Device and method for molten iron ultrasonic treatment on industrial casting site

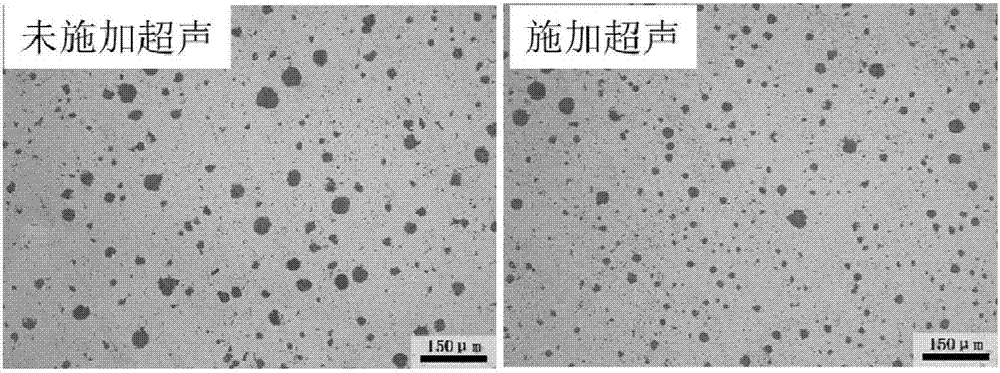

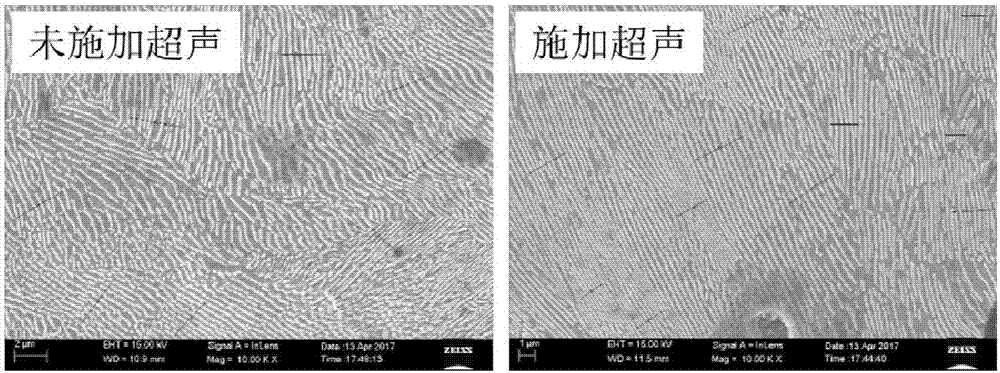

An ultrasonic treatment and ultrasonic technology, applied in the direction of improving process efficiency, etc., can solve problems such as brittle fracture, difficulty in effectively processing metal melts, and ultrasonic power attenuation, so as to improve tissue uniformity, facilitate batch processing, reduce The effect of small lamellar spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

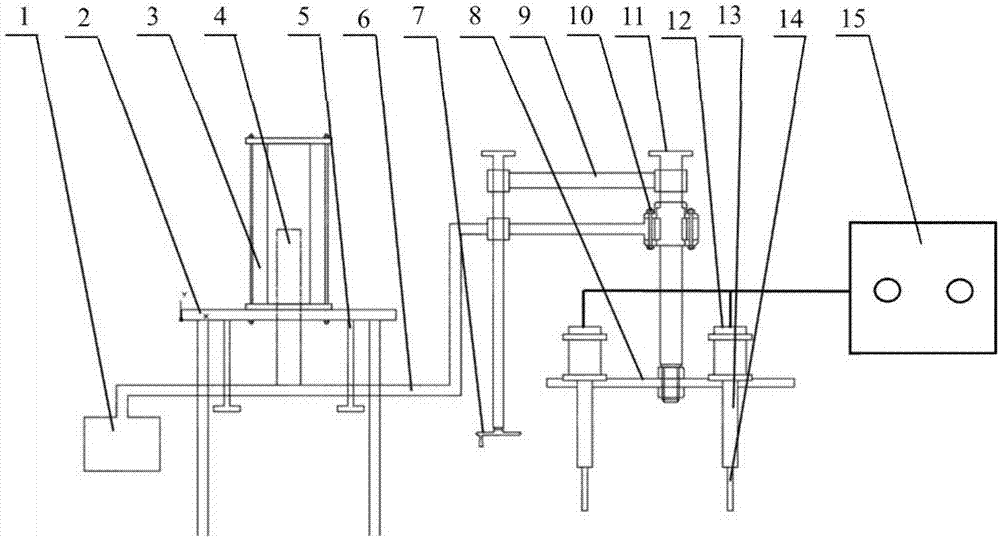

[0039] The device for ultrasonic treatment of molten iron in the industrial foundry site is composed of a smelting device, a spheroidizing ladle, a transfer device, an ultrasonic treatment device and a pouring device. The ultrasonic processing device includes a counterweight 1, a bracket 2, a cylinder 3, a piston rod 4, a distance limiting device 5, a balance bar 6, a hand crank 7, a heat insulating plate 8, a chain transmission device 9, a rolling bearing 10, a rotating rod 11, Ultrasonic transducer 12 , horn 13 , ultrasonic device probe 14 and ultrasonic generator 15 . The cylinder 3 is placed on the top of the bracket 2 and fixed by threaded connection; the cylinder piston rod 4 and the balance rod 6 are connected by welding, and the cylinder piston rod 4 drives the balance rod to move up and down by controlling the cylinder switch; the distance limiting device 5 is welded on Below the top plate of the bracket 2, to control the moving distance of the piston rod 4 and the ba...

Embodiment 2

[0041] S1. Composition ratio: by weight percentage, C: 3.5-3.9%, Si: 1.7-2.1%, Mg: 0.03-0.05%, Cu: 0.2-1.0%, Mn: 0.3-0.6%, S<0.025% , P: <0.06%, Re: 0.012-0.015%, the total content of other impurities ≤0.02-0.05%, the balance is Fe;

[0042] S2. Furnace charge matching: 5% low-P and low-S steel scrap and 10% iron filings, 35% recycle charge, and the rest is high-purity pig iron, according to the composition ratio of step S1 as charge;

[0043] S3. Smelting and refining: Melt the charge in an intermediate frequency induction furnace to obtain molten iron, add industrial ferromanganese, industrial ferrosilicon and electrolytic copper according to the proportion of ingredients in step S1 to evenly smelt, and then release it from the furnace after desulfurization and refining.

[0044] S4. Spheroidizing treatment: select Z6S spheroidizing agent, and the addition ratio is 0.9%, to obtain molten iron after spheroidizing;

[0045] S5. The spheroidization package is transferred to the ...

Embodiment 3

[0054] The difference between the present embodiment and embodiment 2 is only that the process parameters of ultrasonic treatment are different. Ultrasonic device probe 14 stretches into the melt liquid level 500mm in the spheroidizing bag, ultrasonic process parameters: the frequency is 25KHz, the ultrasonic power is 2000W, and the processing time is 25KHz. 1min, the application method is continuous application.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com