A kind of flaky oxygen-deficient lithium vanadate positive electrode material and preparation method thereof

A cathode material, lithium vanadate technology, applied in battery electrodes, structural parts, electrical components, etc., can solve the problems of large irreversible capacity loss, complex post-processing steps, large resistance between large particles, etc., to improve electronic conductivity and The effect of lithium ion diffusivity, low electrode production cost, and easy large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Dissolve 2.632g ammonium vanadate and 0.765g lithium acetate in 5g N,N dimethylformamide according to the stoichiometric ratio, and add 0.5ml HNO 3 and 5.673g C 2 h 2 o 4 2H 2 O is complexed and adjusted, stirring continuously until it is completely dissolved to form a solution A; then 2g of polyacrylonitrile with a molecular weight of 50000 and 4g of a molecular weight of 150000 is dissolved in 30g N, N dimethylformamide to form a solution B; the solution A is slowly Add dropwise to solution B and stir until evenly mixed.

[0029] (2) Prepare the lithium vanadate precursor fiber by using the general electrospinning method from the mixed solution. The feeding speed is 0.5ml / h, the voltage is 24kV, the humidity is controlled at 40%, and the temperature is kept at 25°C. The distance between them is 15cm;

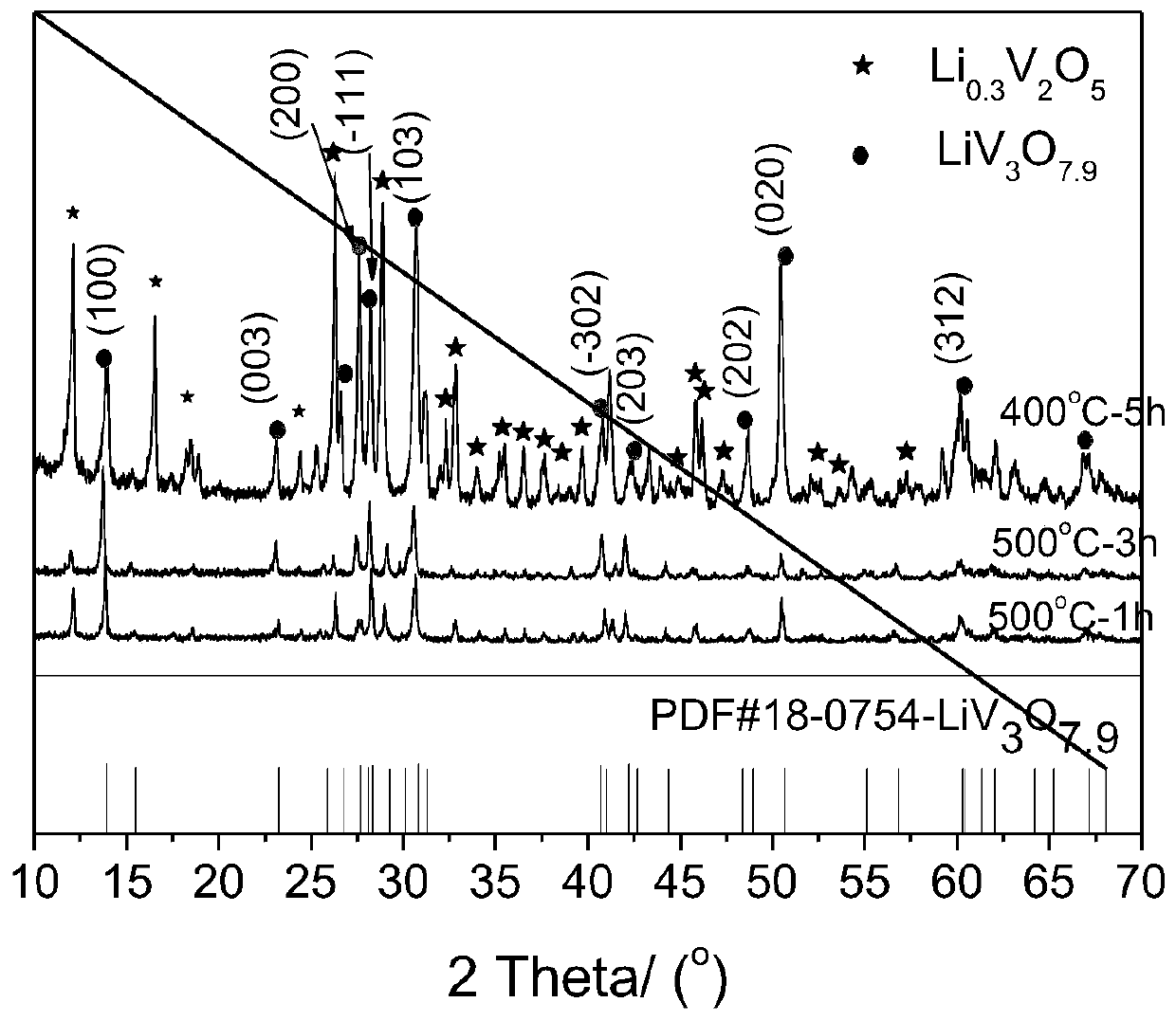

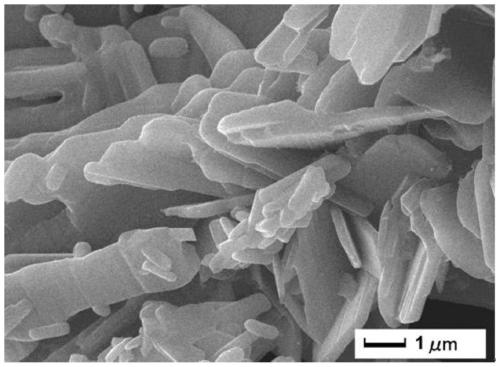

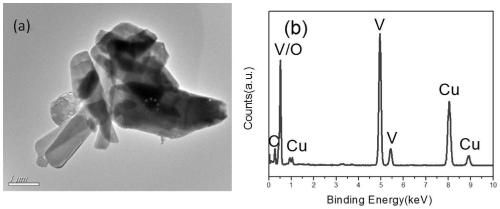

[0030] (3) The precursor fiber was directly calcined at 500° C. in air for 3 hours to obtain a surface-modified sheet-like oxygen-deficient lithium vanadate ca...

Embodiment 2

[0033] (1) Dissolve 1.316g of ammonium vanadate and 0.383g of lithium acetate in 3g of N,N dimethylacetamide according to the stoichiometric ratio, and add 0.3ml of HNO 3 and 2.837g C 2 h 2 O4·2H 2 O is complexed and adjusted, stirring continuously until it is completely dissolved to form a solution; then 1g of polyacrylonitrile with a molecular weight of 50000 and 4g of a molecular weight of 150000 is dissolved in 30g of N,N dimethylacetamide to form a solution of B; the solution of A is slowly Add dropwise to solution B and stir until evenly mixed.

[0034] (2) Use the general electrospinning method to prepare the lithium vanadate precursor fiber from the mixed solution, such as the feeding speed is 0.5ml / h, the voltage is 20kV, the humidity is controlled at 40%, the temperature is kept at 25°C, the nozzle and the receiver The distance between them is 15cm;

[0035] (3) The precursor fiber was directly calcined at 400° C. in air for 5 hours to obtain a surface-modified s...

Embodiment 3

[0038] (1) Dissolve 5.264g of ammonium vanadate and 1.53g of lithium acetate in 10g of acetonitrile according to the stoichiometric ratio, and add 1ml of HNO 3 and 11.346g C 2 h 2 O4·2H 2 O is complexed and adjusted, stirring continuously until completely dissolving to form A solution; then 4g of molecular weight is 50000 and 8g of polyacrylonitrile with molecular weight of 150000 is dissolved in 55g of acetonitrile to form B solution; A solution is slowly added dropwise to B solution, Stir until well combined.

[0039] (2) Prepare the lithium vanadate precursor fiber by using the general electrospinning method from the mixed solution. The feeding speed is 0.5ml / h, the voltage is 24kV, the humidity is controlled at 40%, and the temperature is kept at 25°C. The distance between them is 15cm;

[0040] (3) The precursor fiber was directly calcined at 500° C. in air for 1 hour to obtain a surface-modified sheet-like oxygen-deficient lithium vanadate cathode material.

[0041]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com