Dechlorination process in zinc hydrometallurgy

A technology of hydrometallurgy and dechlorination, applied in the direction of improving process efficiency, etc., can solve the problems of low silver regeneration capacity, complicated treatment process, poor dechlorination effect, etc., achieve control of chloride ion concentration, simple and good treatment method The effect of dechlorination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

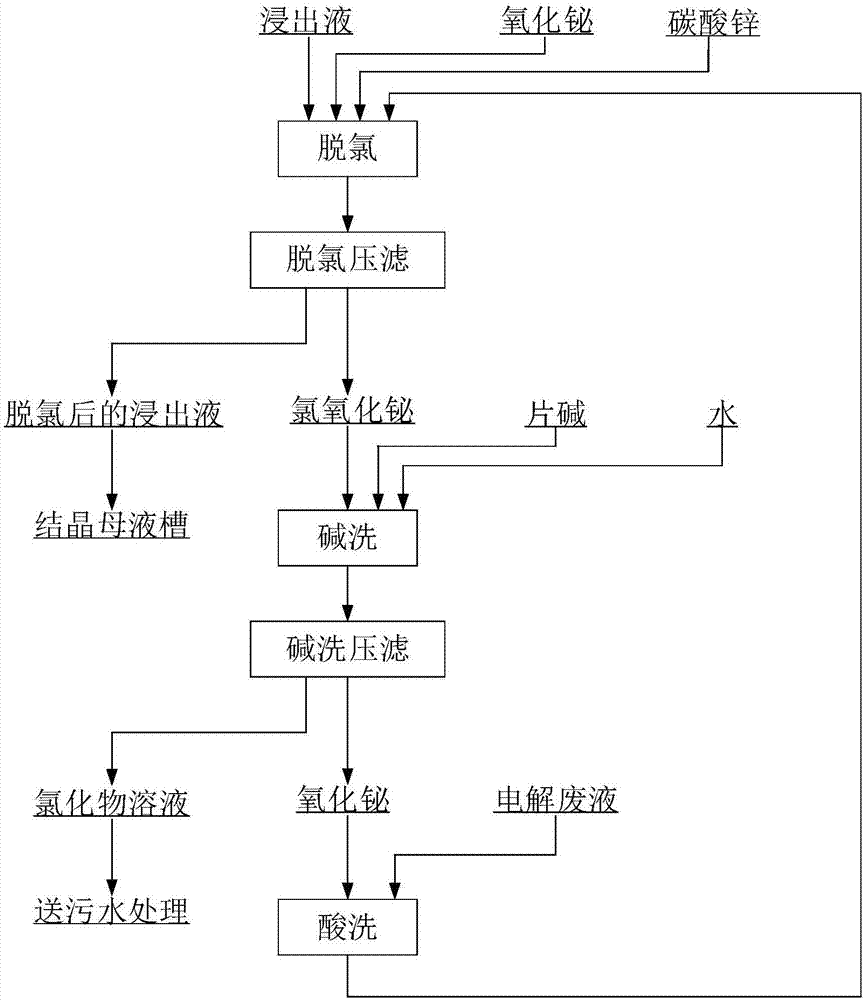

[0018] see figure 1 , which is a schematic diagram of the dechlorination process flow of the embodiment, comprising the following steps:

[0019] Dechlorination treatment: the leaching solution after roasting the zinc concentrate in the hydrometallurgy (the chlorine concentration of the leaching solution is 500-800mg / L, and the amount of the leaching solution is 360m 3 ) into the dechlorination tank, add bismuth oxide 63kg, following reaction takes place: Bi 2 o 3 +6H + =2Bi 3+ +3H 2 O; Bi 3+ +3Cl - =BiCl 3 ↓; BiCl 3 +H 2 O=BiOCl↓+2HCl. Control the reaction temperature at 60-75°C, and the reaction time at 40-60 minutes. Add basic zinc carbonate at the end of the reaction, adjust the pH value to 3.5-4.5, and continue the reaction for 15-20 minutes. After the reaction, the mixture is pumped to the Chlorine filter press filter to obtain BiOCl precipitation and dechlorination leaching solution (chlorine concentration is about 200mg / L); dechlorination leaching solution f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com