A hexagonal columnar cobalt oxyhydroxide material with a hollow structure and its preparation method

The technology of cobalt oxyhydroxide and hexagonal column is applied in the field of hexagonal columnar cobalt oxyhydroxide material and its preparation, which can solve the problem of less research on cobalt oxyhydroxide, and achieve the effects of narrow particle size distribution, simple process flow and mild reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

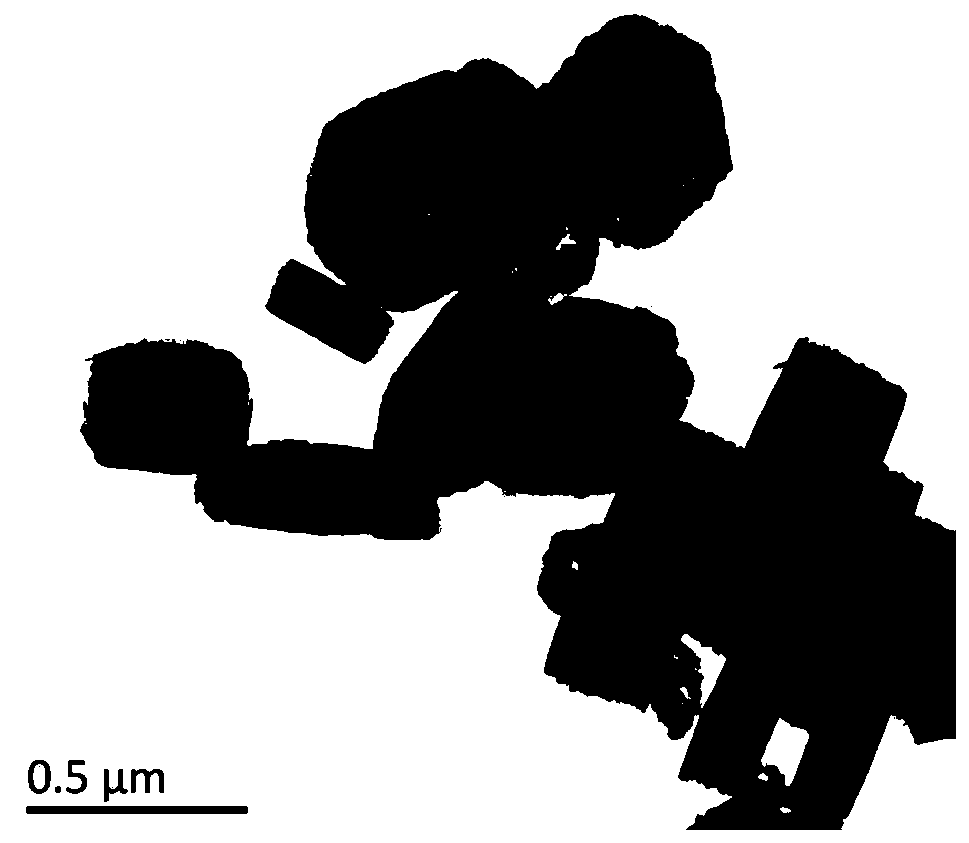

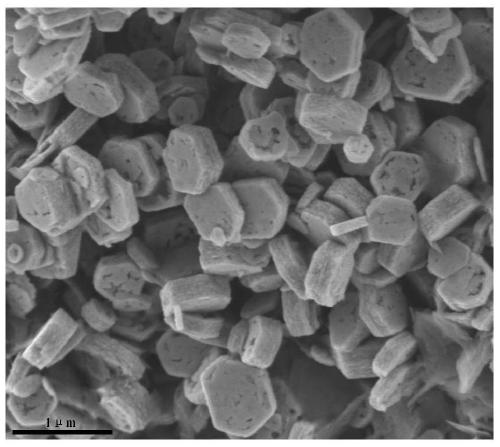

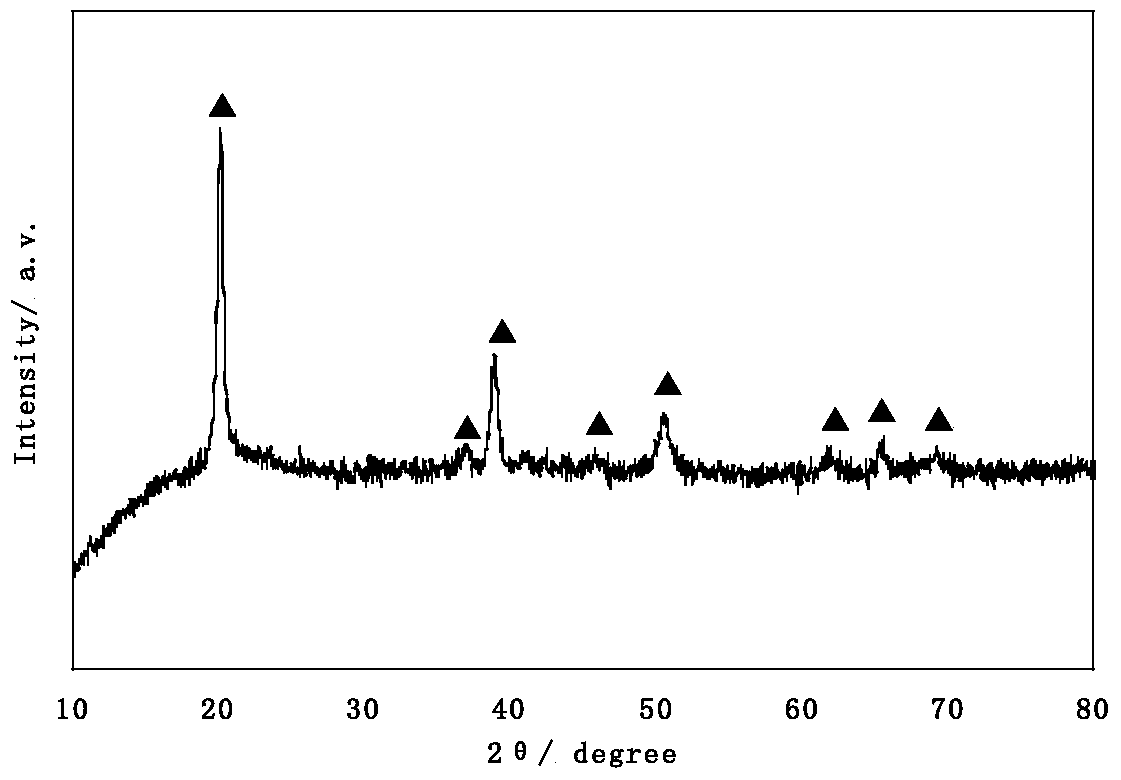

Embodiment 1

[0027] (1) Configure 50 mL of cobalt chloride aqueous solution with a concentration of 0.1 mol / L and 50 mL of ammonia solution with a concentration of 0.2 mol / L; (2) inject the above two solutions into a three-necked flask with the same flow rate (20 mL / min) via a convection pump. In the three-necked flask, nitrogen gas was passed into the three-necked flask in advance, and the reaction was carried out at 50°C and stirring for 30 minutes; (3) 200 mL of NaOH aqueous solution with a concentration of 0.4 mol / L was added, and aged for 30 minutes; (4) The nitrogen gas was removed, and the mass fraction of 10mL of 28% hydrogen peroxide, continue to age for 2h; (5) After the aging is over, the resulting suspension is filtered, washed, and dried (60°C) to prepare a hexagonal columnar cobalt oxyhydroxide with a hollow structure. Its TEM and SEM photos are attached figure 1 and 2 , see attached XRD spectrum image 3 . It can be seen that the length of the six sides of the obtained sa...

Embodiment 2

[0029] (1) Configure 50 mL of cobalt chloride aqueous solution with a concentration of 0.1 mol / L and 50 mL of ammonia solution with a concentration of 0.2 mol / L; (2) inject the above two solutions into a three-necked flask with the same flow rate (20 mL / min) via a convection pump. In the three-necked flask, nitrogen gas was passed into the three-necked flask in advance, and the reaction was carried out at 30°C and stirring for 30 minutes; (3) 200 mL of NaOH aqueous solution with a concentration of 0.4 mol / L was added, and aged for 30 minutes; (4) The nitrogen gas was removed, and the mass fraction of 28% hydrogen peroxide 10ml, continue to age for 2h, (5) after aging, the resulting suspension is filtered, washed, and dried (60°C), to prepare a hexagonal cobalt oxyhydroxide with a hollow structure, the obtained sample The lengths of the six sides are the same or different, all of which are 200-500nm, the longitudinal thickness is 150-200nm, and the volume of the middle cavity is...

Embodiment 3

[0031] (1) Prepare 50 mL of cobalt sulfate aqueous solution with a concentration of 0.1 mol / L and 50 mL of ammonia solution with a concentration of 0.2 mol / L; (2) inject the above two solutions into a three-necked flask at the same flow rate (100 mL / min) via a convection pump , into the three-necked flask in advance to feed nitrogen, and react at 50°C for 30 minutes under stirring conditions; (3) add 200 mL of NaOH aqueous solution with a concentration of 0.4 mol / L, and age for 30 minutes; (4) remove nitrogen, and add a mass fraction of 10 % sodium hypochlorite 20mL, continue to age for 2h; (5) after aging, the resulting suspension is filtered, washed, and dried to prepare a hexagonal cobalt oxyhydroxide with a hollow structure, and the lengths of the six sides of the obtained sample are the same Or different, both are 300-500nm, the longitudinal thickness is 150-200nm, and the volume of the middle cavity is 40%-80% of the total volume of the hexagonal prism. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com