Device and method for preparing electronic ethylene carbonate by coupling crystallization with rectification

A technology coupled with ethylene carbonate and rectification, which is applied in the field of preparation of electronic grade reagents, can solve problems such as difficult balance between product purity and yield, unfavorable lithium-ion battery electrolyte, and poor lithium-ion battery, so as to ensure production operation Efficiency, high product purity, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

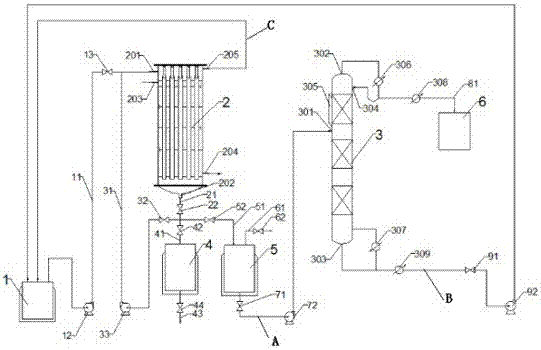

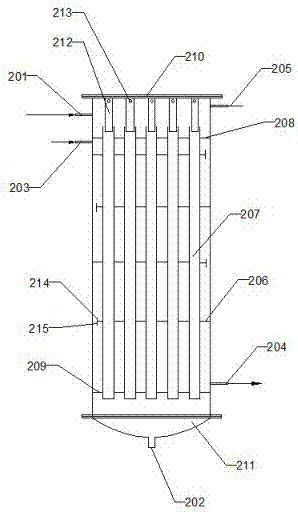

[0058] Such as figure 1 As shown, the present embodiment provides a device for preparing electronic-grade ethylene carbonate coupled with crystallization and rectification, including a raw material storage tank 1, a falling film crystallizer 2, a rectification tower 3, a first product tank 4, a transition tank 5 and Second product tank 6.

[0059] The connection relationship of each device is as follows:

[0060] The raw material storage tank 1 is connected to the feed port 201 of the falling film crystallizer 2 through the feed pipeline 11, and a discharge main pipe 21 is arranged at the discharge port 202 of the falling film crystallizer 2, and the end of the discharge main pipe 21 is connected with a circulation pipeline 31. The first product pipeline 41 and the transition pipeline 51, the circulation pipeline 31 is connected to the feed port 201 of the falling film crystallizer 2, the first product pipeline 41 is connected to the first product tank 4, and the transition p...

Embodiment 2

[0080] This embodiment provides a method for preparing electronic-grade ethylene carbonate coupled with crystallization and rectification, including a crystallization process and a rectification process, and the crystallization process includes the following steps:

[0081] Crystallization: The ethylene carbonate material to be purified is transported from the raw material storage tank 1 to the falling film crystallizer 2, the material enters the falling film crystallizer 2 and flows in the falling film in the crystallization tube, and the temperature of the cooling medium is adjusted so that the material is Crystallize in the crystallization tube, stop feeding when the crystal layer reaches a certain thickness;

[0082] Sweating: Then gradually increase the temperature of the cooling medium to make the crystal layer sweat, and discharge the sweating residue into the transition tank 5;

[0083] Crystallization and melting: after sweating, further increase the temperature of th...

Embodiment 3

[0094] Different from Example 2 are the operating conditions of the crystallization process and the operating conditions of the rectifying process, and all the other are the same as Example 2.

[0095] In the present embodiment, the operating conditions of the crystallization process are:

[0096] The feed flow rate of ethylene carbonate is 200L / h, and the feed temperature is 42°C;

[0097] During the falling film crystallization process, the cooling step length is 1.5°C / h, the crystallization time is 6h, and the end point temperature of cooling crystallization is 33°C, followed by constant temperature for 2h;

[0098] The temperature rise step in the sweating process is 3°C / h, the sweating time is 3h, and the sweating end point temperature is 37°C;

[0099] The temperature during the melting of the crystals was 45°C.

[0100] The operating conditions of the rectification process are:

[0101] The vacuum distillation operation is adopted, the pressure inside the tower is 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com