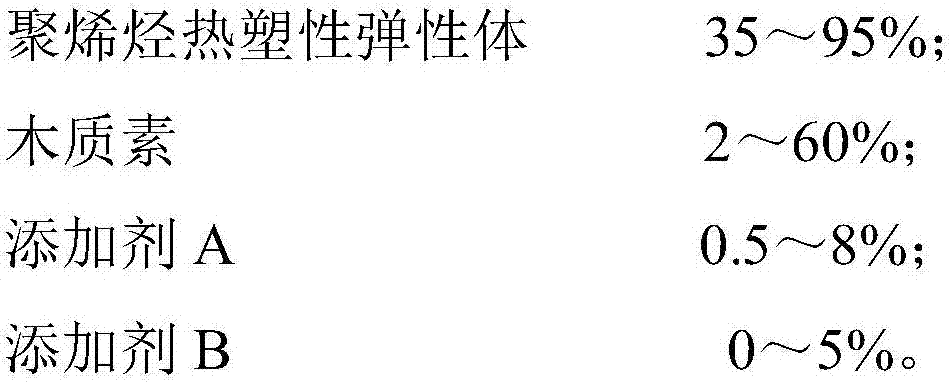

Lignin/polyolefin thermoplastic elastomer composite and preparation method thereof

A technology of thermoplastic elastomer and composite material, which is applied in the field of lignin/polyolefin thermoplastic elastomer composite material and its preparation, can solve the problems of decreased tensile strength and elongation at break, and achieve low raw material cost and excellent UV resistance Radiation and anti-aging functions, the effect of improving interface compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

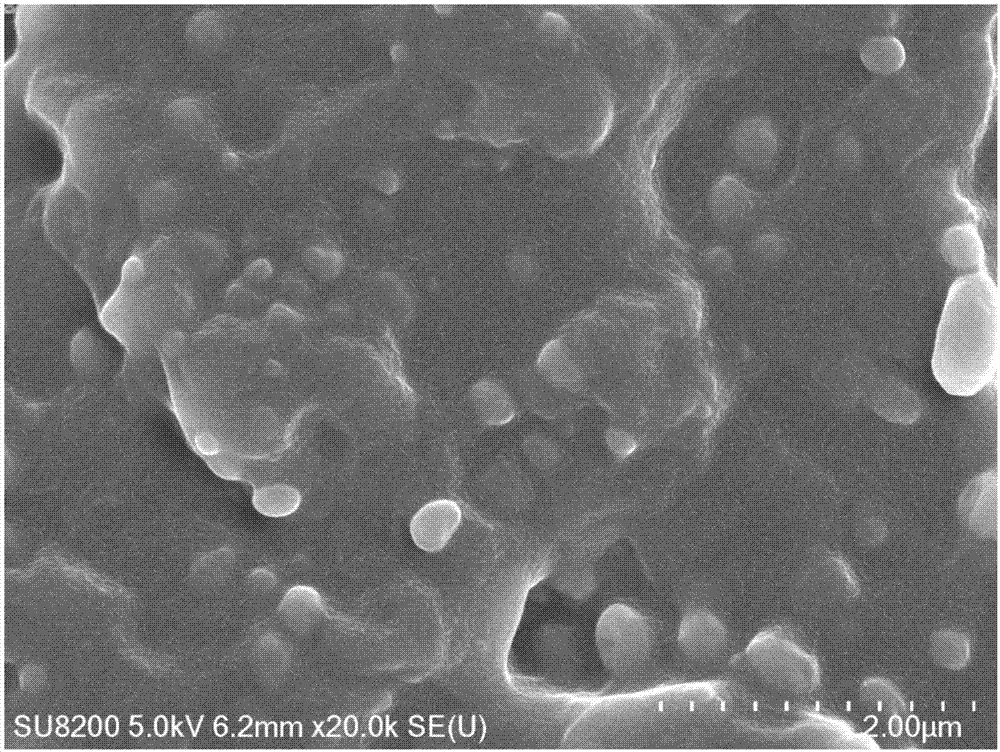

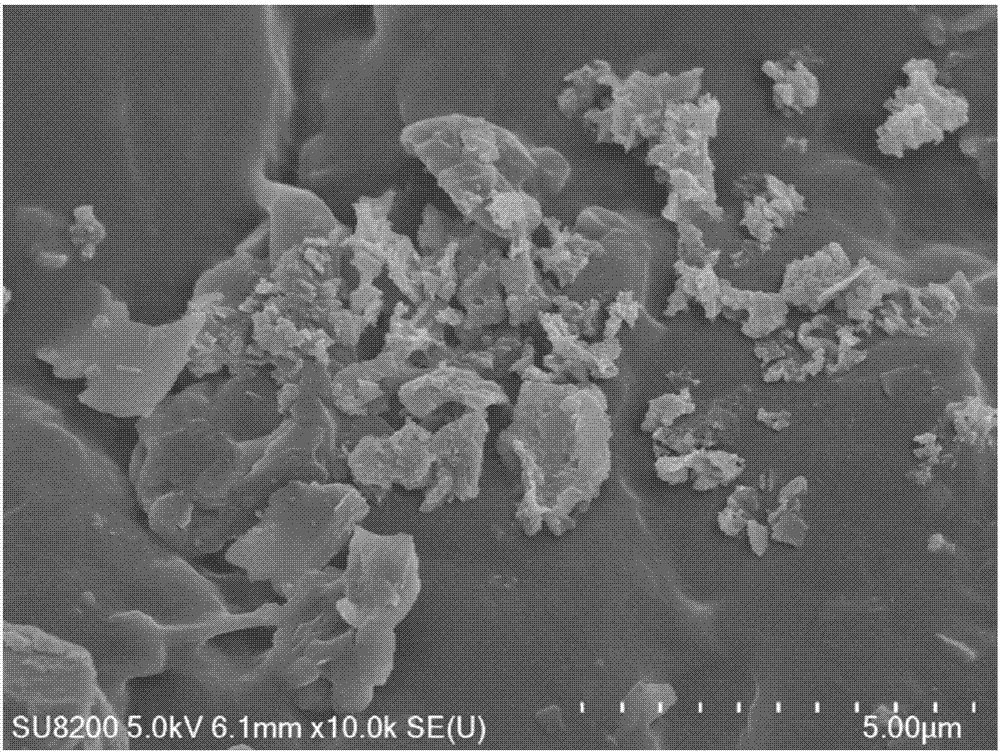

Image

Examples

Embodiment 1

[0031] Preheat the internal mixer to 100°C, add 32 grams of dry POE-8150 to melt, then add 1 gram of 3-amino-1,2,4 triazole; after melting and mixing for 10 minutes, add 8 grams of enzymatic lignin powder and 1 gram of zinc chloride, continue to knead for 15 minutes, and discharge the material to obtain a lignin / polyolefin thermoplastic elastomer composite material. The selected POE-8150 is a random copolymer elastomer of ethylene and 1-octene produced by Dow Chemical Company of the United States (the same below).

Embodiment 2

[0033] Preheat the internal mixer to 100°C, add 32 grams of dry POE-8150 grafted with maleic anhydride to melt, then add 1 gram of 3-amino-1,2,4 triazole; after 10 minutes of melt mixing , add 8 grams of enzymatic lignin powder and 1 gram of zinc chloride, continue mixing for 15 minutes, and then discharge the material to obtain a lignin / polyolefin thermoplastic elastomer composite material. Wherein, the grafting amount of maleic anhydride in POE-8150 modified by grafting maleic anhydride is 0.8-2% (mass fraction) (the same below).

Embodiment 3

[0035] Preheat the internal mixer to 100°C, add 36 grams of dry POE-8150 grafted with maleic anhydride to melt, then add 1 gram of 3-amino-1,2,4 triazole; after 10 minutes of melt mixing , add 4 grams of enzymatic lignin powder and 1 gram of zinc chloride, continue mixing for 15 minutes, and discharge the material to obtain a lignin / polyolefin thermoplastic elastomer composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com