Corrosion-resistant graphene industrial coating as well as preparation method and application thereof

A graphene, anti-corrosion technology, applied in anti-corrosion coatings, coatings and other directions, can solve problems such as the inability to effectively slow down the contact between oxygen and metal, the separation of coating and metal, and the aggravation of metal deterioration, achieve high hardness and slow down metal corrosion. , the effect of saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

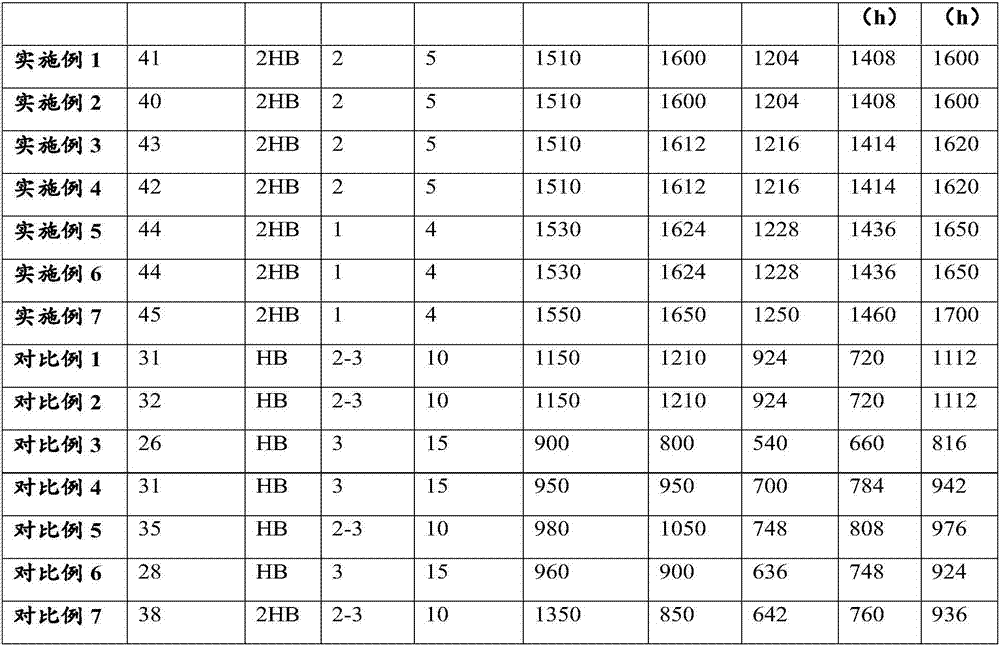

Examples

preparation example Construction

[0032] In a preferred embodiment of the present invention, the preparation method of graphene-zinc nanocomposite includes the following steps:

[0033] (a) Disperse zinc compound and graphene oxide in an alkaline solution for reaction to generate graphene oxide-zinc hydroxide composite;

[0034] (b) The graphene oxide-zinc hydroxide composite is subjected to a reduction reaction to obtain the graphene-zinc nanocomposite;

[0035] Wherein, the zinc compound is selected from at least one of zinc acetate, zinc propionate, zinc butyrate, zinc sulfate, zinc chloride and zinc nitrate.

[0036] In a preferred embodiment of the present invention, zinc acetate and graphene oxide are added to the alkaline solution in a mass ratio of (5-6):4 to react to generate graphene oxide-zinc hydroxide composite, which is washed and removed After impurities, sodium borohydride is added to reduce the graphene oxide-zinc hydroxide composite to obtain a graphene-zinc nanocomposite.

[0037] In a preferred embo...

Embodiment 1

[0054] This embodiment provides an anti-corrosion graphene industrial coating prepared from the following raw materials in parts by mass: 450 parts of styrene-acrylic emulsion, 80 parts of graphene-zinc nanocomposite, and 200 parts of wollastonite. 205 parts of ionized water, 5 parts of ethylene glycol, 1 part of AMP95, 10 parts of sodium lauryl sulfate, 1 part of glycerin, 1 part of T08, 1 part of octanol, 3 parts of ammonia, 40 parts of propylene glycol, 1 part of butanol, 5 parts of anti-flash rust agent, 3 parts of RM2020, 4 parts of RM 8W; among them, the graphene-zinc nanocomposite is prepared according to the following steps: 2.75g zinc acetate dihydrate, 200mg graphene oxide and 1g NaOH are dispersed in 25mL concentration In a 25% NH3·H2O solution, after reacting for 1 hour, adjust the pH to 11 with 0.1 mol / L NaOH, and continue the reaction for 2 hours to form a graphene oxide-zinc hydroxide complex. After washing to remove impurities, 1 g of sodium borohydride was adde...

Embodiment 2

[0056] This embodiment provides a corrosion-resistant graphene industrial coating. The difference between this embodiment and Embodiment 1 is that the styrene-acrylic emulsion is 550 parts, the graphene-zinc nanocomposite is 20 parts, and the wollastonite is 80 parts. Parts, 125 parts of iron red and 150 parts of deionized water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexibility | aaaaa | aaaaa |

| Salt spray resistance | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com