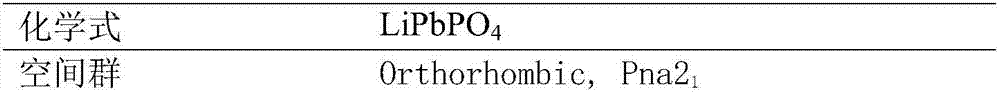

Method for growing large-size lithium lead phosphate single crystals through hydrothermal method

A technology of lead lithium phosphate and hydrothermal method, which is applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problem that the nonlinear material of lead lithium phosphate has not been effectively applied and developed, and affects the photoelectric performance of the material and the optical quality of the crystal. Poor and other problems, to achieve the effect of small stress, good compatibility and high utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) Take LiH 2 PO 4 Use distilled water to make LiH with a concentration of 3mol / L 2 PO 4 The solution is used as a mineralizer for standby;

[0025] 2) Weigh lead chloride (PbCl 2 )56g, lithium dihydrogen phosphate (LiH 2 PO 4 ) 21g, ball milled and mixed evenly as a hydrothermal reactant, placed at the bottom of the gold bushing tube (reaction chamber Φ35mm) of the autoclave;

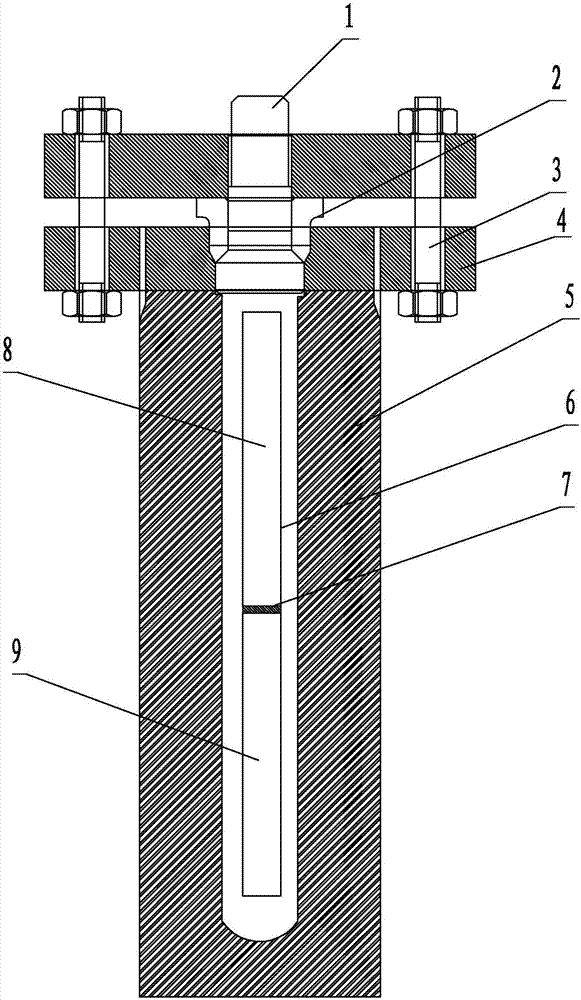

[0026] 3) Add 154mL of mineralizer into the gold bushing tube (the filling degree of mineralizer is 65%, the solid-liquid ratio of hydrothermal reactant and mineralizer is 0.5g:1mL), and hang a A gold wire is used to weld and seal the gold bushing tube, and then put it into an autoclave with a matching caliber;

[0027] 4) Fill 65% volume of deionized water between the outer wall of the gold liner pipe and the interlayer of the inner wall of the autoclave, and seal the autoclave;

[0028] 5) Put the sealed autoclave into a two-stage heating resistance furnace, set the average temperature...

Embodiment 2

[0034] 1) Take LiH 2 PO4 Use distilled water to make LiH with a concentration of 5mol / L 2 PO 4 The solution is used as a mineralizer for standby;

[0035] 2) Weigh lead fluoride (PbF 2 ) 100g, lithium dihydrogen phosphate (LiH 2 PO 4 ) 42.4g, ball milled and mixed uniformly as a hydrothermal reactant, placed at the bottom of the gold bushing tube (reaction chamber Φ35mm) of the autoclave;

[0036] 3) Add 142.4mL of mineralizer into the gold bushing tube (the filling degree of mineralizer is 70%, the solid-liquid ratio of hydrothermal reactant and mineralizer is 1g:1mL), and hang a A gold wire, hang 2 lead-lithium phosphate monochips (respectively (001) and (011) directions) on the gold wire, weld and seal the gold bushing tube, and then put it into an autoclave with a matching caliber;

[0037] 4) Fill 70% volume of deionized water between the outer wall of the gold liner tube and the interlayer of the inner wall of the autoclave, and seal the autoclave;

[0038] 5) Put...

Embodiment 3

[0040] 1) Take LiH 2 PO 4 Use distilled water to make LiH with a concentration of 1mol / L 2 PO 4 The solution is used as a mineralizer for standby;

[0041] 2) Weigh lead nitrate (PbSO 4 ) 46g, lead phosphate (Pb 3 (PO 4 ) 2 ) 121.7g, lithium dihydrogen phosphate (LiH 2 PO 4 ) 31.5g, ball milled and mixed evenly as a hydrothermal reactant, placed at the bottom of the gold bushing tube (reaction chamber Φ30mm) of the autoclave;

[0042] 3) Add 132.8mL of mineralizer to the gold bushing tube (the filling degree of mineralizer is 80%, the solid-liquid ratio of hydrothermal reactant and mineralizer is 1.5g: 1mL), and hang it on the top of the gold bushing tube A gold wire, two primary crystals of lithium lead phosphate are hung on the gold wire, the gold bushing tube is welded and sealed, and then put into an autoclave with a matching caliber;

[0043] 4) Fill 80% volume of deionized water between the outer wall of the gold liner pipe and the interlayer of the inner wall ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com