Silver nanoparticles-assembled monolayer inverse opal structure, and preparation method and use thereof

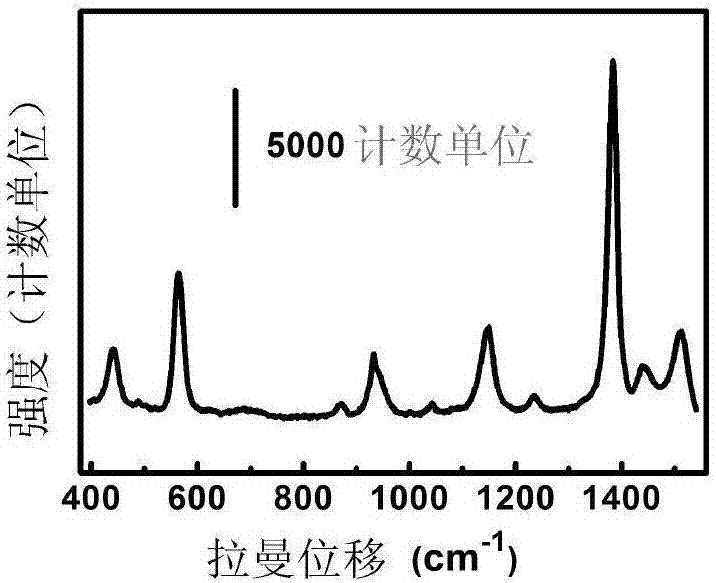

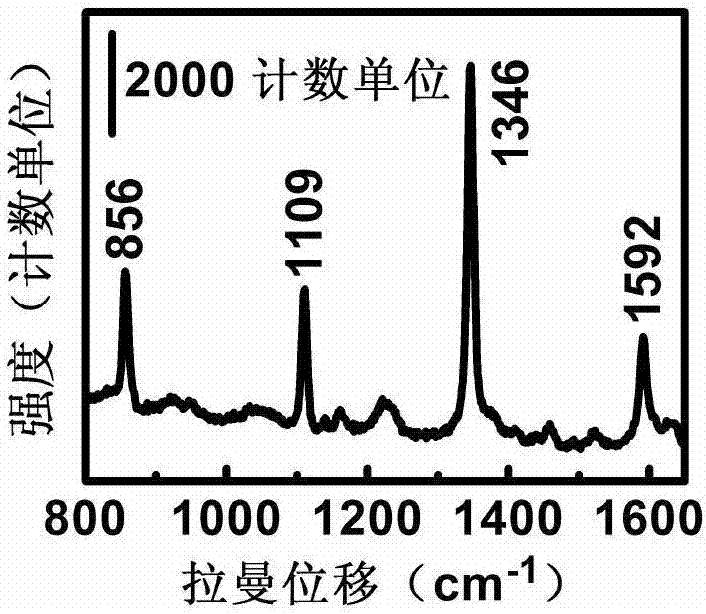

An inverse opal structure, silver nanoparticle technology, applied in nanotechnology, coatings, measurement devices, etc., can solve the problem that the uniformity and reproducibility of SERS signals are difficult to guarantee, difficult to achieve quantitative or semi-quantitative detection, and difficult to detect. To solve problems such as trace residues of pesticides in vegetables, it can achieve the effects of easy industrial preparation, avoiding interference of background signals and stabilizing the structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

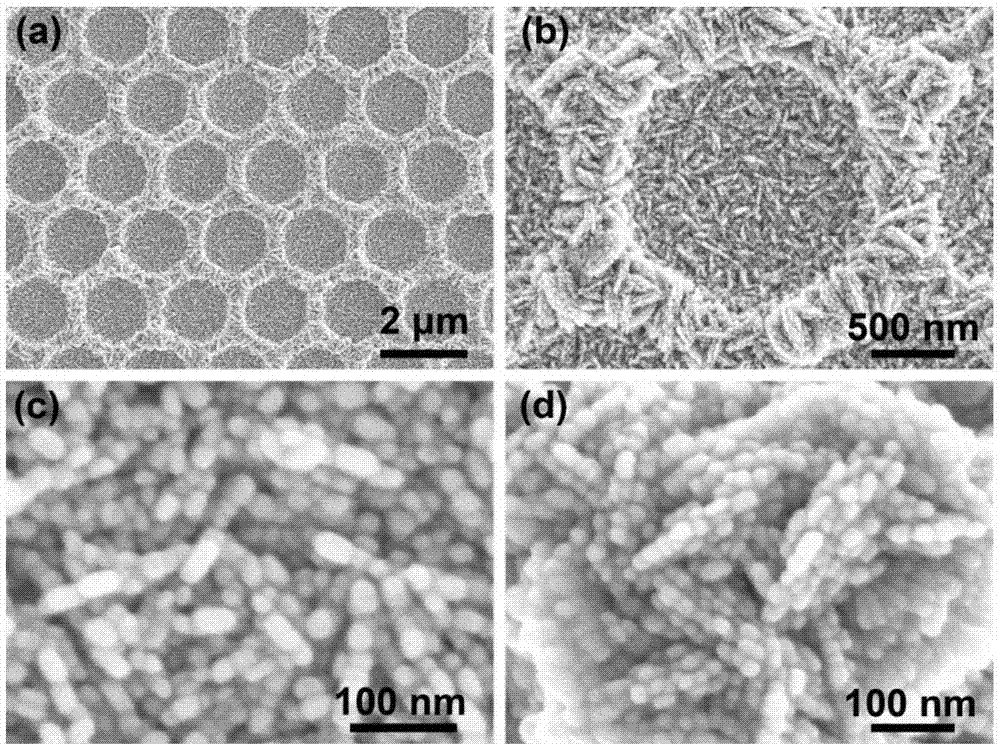

[0042] The concrete steps of preparation are:

[0043] Step 1, first synthesize a single layer of colloidal crystals with colloidal spheres with a particle size of 100nm on the substrate, and then place them at 105°C for 10 minutes; wherein, the colloidal spheres are polystyrene colloidal spheres, and the conductive substrate is indium tin oxide A glass substrate was obtained on which a single-layer colloidal crystal template was placed. Then, after filling 0.1mol / L aluminum nitrate aqueous solution between the colloidal spheres forming the single-layer colloidal crystal template, place it at 105°C for 70 minutes; wherein, the filling is dropwise, and the single-layer colloidal crystal template is sequentially placed on it. and aluminum nitrate substrate.

[0044] Step 2, first use chemical or physical methods to remove the single-layer colloidal crystal template on the substrate on which the single-layer colloidal crystal template and aluminum nitrate are placed sequentially, ...

Embodiment 2

[0047] The concrete steps of preparation are:

[0048] Step 1, first synthesize a single layer of colloidal crystals with colloidal spheres with a particle size of 500nm on the substrate, and then place them at 110°C for 9 minutes; wherein, the colloidal spheres are polystyrene colloidal spheres, and the conductive substrate is indium tin oxide A glass substrate was obtained on which a single-layer colloidal crystal template was placed. After filling the colloidal spheres forming the single-layer colloidal crystal template with 0.15mol / L aluminum nitrate aqueous solution, place it at 110°C for 65 minutes; wherein, the filling is dropwise, and the single-layer colloidal crystal template is sequentially placed on it. and aluminum nitrate substrate.

[0049] Step 2, first use chemical or physical methods to remove the single-layer colloidal crystal template on the substrate on which the single-layer colloidal crystal template and aluminum nitrate are placed sequentially, and the...

Embodiment 3

[0052] The concrete steps of preparation are:

[0053] Step 1, first synthesize a single layer of colloidal crystals with colloidal spheres with a particle size of 2 μm on the substrate, and then place them at 115°C for 8 minutes; wherein, the colloidal spheres are polystyrene colloidal spheres, and the conductive substrate is indium tin oxide A glass substrate was obtained on which a single-layer colloidal crystal template was placed. Then, after filling 0.2mol / L aluminum nitrate aqueous solution between the colloidal spheres forming the single-layer colloidal crystal template, place it at 115°C for 60 minutes; among them, the filling is dropwise, and the single-layer colloidal crystal template is sequentially placed on it. and aluminum nitrate substrate.

[0054] Step 2, first use chemical or physical methods to remove the single-layer colloidal crystal template on the substrate on which the single-layer colloidal crystal template and aluminum nitrate are placed sequentiall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com