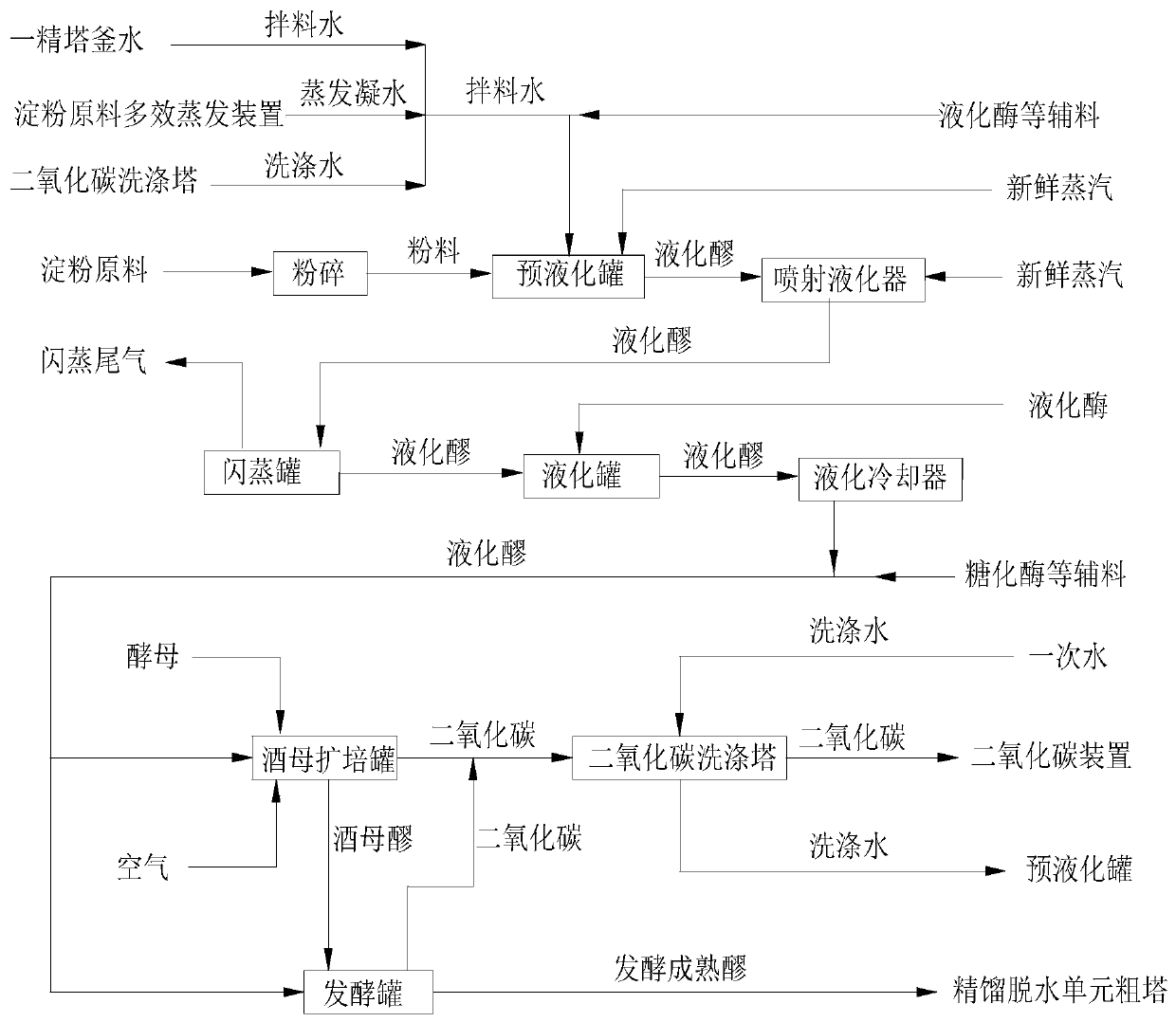

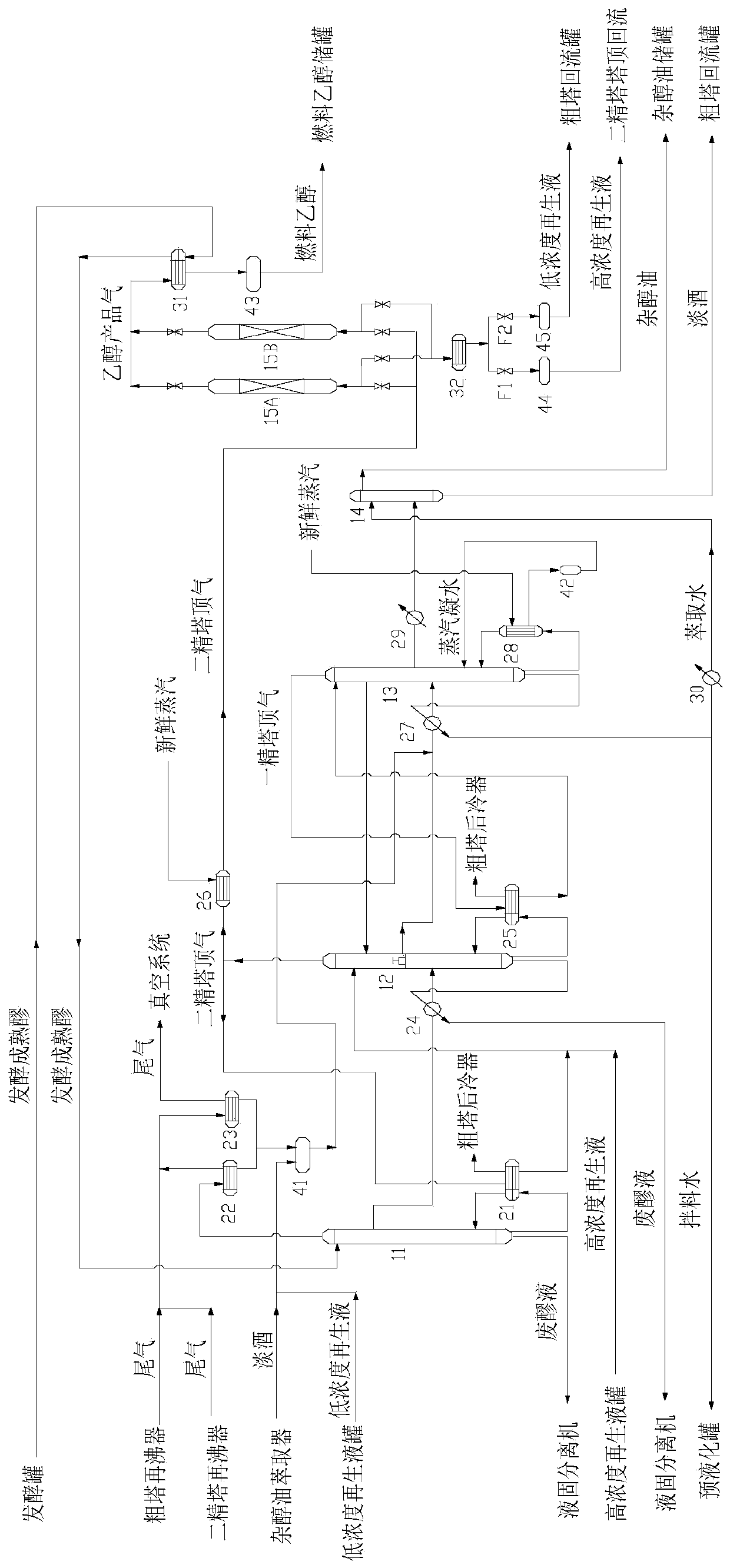

[0097] Using cassava as raw material to produce denatured fuel ethanol products that meet GB 18350-2013, the production process includes mash preparation unit, rectification dehydration unit, and waste mash treatment unit, see e.g. figure 1 , image 3 , Figure 4 . Specific steps are as follows:

[0098] 1. Mash preparation unit

[0099] First, the cassava raw material is sent to a pulverizer for crushing, and the crushed powder is sent to the pre-liquefaction tank, and at the same time, the mixing water is added to the pre-liquefaction tank, and the mixing water includes the evaporative condensation of the multi-effect evaporator of the waste mash processing unit. Water, the water in the first refining tower and the washing water of the carbon dioxide scrubber, and auxiliary materials such as amylase are added to the flow, and the temperature of the mixing material in the pre-liquefaction tank is controlled by introducing fresh steam.

[0100] The liquefied mash in the pr...

Embodiment 2

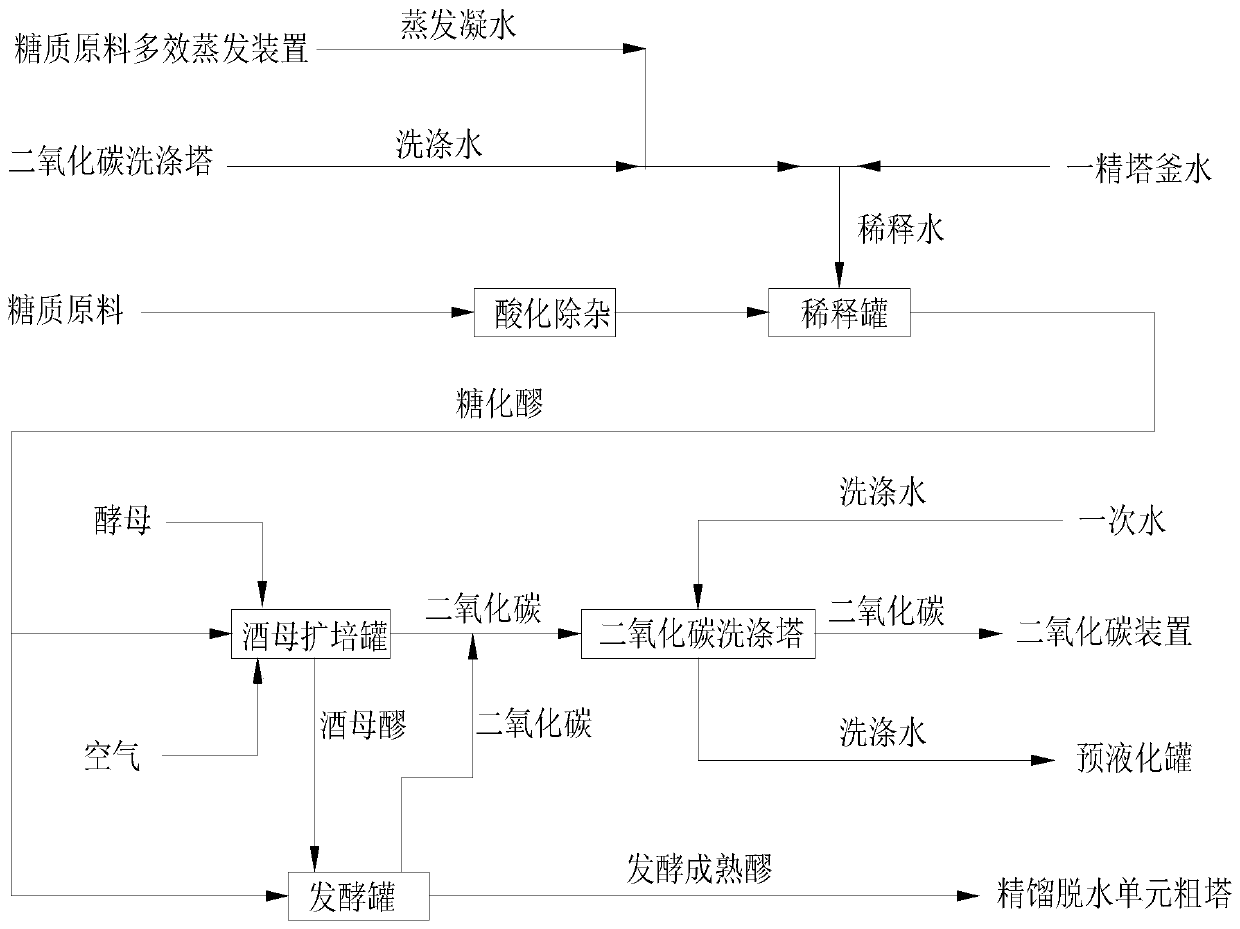

[0117] Using molasses as a raw material to produce denatured fuel ethanol products that meet GB 18350-2013, the production process includes a mash preparation unit, a rectification dehydration unit, and a waste mash treatment unit, see e.g. figure 2 , image 3 , Figure 5 . Specific steps are as follows:

[0118] 1. Mash preparation unit

[0119] For sugary raw materials, after acidification, impurity removal and dilution, the saccharification mash is directly obtained, and part of the saccharification mash is directly sent to the distiller's expansion tank, and part is sent to the fermentation tank. Water, the water in the first rectifying tower kettle of the rectification dehydration unit and the washing water in the tower kettle of the carbon dioxide scrubber.

[0120] The yeast is also sent to the expansion tank, and an appropriate amount of sterile air is continuously introduced into the tank, and the cultivation is carried out at the expansion temperature of 28°C. A...

Embodiment 3

[0135] Using corn as raw material to produce denatured fuel ethanol products meeting GB 18350-2013, the production process includes mash preparation unit, rectification dehydration unit, waste mash treatment unit, see for example figure 1 , image 3 , Figure 4 . Specific steps are as follows:

[0136] 1. Mash preparation unit

[0137]First, the corn is sent to the pulverizer for crushing, and the crushed powder is sent to the pre-liquefaction tank, and at the same time, the mixing water is added to the pre-liquefaction tank. The water in the refining tower and the washing water of the carbon dioxide scrubber, and auxiliary materials such as amylase are added, and the temperature of the mixing material in the pre-liquefaction tank is controlled by introducing fresh steam.

[0138] The liquefied mash in the pre-liquefaction tank is mechanically pumped to the jet liquefier, and the jet liquefier controls the temperature of the material at the outlet of the injector by contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com