Anti-corrosion brake pad and preparing method of brake pad

A brake pad and anti-corrosion technology, which is applied in the field of brake pads, can solve the problems of lower mechanical properties of brake pads and reduce the use effect of brake pads, and achieve the effects of improving wear resistance, reducing metal corrosion, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

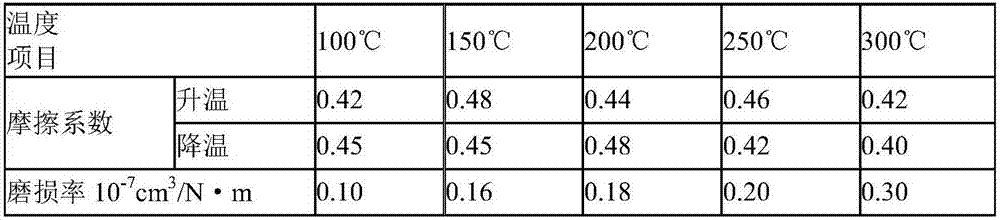

Examples

Embodiment 1

[0035] An anti-corrosion brake pad, comprising the following raw materials in parts by weight: 20 parts of ceramic fiber, 5 parts of carbon fiber, 5 parts of steel fiber, 15 parts of modified phenolic resin, 6 parts of calcium oxide, 6 parts of barium sulfide, and 15 parts of flake graphite , 1 part of zircon, 5 parts of butyl butylbenzene, 10 parts of nitrile powder, 3 parts of molybdenum disulfide, 1 part of binder, 5 parts of barite powder, 0.5 parts of zinc oxide, 5 parts of rubber powder, fluorite powder 1 part, silicon carbide 0.5 part.

[0036]Wherein, the steel fibers are subjected to the following treatment: first, the steel fibers are washed with 6% sodium carbonate solution, washed with water, and then washed with 3% sulfuric acid solution, the steel fibers are taken out and washed with clear water, and then the steel fibers are put into the surface treatment solution , keep the temperature at 75°C and keep it warm for 40 minutes, rinse the soaked steel fibers with ...

Embodiment 2

[0045] An anti-corrosion brake pad, comprising the following raw materials in parts by weight: 25 parts of ceramic fiber, 10 parts of carbon fiber, 10 parts of steel fiber, 18 parts of modified phenolic resin, 10 parts of calcium oxide, 8 parts of barium sulfide, and 20 parts of flake graphite , 3 parts of zircon, 10 parts of butyl styrene, 15 parts of nitrile powder, 5 parts of molybdenum disulfide, 2 parts of binder, 10 parts of barite powder, 3 parts of zinc oxide, 10 parts of rubber powder, fluorite powder 2 parts, silicon carbide 1 part.

[0046] Wherein, the steel fibers are subjected to the following treatment: first, the steel fibers are washed with 6% sodium carbonate solution, washed with water, and then washed with 3% sulfuric acid solution, the steel fibers are taken out and washed with clear water, and then the steel fibers are put into the surface treatment solution , keep the temperature at 75°C and keep it warm for 40 minutes, rinse the soaked steel fibers with...

Embodiment 3

[0055] An anti-corrosion brake pad, comprising the following raw materials in parts by weight: 22 parts of ceramic fiber, 8 parts of carbon fiber, 8 parts of steel fiber, 17 parts of modified phenolic resin, 8 parts of calcium oxide, 7 parts of barium sulfide, and 18 parts of flake graphite , 2 parts of zircon, 6 parts of butyl butylbenzene, 13 parts of nitrile powder, 4 parts of molybdenum disulfide, 1 part of binder, 8 parts of barite powder, 2 parts of zinc oxide, 6 parts of rubber powder, fluorite powder 1 part, silicon carbide 1 part.

[0056] Wherein, the steel fibers are subjected to the following treatment: first, the steel fibers are washed with 6% sodium carbonate solution, washed with water, and then washed with 3% sulfuric acid solution, the steel fibers are taken out and washed with clear water, and then the steel fibers are put into the surface treatment solution , keep the temperature at 75°C and keep it warm for 40 minutes, rinse the soaked steel fibers with di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com