Praseodymium-doped laminated perovskite type red long-lasting phosphor material as well as preparation method and application thereof

A long-lasting luminescent, perovskite-type technology, applied in luminescent materials, chemical instruments and methods, etc., can solve problems such as unfavorable application promotion, easy deliquescent, harsh synthesis conditions, etc., achieve good physical and chemical stability, excellent red color Afterglow performance, the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for preparing a praseodymium-doped layered perovskite-type red long-lasting luminescent material, comprising the following steps:

[0033]1) The analytically pure powder raw materials CaO, TiO 2 、Pr 6 o 11 、Dy 2 o 3 、K 2 CO 3 Press Ca 2+ : Ti 4+ : Pr 3+ : Dy 3+ :K + = 3.975: 3: 0.005: 0.01: 0.01 molar ratio weighing and mixing, and placed in an agate mortar;

[0034] 2) Add 5ml of ethanol to the mixed raw materials in the agate mortar, and grind for 30 minutes;

[0035] 3) Put the ground mixed raw material in a square crucible, put it into a box furnace, heat it to 1300°C, and keep it warm for 2 hours to make it undergo a solid phase reaction;

[0036] 4) After the box-type furnace is cooled, grind the mixed raw materials and pass through a mesh sieve.

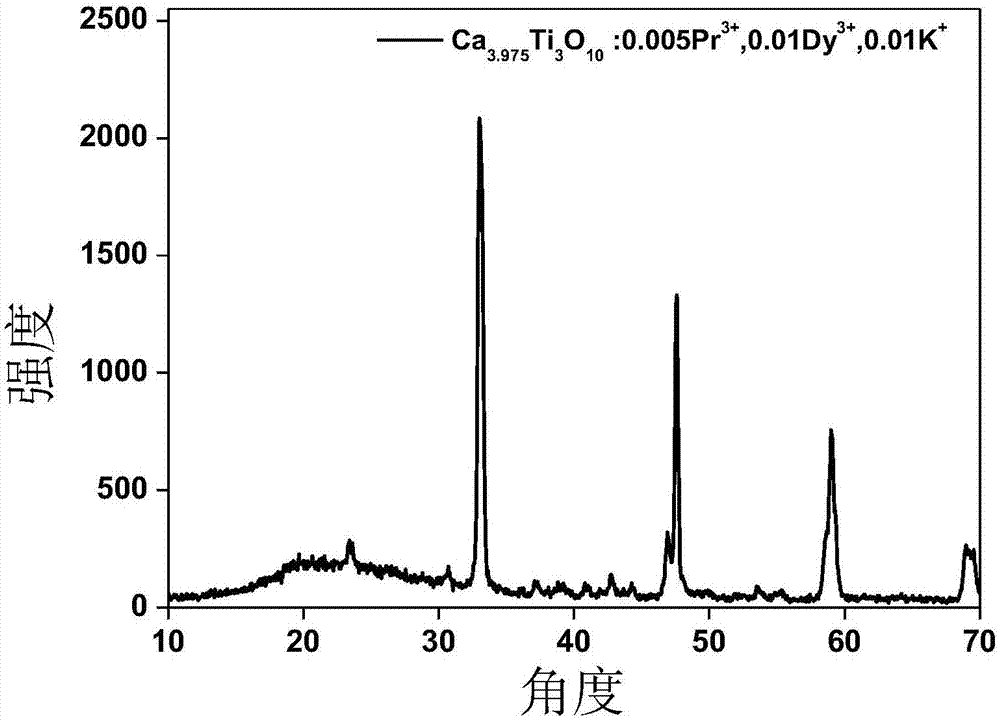

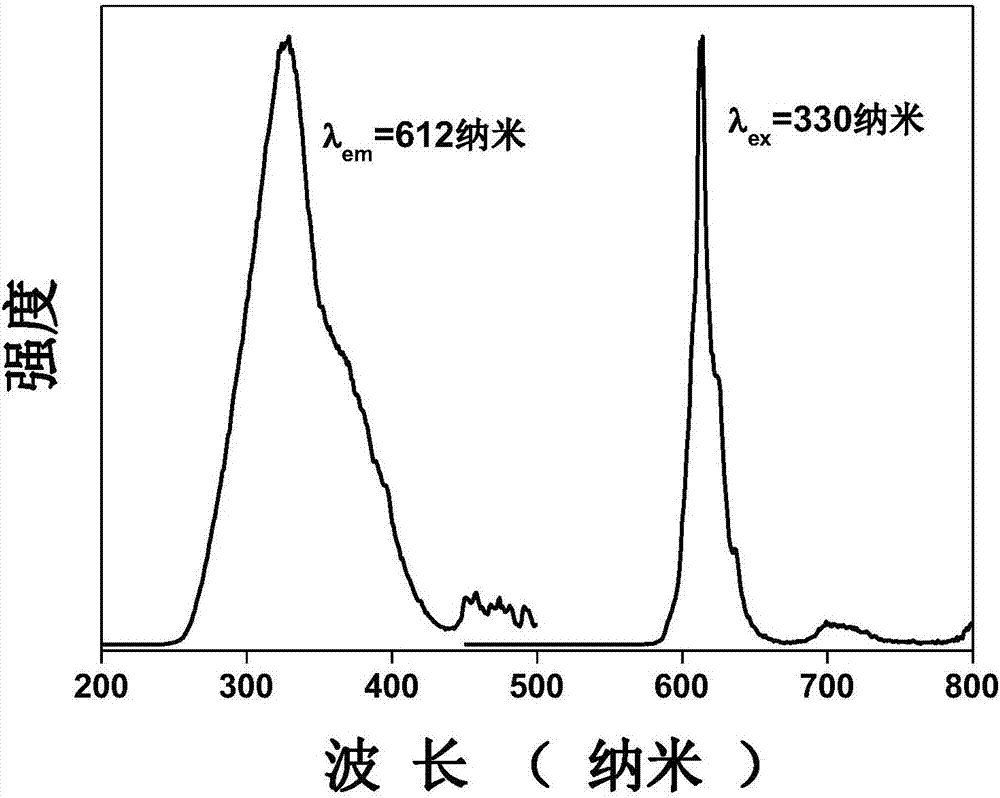

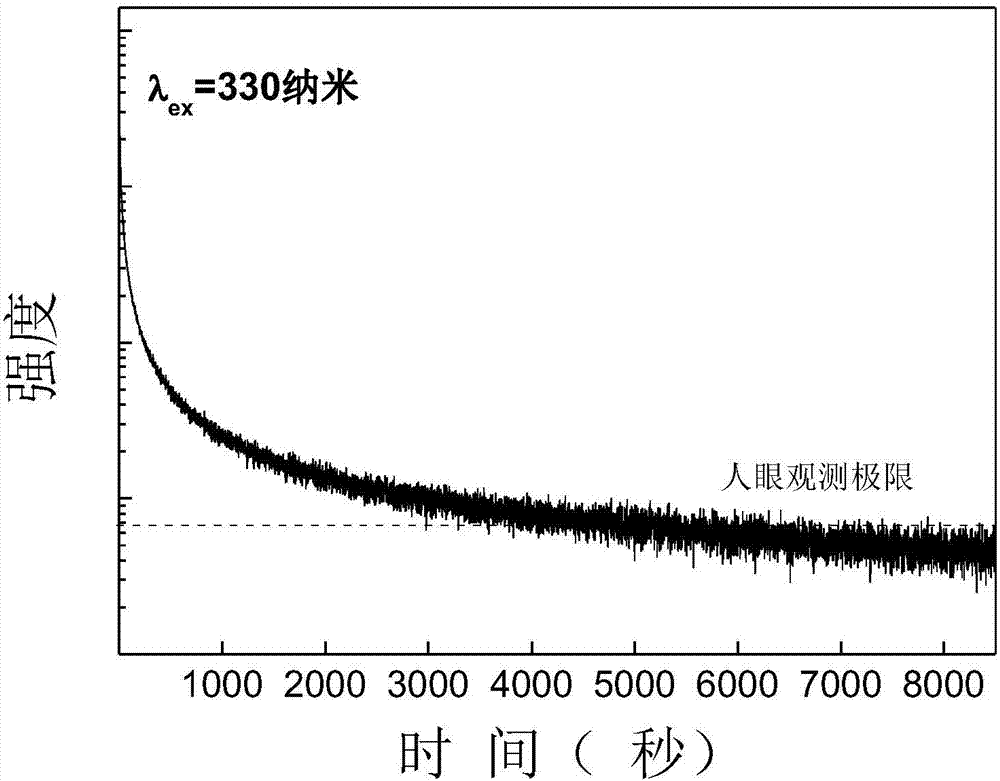

[0037] Such as figure 1 As shown, according to the X-ray analysis results, the obtained luminescent material is pure phase Ca 4 Ti 3 o 10 . Such as figure 2 As shown, the excitation and emis...

Embodiment 2

[0039] A method for preparing a praseodymium-doped layered perovskite-type red long-lasting luminescent material, comprising the following steps:

[0040] 1) The analytically pure powder raw materials SrO, TiO 2 、Pr 6 o 11 、Tm 2 o 3 , ZnO by Sr 2+ : Ti 4+ : Pr 3+ : Tm 3+ : Zn 2+ = 3.97: 3: 0.005: 0.01: 0.015 molar ratio weighing and mixing, and placed in an agate mortar;

[0041] 2) Add 6ml of ethanol to the mixed raw materials in the agate mortar, and grind for 60 minutes;

[0042] 3) Put the ground mixed raw material in a square crucible, put it into a box furnace, heat it to 1400°C, and keep it warm for 4 hours to make it undergo a solid phase reaction;

[0043] 4) After the box-type furnace is cooled, grind the mixed raw materials and pass through a mesh sieve.

[0044] According to the X-ray analysis results, the obtained luminescent material is pure phase Sr 4 Ti 3 o 10 . Under excitation at 330 nm, the sample showed bright red emission; after the excitati...

Embodiment 3

[0046] A method for preparing a praseodymium-doped layered perovskite-type red long-lasting luminescent material, comprising the following steps:

[0047] 1) The analytically pure powder raw materials MgO, TiO 2 、Pr 6 o 11 , Yb 2 o 3 , Ga 2 o 3 by Mg 2+ : Ti 4+ : Pr 3+ : Yb 3+ : Ga 3+ = 3.965: 3: 0.005: 0.01: 0.02 Weigh and mix in molar ratio, and place in agate mortar;

[0048] 2) Add 9ml of ethanol to the mixed raw materials in the agate mortar, and grind for 120 minutes;

[0049] 3) Put the ground mixed raw material in a square crucible, put it into a box furnace, heat it to 1500°C, and keep it warm for 6 hours to make it undergo a solid phase reaction;

[0050] 4) After the box-type furnace is cooled, grind the mixed raw materials and pass through a mesh sieve.

[0051] According to the X-ray analysis results, the obtained luminescent material is pure phase Mg 4 Ti 3 o 10 . Under excitation at 330 nm, the sample showed bright red emission; after the excita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com