Liquid dressing for preparing pure natural plant extract and preparation method thereof

A technology of liquid dressings and natural plants, applied in medical science, bandages, etc., can solve the problems of functional dressings and liquid dressings with single function, low antibacterial function, and children's unsafety, so as to achieve muscle growth, antisepsis, wound regeneration and healing, and promote The effect of wound regeneration and healing, and the time required for film formation is shortened

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

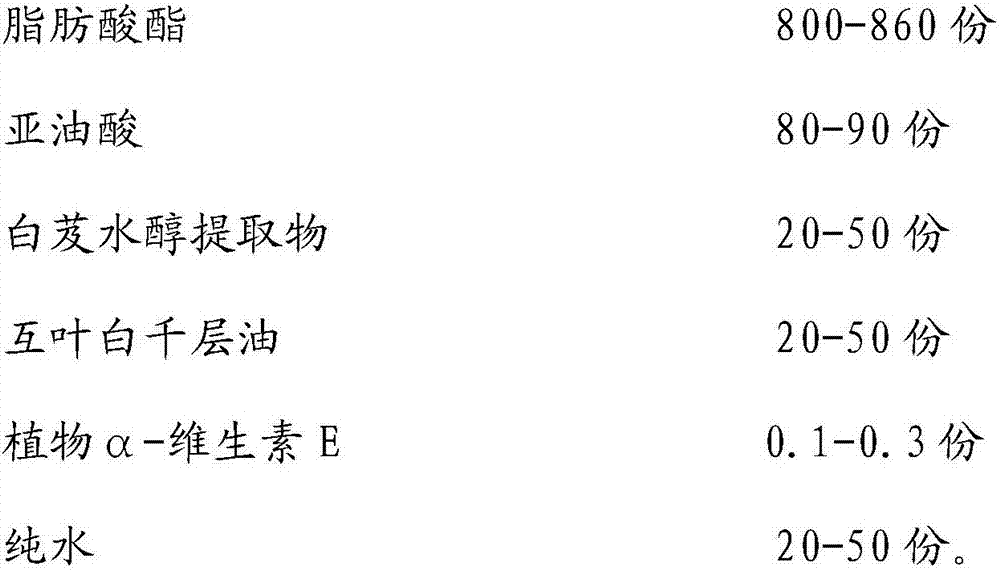

Method used

Image

Examples

Embodiment 1

[0041] (1) Grind the dried bletilla striata pieces, pass through a 10-20 mesh sieve, dry in an oven at 50°C for 1 hour, weigh 200g, add 10 times the amount, namely 2.0L of distilled water, stir evenly, and place overnight. Continue to add water the next day, the ratio of solid to liquid is 1:20, stir and extract in a 60°C water bath for 1 hour, filter and separate the filter residue, and then extract the residue twice. The second water addition is 10 times, the extraction temperature is 60°C and 1h, and filtered; the third water addition is 5 times, the extraction temperature is 90°C, 0.5h, cooled to a temperature of 45-50°C, and adjusted When the pH is 5.0, add 250 U / mg of cellulase solution, keep shaking at 45°C for 5 hours, and boil for 5 minutes to inactivate the enzyme. Combine the filtrates for 3 times, concentrate until viscous, cool to room temperature, add 3 times the volume of ethanol and stir evenly, so that the alcohol content reaches 70%, let it stand overnight, c...

Embodiment 2

[0047] (1) Grind the dried bletilla striata pieces, pass through a 10-20 mesh sieve, dry in an oven at 50°C for 1 hour, weigh 200g, add 10 times the amount (2.0L) of distilled water, stir evenly, and place overnight. Continue to add water the next day, the ratio of solid to liquid is 1:20, stir and extract in a 60°C water bath for 1 hour, filter and separate the filter residue, and then extract the residue twice. The second water addition is 10 times, the extraction temperature is 60°C and 1h, and filtered; the third water addition is 5 times, the extraction temperature is 90°C, 0.5h, cooled to a temperature of 45-50°C, and adjusted When the pH is 5.0, add 250 U / mg of cellulase solution, keep shaking at 45°C for 5 hours, and boil for 5 minutes to inactivate the enzyme. Combine the filtrates for 3 times, concentrate until viscous, then use papain 8-10mg / g at a temperature of 45-50°C and a pH value of 7.0-7.5, refine the treatment for 120-150min, inactivate the enzyme, cool to r...

Embodiment 3

[0052] (1) Grind the dried bletilla striata pieces, pass through a 10-20 mesh sieve, dry in an oven at 50°C for 1 hour, weigh 200g, add 10 times the amount (2.0L) of distilled water, stir evenly, and place overnight. Continue to add water the next day, the ratio of solid to liquid is 1:20, stir and extract in a 60°C water bath for 1 hour, filter and separate the filter residue, and then extract the residue twice. The second water addition is 10 times, the extraction temperature is 60°C and 1h, and filtered; the third water addition is 5 times, the extraction temperature is 90°C, 0.5h, cooled to a temperature of 45-50°C, and adjusted When the pH is 5.0, add 250 U / mg of cellulase solution, keep shaking at 45°C for 5 hours, and boil for 5 minutes to inactivate the enzyme. Combine the filtrates for 3 times, concentrate until viscous, cool to room temperature, add 3 times the volume of ethanol and stir evenly, so that the alcohol content reaches 75%, let it stand overnight, collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com