Method for preparation of methyl ethyl carbonate with co-precipitation catalyst

A kind of technology of methyl ethyl carbonate and dimethyl carbonate, applied in the field of co-precipitation catalyst for preparing methyl ethyl carbonate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] Embodiment 1: the prepared Al with composite pore structure 2 o 3 -SiO 2 200 g of the carrier was placed in a muffle furnace and calcined at 500 °C for 4 hours to remove Al 2 o 3 -SiO 2 Adsorbed water; take 0.75 mol (238.5 g) Mg(NO 3 ) 2 ·6H 2 O, 0.20 mol (26.7 g) AlCl 3 , 0.02 mol (11.32 g) La 2 (SO 4 ) 3 Dissolve in 2000 mL deionized water to prepare a mixed solution of magnesium nitrate, aluminum chloride and lanthanum sulfate, and prepare 3 mol / L KOH and NaHCO 3 The mixed lye, the roasted Al 2 o 3 -SiO 2 Mix 200 g of the carrier with 2000 mL of deionized water, stir vigorously to make it evenly mixed with the water, and heat the solution containing the carrier to 70 °C in a water bath. Under vigorous stirring, in solution, drop the mixed solution of magnesium nitrate, aluminum chloride, lanthanum sulfate and lye simultaneously, control the rate of addition of magnesium nitrate, aluminum chloride and lanthanum sulfate mixed solution to be 3 ml / s, guaran...

Embodiment 2

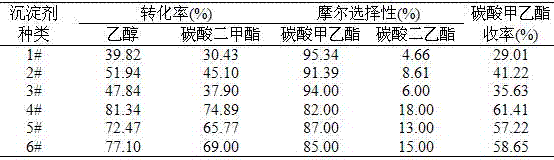

[0079] Embodiment 2: get 0.75 mol (238.5 g) Mg(NO 3 ) 2 ·6H 2 O, 0.20 mol (26.7 g) AlCl 3 , 0.02 mol (11.32g) La 2 (SO 4 ) 3 , replace the precipitant with NaOH (1#), KOH (2#), NH 3 ·H 2 O(3#), KOH and NaHCO 3 The mixed alkali (4#), NaOH and NH 3 ·H 2 Mixed base of O (5#), KOH and NH 3 ·H 2 The mixed base of O (6#), the catalyst carrier is Al 2 o 3 -SiO 2 , the precipitation temperature is 70 ℃, the precipitation pH is 11, and the aging time is 20 h. Using the similar preparation method in Example 1, the MgO loading is 15 wt%, and the Al 2 o 3 The load is 5%, La 2 o 3 The load is 3%, the supported catalyst with different precipitants is 15% MgO-5%Al 2 o 3 -3% La 2 o 3 / Al 2 o 3 -SiO 2 .

[0080] In the fixed-bed reactor, 15% MgO-5% Al prepared by precipitation with different precipitants were loaded respectively 2 o 3 -3%La 2 o 3 / Al 2 o 3 -SiO 2 Catalyst 50 g each, using a constant flow pump to pump dimethyl carbonate and ethanol into the react...

Embodiment 3

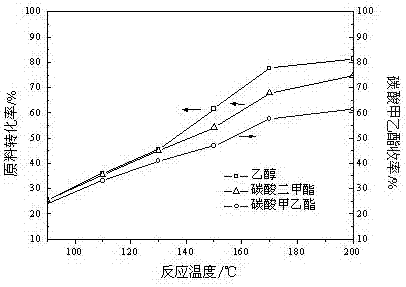

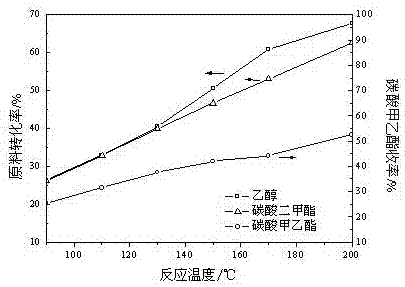

[0084] Embodiment 3: get 0.75 mol (238.5 g) Mg(NO 3 ) 2 ·6H 2 O, 0.20 mol (26.7 g) AlCl 3 , 0.02 mol (11.32g) La 2 (SO 4 ) 3 , the precipitation temperature is 25°C, 40°C, 50°C, 60°C, 70°C, 80°C, 90°C, and the catalyst carrier is Al 2 o 3 -SiO 2 , the precipitants are KOH and NaHCO 3 The mixed alkali, the precipitation pH is 11, and the aging time is 20 h. Using the similar preparation method in Example 1, it can be prepared that the MgO loading is 15 wt%, and the Al 2 o 3 The load is 5%, La 2 o 3 Supported catalysts with 3% loading and different precipitation temperatures 15% MgO-5%Al 2 o 3 -3% La 2 o 3 / Al 2 o 3 -SiO 2 . In the fixed-bed reactor, 15% MgO-5% Al prepared with different precipitation temperatures were loaded respectively 2 o 3 -3% La 2 o 3 / Al 2 o 3 -SiO 2 Catalyst 50 g each, using a constant flow pump to pump dimethyl carbonate and ethanol into the reactor according to the molar ratio of 1:1, the space velocity is 30 h -1 , normal pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com