Preparation method for wheat straw nano-cellulose whiskers

A technology of nano-cellulose and wheat straw, which is applied in the fields of cellulose raw material pulping, fiber raw material, fiber raw material treatment, etc., can solve the problems of low production rate, large discrete size, etc., and achieve high specific surface area and high transparency , high-purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

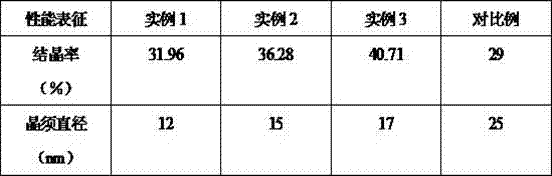

example 1

[0019] Take 3kg of wheat straw and cut it into 5cm pieces, wash it twice, put it in a drying oven at 60°C and dry it for 2 hours, then transfer it to a steam explosion tank, and put water vapor at 220°C into the steam explosion tank to reach the pressure After holding for 3 minutes, open the valve of the steam explosion tank to release the pressure, take out the straw and wash it twice with 80°C deionized water. In a 0.3% sodium chlorite solution, heat and react at 70°C for 40 minutes, filter to obtain a filter cake, wash the filter cake with deionized water for 3 times, air-dry it naturally, and then transfer to 6L containing 0.75% potassium hydroxide and 0.25% In the mixed solution of sodium sulfide, heat the reaction at 80°C for 1 hour, adjust the pH to neutral with glacial acetic acid after cooling to room temperature, filter to obtain the filtrate, wash the filtrate with deionized water for 3 times, and then place it in an 80°C drying oven Dry for 2 hours to obtain wheat ...

example 2

[0021] Take 4kg of wheat straw and cut it into 57cm fragments, wash it twice, put it in a drying oven at 62°C for 2.5 hours, then transfer it to a steam explosion tank, and pass water vapor at a temperature of 235°C into the steam explosion tank The pressure is 2MPa, keep it for 4 minutes, open the valve of the steam explosion tank to release the pressure, take out the straw and wash it twice with 82°C deionized water, and dry it naturally to get the steam explosion treated wheat straw, take 250g of the steam exploded wheat straw, add 7.5L quality Fraction of 0.3% sodium chlorite solution, at 72 ° C, heated for 50 minutes, filtered to obtain a filter cake, washed with deionized water 3 times and then air-dried, then transferred to 7L containing 0.75% potassium hydroxide and 0.25 % sodium sulfide mixed solution, heated at 85°C for 1.5h, cooled to room temperature, adjusted pH to neutral with glacial acetic acid, filtered to obtain filtrate, washed with deionized water for 4 time...

example 3

[0023]Take 35kg of wheat straw and cut it into 10cm fragments, wash it with water for 3 times, put it in a drying oven at 65°C for 3 hours, then transfer it to a steam explosion tank, and put water vapor at 250°C into the steam explosion tank to reach the pressure After holding for 5 minutes, open the valve of the steam explosion tank to release the pressure, take out the straw and wash it three times with 85°C deionized water, and dry it naturally to obtain steam explosion treated wheat straw. Take 300g of steam exploded wheat straw and add 9L mass fraction In a 0.3% sodium chlorite solution, heat and react at 75°C for 60 minutes, filter to obtain a filter cake, wash the filter cake with deionized water for 5 times, air-dry it naturally, and then transfer it to 9L containing 0.75% potassium hydroxide and 0.25% In the mixed solution of sodium sulfide, heat the reaction at 90°C for 2 hours, adjust the pH to neutral with glacial acetic acid after cooling to room temperature, filt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com