Water-based conductive coating and its application before electrostatic spraying of wood products

A conductive coating and electrostatic spraying technology, applied in conductive coatings, coatings, etc., can solve the problems of inability to completely close the pores of wood product substrates, the difficulty of controlling preheating process parameters, and the quality of induced product coating films, and achieve easy preparation. gain, improve electrical conductivity, and reduce pinholes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

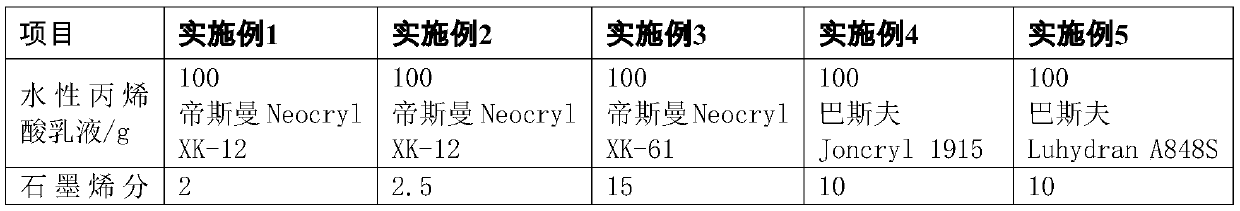

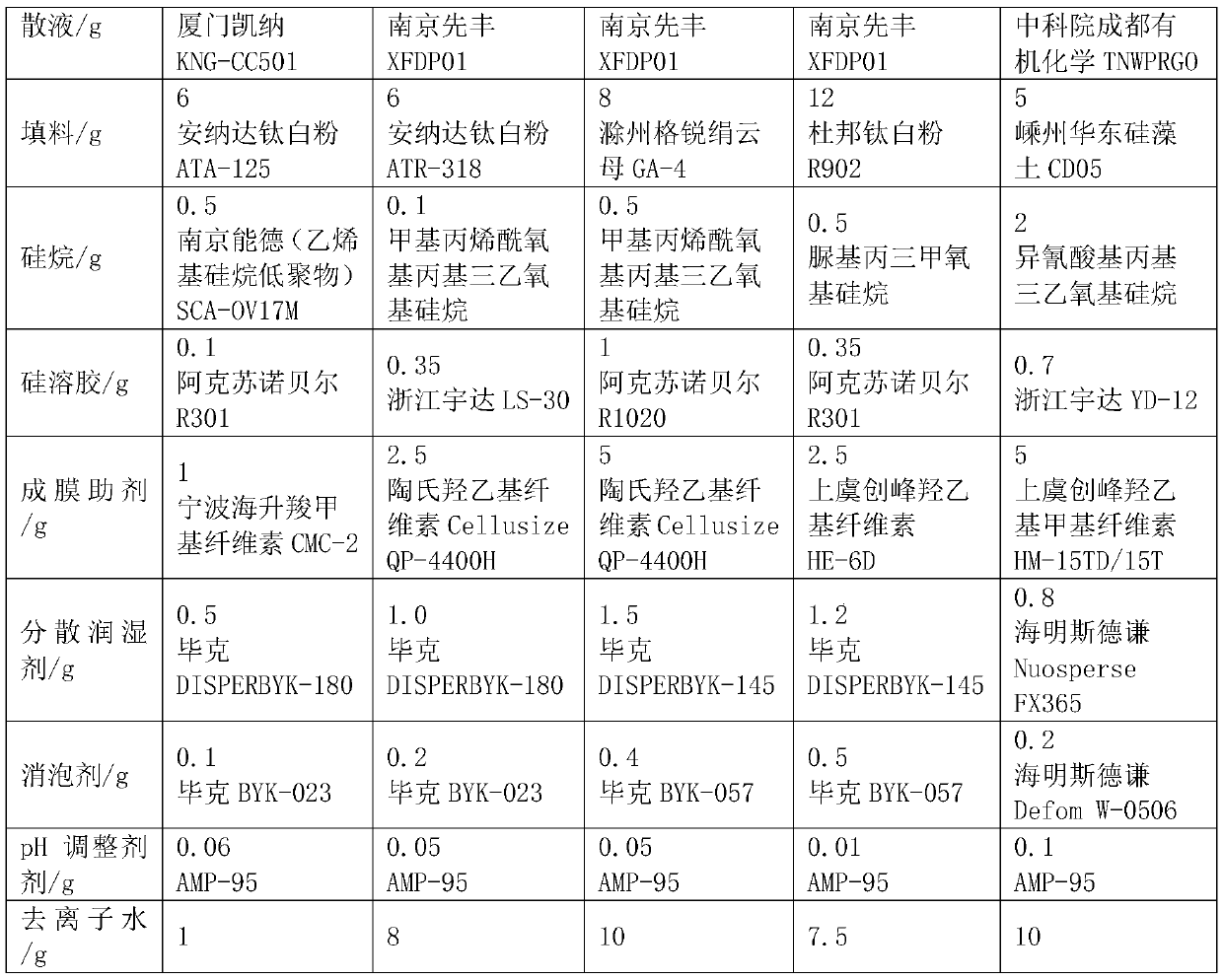

Embodiment 1-5

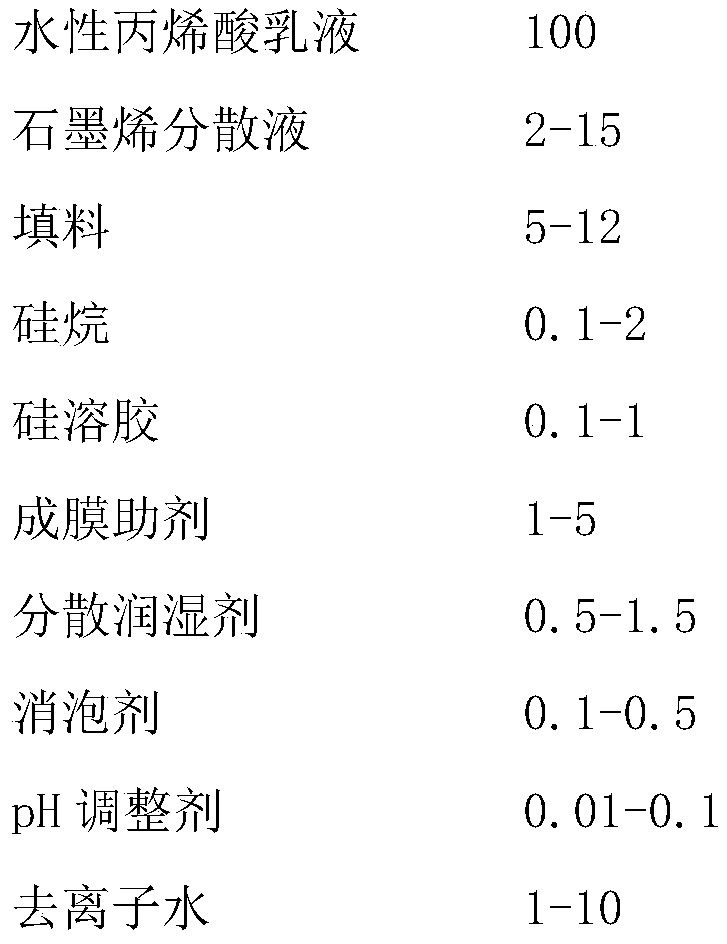

[0029] See Table 1 for the content of each component of the raw materials of the water-based conductive coating before electrostatic spraying of wood products. Its preparation method is:

[0030] 1) Add water-based acrylic emulsion, graphene dispersion, silica sol, and antifoaming agent with half the mass ratio according to the proportion of each component raw material into the mixing tank, and stir at a low speed to form an emulsion mixture;

[0031] 2) Add fillers, silanes, film-forming aids, dispersing wetting agents, pH regulators, deionized water and the remaining defoamers into the mixing tank according to the mass ratio of each component raw material, and perform high-speed dispersion and grinding made into slurry;

[0032] 3) Add the slurry into the emulsion mixture in batches at a slow speed. After the slurry added in the previous batch is uniformly stirred at a low speed, continue to add the slurry in the subsequent batch until the mixing is complete, and the water-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com