Barium titanate particles, barium titanate/fluorine-containing polymer composite material, and preparation methods of barium titanate particles and barium titanate/fluorine-containing polymer composite material

A technology of composite materials and barium titanate, which is applied in the field of capacitors and energy storage materials, can solve the problems of low dielectric properties and achieve high dielectric properties, good breakdown performance, and improved dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] (1) Preparation of barium titanate particles

[0040] The coral-like barium titanate particles of the present invention can be synthesized by liquid phase methods, such as sol-gel method, co-precipitation method, solvothermal method and hydrothermal method. Preferably, the coral-like barium titanate particles of the present invention are prepared by a hydrothermal method.

[0041] The specific process of preparing coral-like barium titanate by hydrothermal method is as follows: deionized water is used as solvent, tetrabutyl titanate and barium hydroxide are used as titanium source and barium source respectively, and cetyltrimethylammonium bromide is used as additive , at a hydrothermal reaction temperature of 150-200°C and a reaction time of 6-15 hours, coral-like barium titanate particles were prepared.

[0042] The preferred reaction temperature and time ranges of the present invention are 180-200°C and 10-15h. More preferred reaction temperature and time are 180°C ...

Embodiment

[0061] Hereinafter, the present invention will be further described in detail through preferred embodiments.

[0062] For comparison, the spherical barium titanate / polyvinylidene fluoride flexible composite material and the spherical barium titanate / polyvinylidene fluoride flexible composite material modified with titanate coupling agent are also listed as the comparison of the present invention example.

Embodiment 1

[0068] The first step, preparation of coral-like barium titanate particles

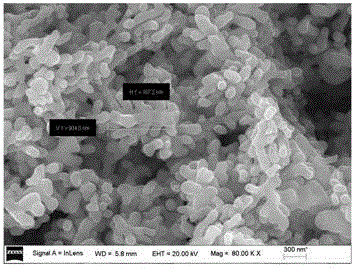

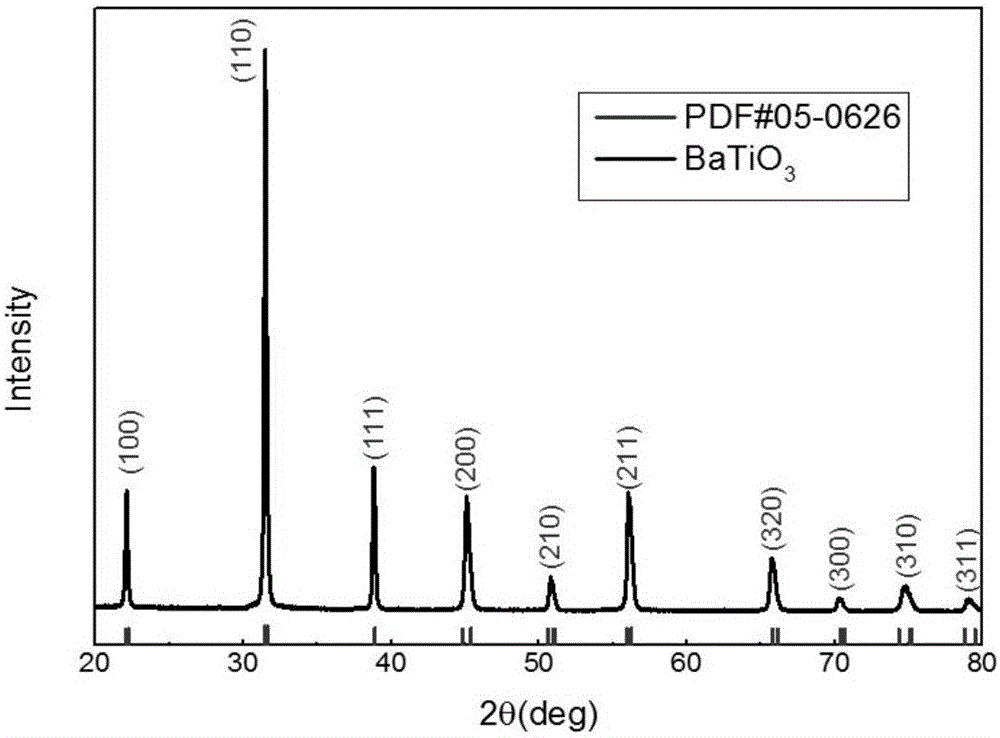

[0069] Take by weighing 0.1g cetyltrimethylammonium bromide (CTAB) and place in 35ml of deionized water, after fully stirring and dissolving, 2.0g barium hydroxide (Ba(OH) 2 ·8H 2 O) placed in the above solution, fully mixed to form a suspension, then 2ml of tetrabutyl titanate was added to the above suspension and continued to stir for 10 minutes to obtain about 38ml of barium titanate precursor suspension, which was transferred to 100ml In a hydrothermal kettle with a polytetrafluoroethylene lining, seal it, screw it tightly, and place it in an oven at 180°C for hydrothermal reaction for 12 hours, then take the hydrothermal kettle out of the oven and cool it to room temperature, add 30ml of deionized After washing and filtering, the mixture was washed and filtered several times, and dried in a drying oven at 50°C for 7 hours to obtain a white powder. Take a small amount of dried powder for scannin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The maximum diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com