Conductor rail and preparation method thereof and super stainless steel power

A technology of stainless steel and conductive rails, which is applied in the direction of electric power rails, metal material coating technology, molten spraying, etc., can solve the problems of short service life of wear-resistant layer, shedding of wear-resistant cladding, low bonding strength, etc., and achieve service life Long, easy to install, good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

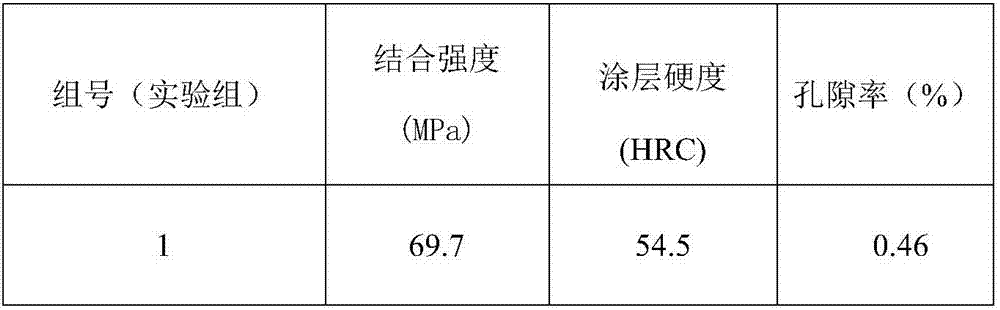

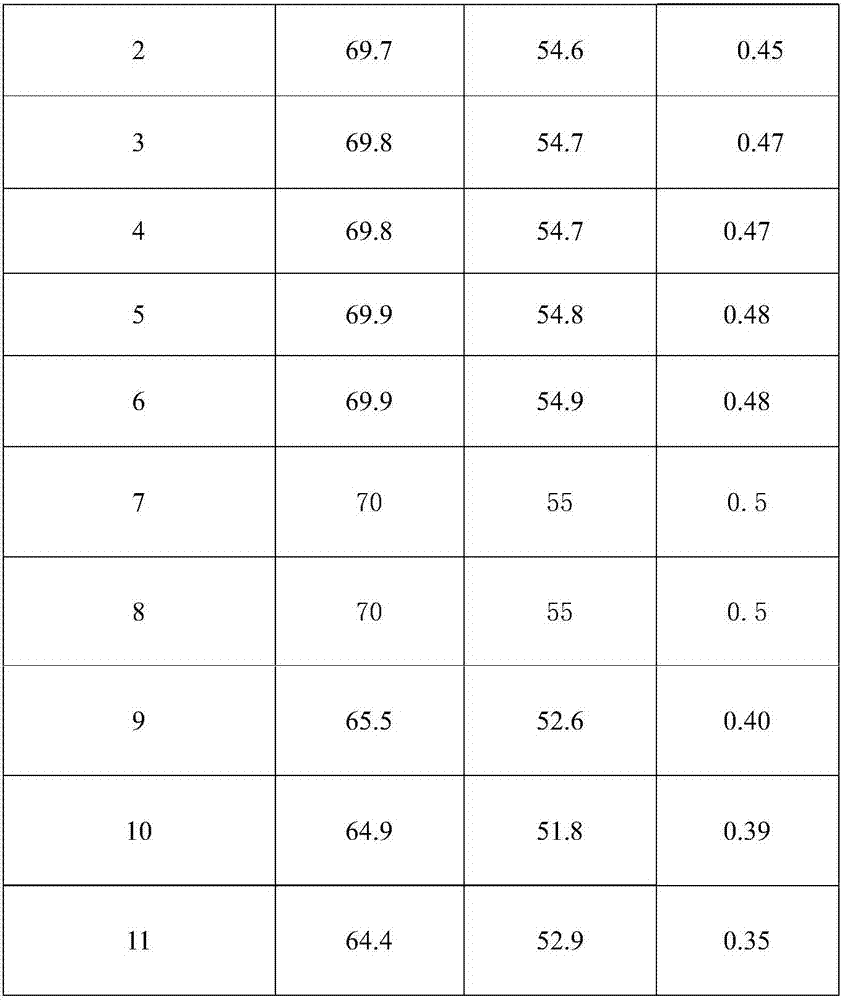

Examples

Embodiment 1

[0036] A super stainless steel powder is made of the following mass ratio: the mass ratio of nickel, chromium, molybdenum, carbon and iron is 2:15:1:0.4:81.6;

[0037] An aluminum alloy matrix is made of the following mass ratio: the mass ratio of aluminum, silicon, iron, copper, manganese, magnesium and chromium is 98.75:0.25:0.30:0.05:0.05:0.55:0.05;

[0038] The raw material of a kind of conductive rail comprises above-mentioned super stainless steel powder and aluminum alloy substrate;

[0039] A preparation method of a conductive rail comprises: (1) using an alcohol aluminum alloy substrate surface to carry out degreasing and decontamination treatment; (2) uniformly sandblasting the sprayed surface to make the sprayed surface rough; (3) debugging the manipulator to make the spray gun Move at a constant speed on the spraying surface, turn on the oxykerosene supersonic spraying equipment and pass compressed air to the surface of the workpiece to ensure that the surface te...

Embodiment 2

[0041] A super stainless steel powder is made of the following mass ratio: the mass ratio of nickel, chromium, molybdenum, carbon and iron is 15:29:4:1.8:50.2;

[0042] An aluminum alloy matrix is made of the following mass ratio: the mass ratio of aluminum, silicon, iron, copper, manganese, magnesium and chromium is 98.75:0.25:0.30:0.05:0.05:0.55:0.05;

[0043] The raw material of a kind of conductive rail comprises above-mentioned super stainless steel powder and aluminum alloy substrate;

[0044] A preparation method of a conductive rail comprises: (1) using an alcohol aluminum alloy substrate surface to carry out degreasing and decontamination treatment; (2) uniformly sandblasting the sprayed surface to make the sprayed surface rough; (3) debugging the manipulator to make the spray gun Move at a constant speed on the spraying surface, turn on the oxykerosene supersonic spraying equipment and pass compressed air to the surface of the workpiece to ensure that the surface t...

Embodiment 3

[0046] A super stainless steel powder is made of the following mass ratio: the mass ratio of nickel, chromium, molybdenum, carbon and iron is 11:25:3:1:60;

[0047] An aluminum alloy matrix is made of the following mass ratio: the mass ratio of aluminum, silicon, iron, copper, manganese, magnesium and chromium is 98.75:0.25:0.30:0.05:0.05:0.55:0.05;

[0048] The raw material of a kind of conductive rail comprises above-mentioned super stainless steel powder and aluminum alloy substrate;

[0049] A preparation method of a conductive rail comprises: (1) using an alcohol aluminum alloy substrate surface to carry out degreasing and decontamination treatment; (2) uniformly sandblasting the sprayed surface to make the sprayed surface rough; (3) debugging the manipulator to make the spray gun Move at a constant speed on the spraying surface, turn on the oxykerosene supersonic spraying equipment and pass compressed air to the surface of the workpiece to ensure that the surface tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com