Fertilizer special for grapes and preparation method of fertilizer

A special fertilizer and grape technology, applied in the field of fertilizer production, to achieve the effects of small dosage, improved synergy, and increased nutrient content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

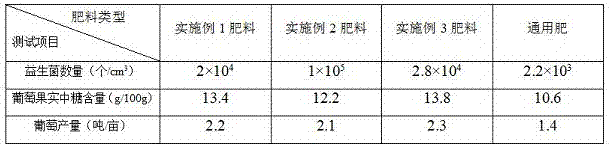

Embodiment 1

[0040] A. Raw material pretreatment

[0041] (1) Take sugarcane tips and leaves, remove impurities, crush them with a pulverizer to obtain raw material slag, and then send them to a steam blaster for blasting treatment to obtain bagasse powder;

[0042] The steam explosion treatment is carried out in two stages. The steam explosion pressure of the first stage is 1.6MPa, and the pressure holding time is 200s; the steam explosion steam pressure of the second stage is 2.8MPa, and the pressure holding time is 140s.

[0043] (2) Add bagasse powder to 5-8% of its mass in ionic liquid, heat and stir to 80°C under nitrogen protection, keep warm for 10 minutes, then add 10% solid acid catalyst, heat to 200°C, and react for 5 hours to obtain a degradation mixture;

[0044] Described ionic liquid is made up of cholyl cation and glycine anion, and its water content is 80%;

[0045] (3) Cool down the degradation mixture to 60°C, add an equal volume of warm water at 60°C, mix well, centri...

Embodiment 2

[0053] A. Raw material pretreatment

[0054] (1) Take sugarcane tips and leaves, remove impurities, crush them with a pulverizer to obtain raw material slag, and then send them to a steam blaster for blasting treatment to obtain bagasse powder;

[0055] The steam explosion treatment is divided into two stages, the first stage explosion steam pressure is 1.2MPa, and the pressure holding time is 240s; the second stage steam explosion steam pressure is 2MPa, and the pressure holding time is 160s.

[0056] (2) Add bagasse powder to 5% ionic liquid by mass, heat and stir to 60°C under nitrogen protection, keep warm for 10min, then add 5% solid acid catalyst, heat to 180°C, and degrade after 3h of reaction time mixture;

[0057] Described ionic liquid is made up of cholyl cation and alanine anion, and its water content is 50%;

[0058] (3) Cool down the degradation mixture to 50°C, add an equal volume of warm water at 50°C, mix well, centrifuge at 17000rpm for 15min, wash the resi...

Embodiment 3

[0066] A. Raw material pretreatment

[0067] (1) Take sugarcane tips and leaves, remove impurities, crush them with a pulverizer to obtain raw material slag, and then send them to a steam blaster for blasting treatment to obtain bagasse powder;

[0068] The steam explosion treatment is divided into two stages, the first stage explosion steam pressure is 1.4MPa, and the pressure holding time is 220s; the second stage steam explosion steam pressure is 2.2MPa, and the pressure holding time is 150s.

[0069] (2) Add bagasse powder to 6% of its mass ionic liquid, heat and stir to 65°C under nitrogen protection, keep warm for 10min, then add 6% solid acid catalyst, heat to 180°C, and degrade after 4h of reaction time mixture;

[0070] Described ionic liquid is made up of cholyl cation and lysine anion, and its water content is 60%;

[0071] (3) Cool down the degradation mixture to 50°C, add an equal volume of warm water at 50°C, mix well, centrifuge at 17,000rpm for 20min, wash th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com