Anthocyanin composite nanofiber membrane and preparation method thereof

A composite nanofiber and nanofiber membrane technology, applied in the field of food processing, can solve the problems of extensive size distribution, toxicity and efficacy, poor uniformity, etc., and achieve the effects of stable biological activity, good environmental protection, and improved release uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

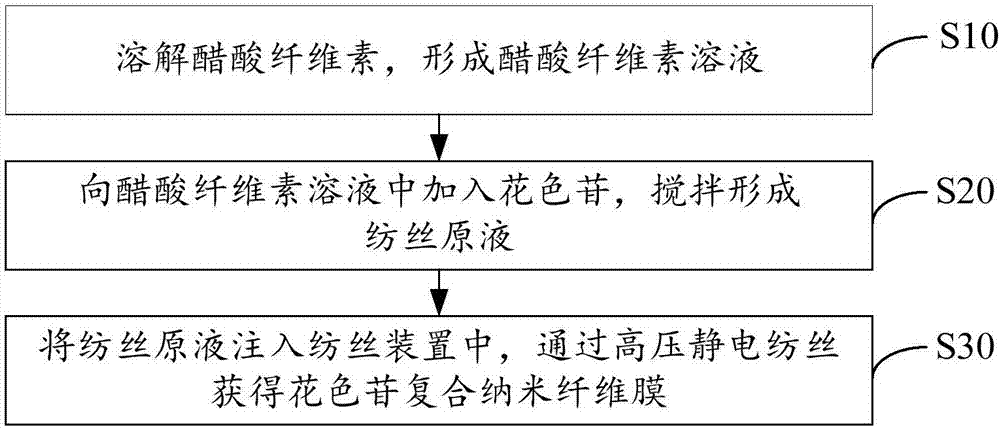

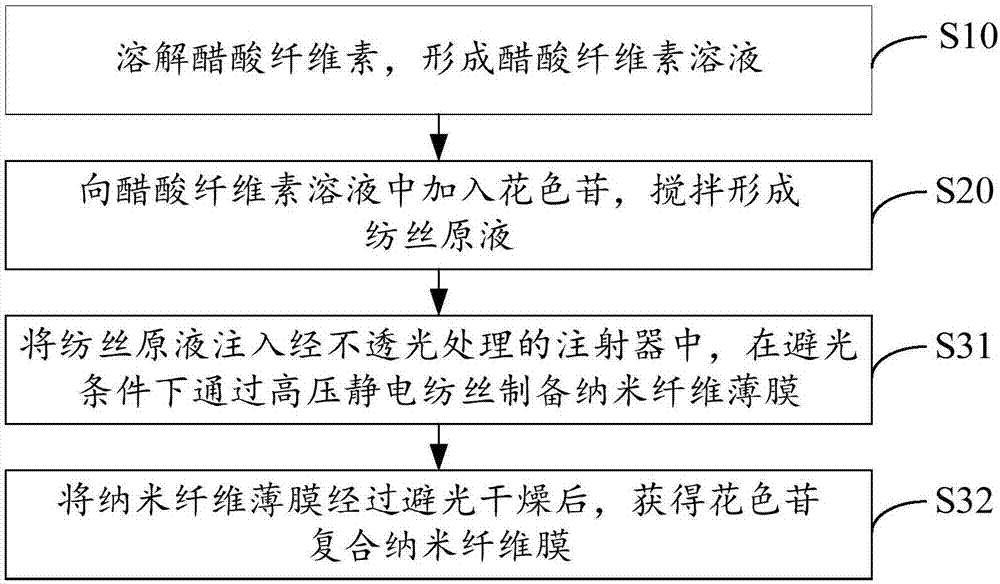

[0038] The present invention also proposes a preparation method of anthocyanin composite nanofiber membrane, please refer to figure 1 , the preparation method of the anthocyanin composite nanofiber film comprises the following steps:

[0039] Step S10, dissolving cellulose acetate to form a cellulose acetate solution;

[0040] Optionally, step S10 includes: stirring a mixture of cellulose acetate and an organic solvent by magnetic force to form a cellulose acetate solution, wherein the organic solvent includes acetone, N-N-dimethylacetamide and anhydrous methanol, wherein the The volume fractions of the acetone, N-N-dimethylacetamide and anhydrous methanol are 30-40%, 30-40% and 30-40% respectively.

[0041] Optionally, the mass of the solvent is 4-8 times that of the cellulose acetate.

[0042] The cellulose acetate is added into a container containing an organic solvent to form a mixture of the cellulose acetate and the organic solvent, and then a cellulose acetate solutio...

Embodiment 1

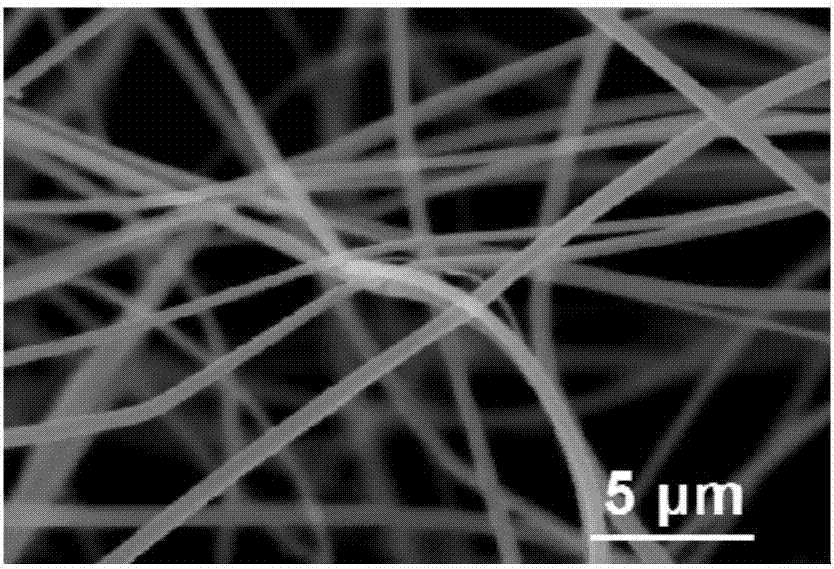

[0060] (1) 1.44g cellulose acetate powder is added in the screw bottle that 9mL solvent (the volume fraction of acetone, DMAc and anhydrous methanol are respectively 35%, 35% and 30%) is housed, stir 2h to Cellulose acetate is completely dissolved to obtain spinning stock solution, wherein the rotating speed of magnetic stirring is 300rpm, and the temperature of magnetic stirring is normal temperature;

[0061] (2) Inject the spinning stock solution into the syringe, control the horizontal distance between the syringe needle and the receiving roller to be 15cm, and prepare the nanofiber membrane by high-voltage electrospinning, wherein the applied voltage of the high-voltage electrospinning is 20kV, and the solution The flow rate is 1.0mL / h;

[0062] (3) The nanofiber membrane was placed in a fume hood at room temperature and protected from light for 24 hours to obtain the cellulose acetate nanofiber membrane.

Embodiment 2

[0064] (1) 1.44g of cellulose acetate powder was added to a screw bottle containing 9mL of solvent (volume fractions of acetone, DMAc and anhydrous methanol were 35%, 35% and 30%, respectively), and stirred for 2h with a magnetic stirrer, Dissolve completely to cellulose acetate, obtain cellulose acetate solution, wherein the rotating speed of magnetic stirring is 300rpm, and the temperature of magnetic stirring is normal temperature;

[0065] (2) Add 43.2 mg of anthocyanin powder to the cellulose acetate solution, and stir for 50 minutes through a magnetic stirrer in the dark until the anthocyanins are completely dissolved to obtain a uniform spinning stock solution, wherein the magnetic stirring speed is 300 rpm, and the magnetic stirring The temperature is normal temperature;

[0066] (3) Inject the spinning stock solution into the syringe, control the horizontal distance between the syringe needle and the receiving roller to be 15cm, and prepare the nanofiber membrane by h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elution gradient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com