Preparation and application of double long-chain alkyls-containing sulphonate type anionic surfactant

A surfactant and long-chain alkyl technology, applied in the field of colloid and interfacial chemistry, can solve the problem of low interfacial tension between crude oil and water, and achieve excellent lipophilicity, excellent chemical stability, surface activity, and small adsorption loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation of intermediate (I) containing didodecanyl

[0031]Add 0.25mol didodecanyl glyceryl ether and 0.35mol solid KOH into a 500mL three-necked flask, dissolve in 200mL n-hexane, and add 0.005mol TBAB as a catalyst. Then, 0.25mol epichlorohydrin was added dropwise at 30°C, and reacted at 50°C for 6 hours after the dropwise addition was completed. After the reaction was completed, the product was naturally cooled to room temperature, the inorganic salt was removed by vacuum filtration, and the solvent was removed by rotary evaporation to obtain the intermediate (I). The yield is about 85%.

Embodiment 2

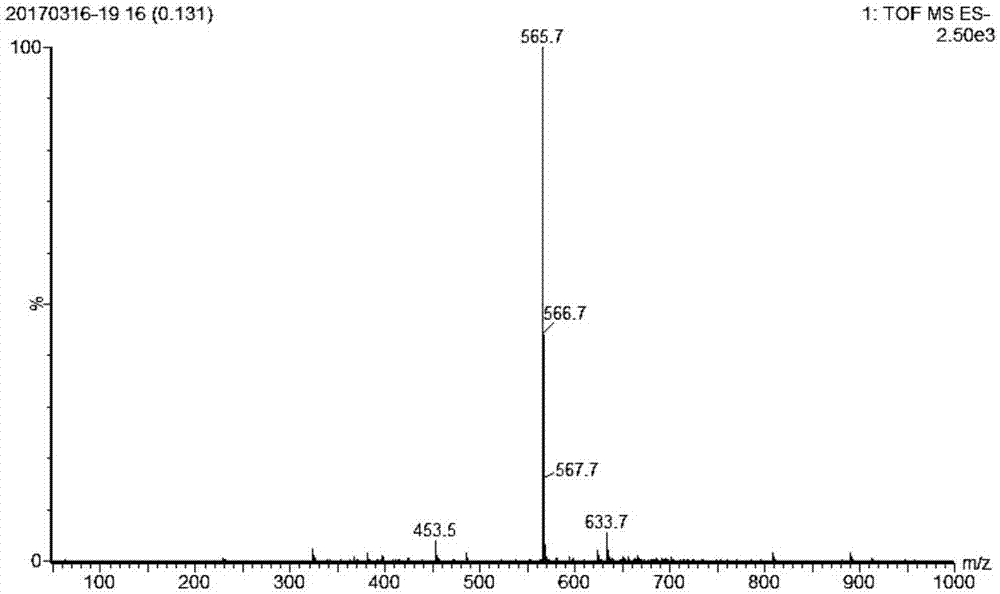

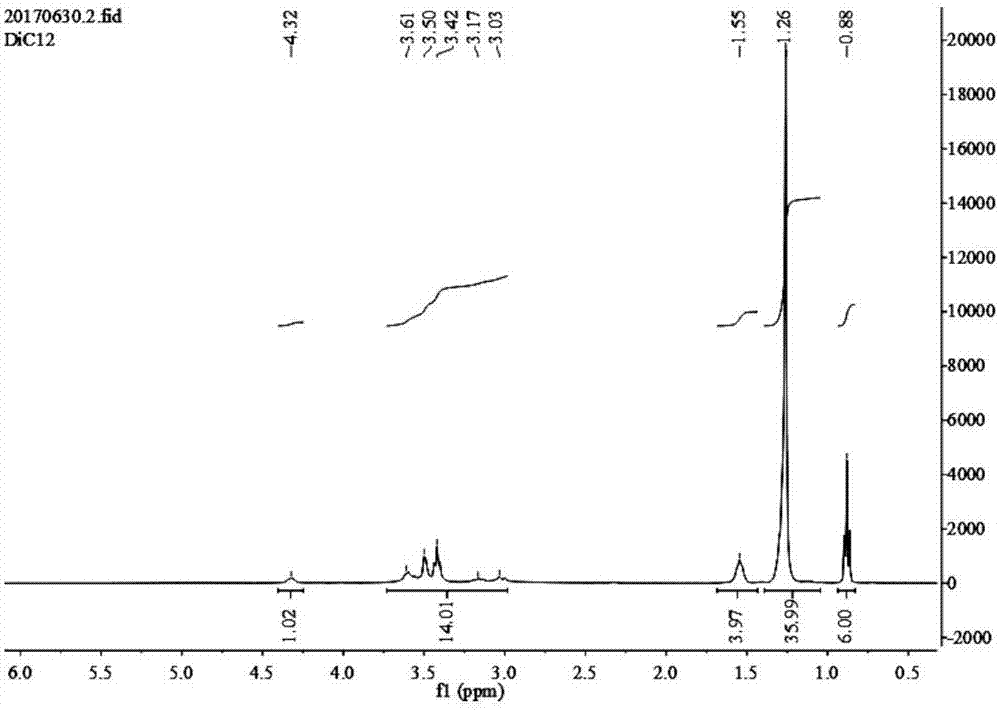

[0033] Preparation and Characterization of Dilauryl Ether Hydroxypropyl Sulfonate (II)

[0034] Add 0.1 mol of sodium bisulfite to a 250 mL three-necked flask, dissolve it in 100 mL of water, and then slowly add 0.1 mol of the intermediate (I) obtained above at 75° C. Raise the temperature to the reflux temperature (100±2° C.), and continue the reaction for 48 hours. After the reaction was finished, the moisture was evaporated, the reaction product was cooled to room temperature, dissolved in 400mL of ethyl acetate, filtered to remove salt, and the solvent was removed in vacuo to obtain the crude product of sodium didodecylglyceryl ether hydroxypropyl sulfonate. The rate is about 80%. Dissolve the crude product in 100 mL of isopropanol / water (volume ratio 1:1) mixed solvent, extract with petroleum ether several times, remove the unreacted intermediate (I), and remove the solvent by rotary evaporation to obtain the purified dioctol Sodium Alkyl Glyceryl Ether Hydroxypropyl Su...

Embodiment 3

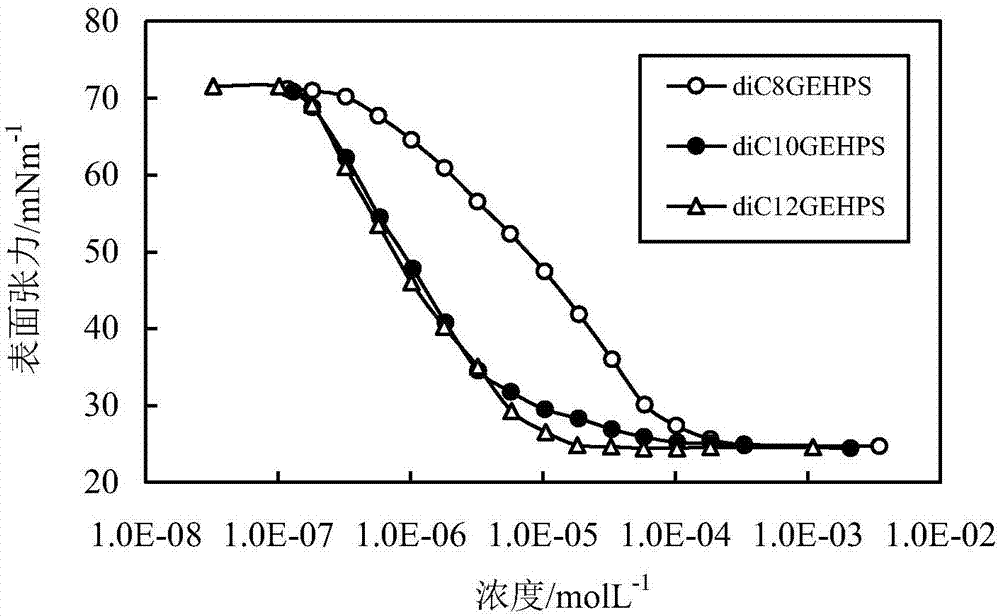

[0039] The synthesized sodium dialkyl glyceryl ether hydroxypropyl sulfonate was dissolved in pure water to prepare aqueous solutions of different concentrations, and the surface tension of the solution was measured by the suspension ring method at 25°C, and the relationship curve of the surface tension with the concentration was drawn, and the results were Such as image 3 shown. As can be seen from the figure, the critical micelle concentration (cmc) of dioctadecyl, didecyl and didodecyl glyceryl ether hydroxypropyl sulfonate sodium is 1.1×10 respectively. -4 mol / L,6.6×10 -6 mol / L, and 7.3×10 -6 mol / L, while the γ of the three sulfonates cmc Very low and basically the same, around 25mN / m. It shows that this series of surfactants has excellent surface activity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com