Preparation method and application of photothermal antibacterial agent polypeptide/Au/Fe3O4

A technology of photothermal agent and decomposition method, which is applied in the direction of antibacterial drugs, resistance to vector-borne diseases, and medical preparations containing active ingredients, etc. It can solve problems such as harm, drug-resistant bacteria not working, and limit antibacterial infection. Achieve the effect of improving utilization rate, reducing damage and good targeted sterilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Preparation of Fe 3 o 4 NPs: Iron ferric oxide nanoparticles were prepared by high-temperature reduction decomposition method, the specific steps are as follows: Weigh 0.706g iron acetylacetonate (Fe(acac) 3 ) into a three-necked flask, then measure 10mL of dibenzyl ether, 10mL of oleylamine, and 50mL of ethanol into the flask, and then stir at 110°C for 1h for dehydration. The temperature was then raised to 300 °C and stirring was continued for 2 h. Naturally cool to room temperature after the end, and then centrifuge at 8000rpm to obtain a black product, and use a strong magnet to wash the product three times with hexane, ethanol, and water. Then place it in an oven at 60°C for 12 hours.

[0029] (2) Preparation of Au / Fe 3 o 4 Core-shell composite: Weigh the Fe prepared in step 1 3 o 4 0.01 g of NPs was redispersed in 40 mL of distilled water in an ice bath, and then 0.6 mL of chloroauric acid (HAuCl 4 ) solution, while adding 0.2mL of sodium carbonate (Na...

Embodiment 2

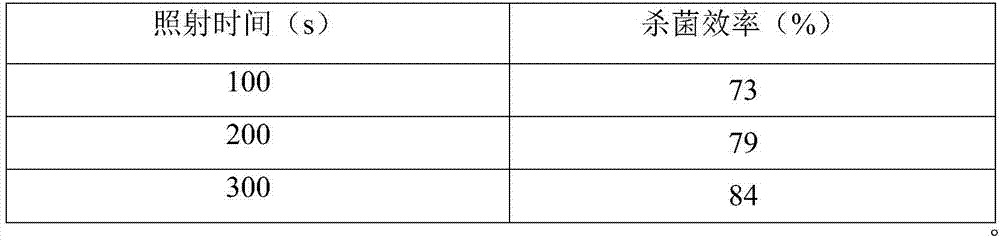

[0033] Same as Example 1, only 1.2 and 2.4 mL added in step (2) of Example 1 were changed. i.e. final Fe 3 o 4 with HAuCl 4 The mass ratios are 5:1.5 and 5:6. The final sterilization rate is shown in Table 1. The results showed that with the increase of the amount of Au, the peptide / Au / Fe 3 o 4 The photothermal efficiency is improved accordingly, and the final sterilization rate is improved.

[0034] Table 1 The amount of different Au versus polypeptide / Au / Fe 3 o 4 The effect of the bactericidal efficiency of

[0035] Fe 3 o 4 with HAuCl 4 mass ratio

Embodiment 3

[0037] Same as Example 1, only change polypeptide / Au / Fe in Example 1 step (4) 3 o 4 The concentration is 200, 300μg / mL. The final photothermal sterilization rate is shown in Table 2. The results showed that with the peptide / Au / Fe 3 o 4 As the concentration increases, the final photothermal sterilization efficiency increases accordingly.

[0038] Table 2 Different polypeptides / Au / Fe 3 o 4 The effect of concentration on its bactericidal efficiency

[0039] Peptide / Au / Fe 3 o 4 Concentration (μg / mL)

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com