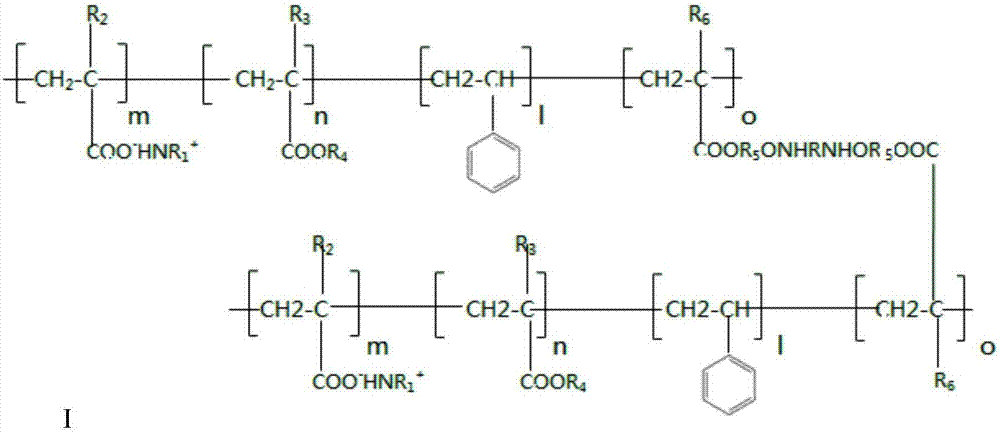

Water-soluble polyurethane modified acrylic acid polymer as well as preparation method and application thereof

A water-soluble polyurethane and acrylic polymer technology, applied in the field of coatings, can solve the problems of short pot life, difficult construction, uneven mixing on the construction site, etc., and achieve the effect of excellent water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

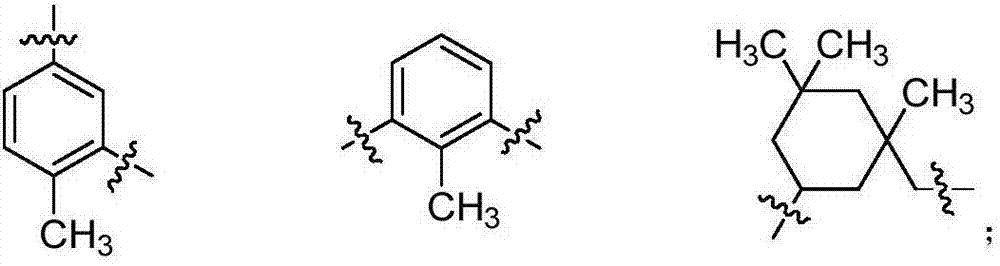

Method used

Image

Examples

Embodiment 1

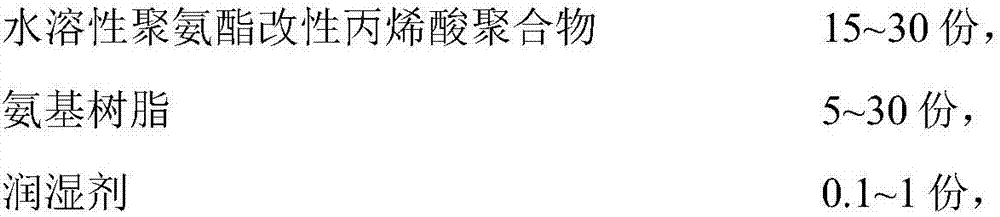

[0067] 1. The formula of water-soluble polyurethane modified acrylic acid polymer is as shown in table 1:

[0068] Table 1

[0069] name

Specification

Weight (parts)

Propylene glycol methyl ether acetate

Industrial products

45

Industrial products

5

Industrial products

16

Industrial products

2

Industrial products

15

Hydroxybutyl Acrylate

Industrial products

5

tert-butyl peroxybenzoate

Industrial products

6

Toluene diisocyanate

Industrial products

2

Isopropanol

Industrial products

10

Industrial products

7

[0070] 2. the preparation method of water-soluble polyurethane modified acrylic acid polymer comprises the following steps:

[0071] Add 45 parts of propylene glycol methyl ether acetate, stir and heat up to reflux, drop 16 parts...

Embodiment 2

[0076] 1. The formula of water-soluble polyurethane modified acrylic acid polymer is as shown in table 2:

[0077] Table 2

[0078] name

Specification

Weight (parts)

dibasic acid ester

Industrial products

49

acrylic acid

Industrial products

6

Industrial products

16

Industrial products

5

Industrial products

13

Hydroxypropyl Acrylate

Industrial products

7

tert-butyl peroxybenzoate

Industrial products

5

Toluene diisocyanate

Industrial products

3

ethanol

Industrial products

14

Industrial products

8

[0079] 2. the preparation method of water-soluble polyurethane modified acrylic acid polymer comprises the following steps:

[0080] Put 49 parts of dibasic acid ester, stir and heat up to reflux, drop 16 parts of styrene, 5 parts of methyl methacrylate, 6 pa...

Embodiment 3

[0085] 1. The formula of water-soluble polyurethane modified acrylic acid polymer is as shown in table 3:

[0086] table 3

[0087] name

Specification

Weight (parts)

dibasic acid ester

Industrial products

48

Industrial products

7

Industrial products

16

Industrial products

5

Industrial products

15

Hydroxyethyl Acrylate

Industrial products

5

tert-butyl peroxybenzoate

Industrial products

5

Isophorone diisocyanate

Industrial products

3

ethanol

Industrial products

14

Industrial products

6

[0088] 2. the preparation method of water-soluble polyurethane modified acrylic acid polymer comprises the following steps:

[0089] Put in 48 parts of dibasic acid ester, stir and heat up to reflux, add dropwise 16 parts of styrene, 5 parts of i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dispersity | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com