Pulse laser emission circuit

A technology of transmitting circuit and pulsed laser, applied in the field of laser measurement, can solve the problems of large ripple, unadjustable high voltage, unstable voltage, etc., and achieve the effects of small parasitic parameters, strong stability, and reduced power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

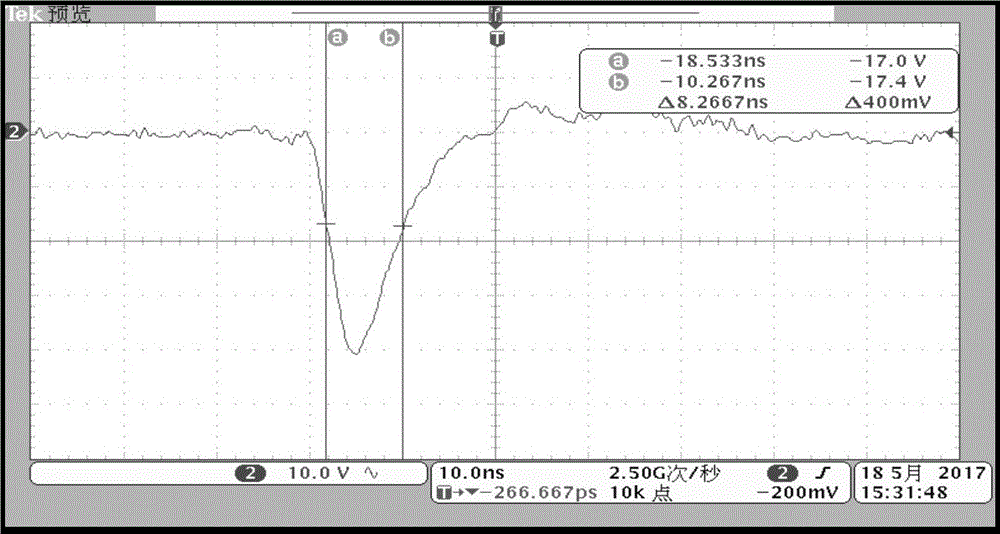

Image

Examples

Embodiment Construction

[0016] It is easy to understand that, according to the technical solution of the present invention, those skilled in the art can imagine various implementations of the pulsed laser emitting circuit of the present invention without changing the essence of the present invention. Therefore, the following specific embodiments and drawings are only exemplary descriptions of the technical solution of the present invention, and should not be regarded as the entirety of the present invention or as a limitation or limitation on the technical solution of the present invention.

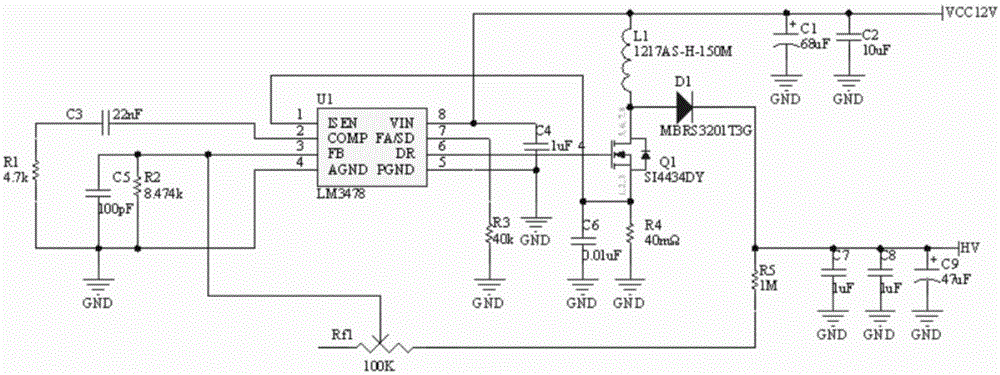

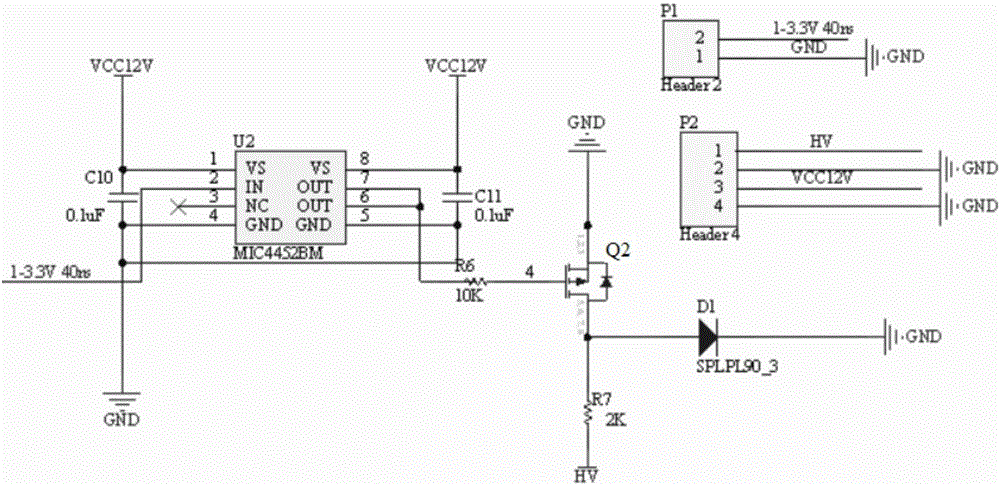

[0017] combine figure 1 , the high voltage generating circuit of the laser diode SPLPL90_3 includes a boost controller U1LM3478, a first resistor R1, a third capacitor C3, a fifth capacitor C5, a second resistor R2, a sliding rheostat Rf1, a third resistor R3, a fourth capacitor C4, a Six capacitors C6, fourth resistor R4, switch MOS chip SI4434DYQ1, first inductor L1, first diode D1, fifth resistor R5, first ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com