A kind of fragrance-carrying electrospun membrane and preparation method thereof

An electrospun membrane and fragrance-carrying technology, applied in textiles and papermaking, cellulose/protein conjugated artificial filaments, filament/thread forming, etc., can solve the problems of easy detachment of microcapsules, short fragrance retention time and high cost , to achieve the effect of improving the fragrance loading efficiency, improving the barrier effect, and improving the loading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Weigh a certain amount of anhydrous sodium carbonate (if the concentration of sodium carbonate is 0, do not add), add 1L of deionized water, stir to dissolve, heat to boiling, add weighed 10g silkworm cocoons (produced in Tongxiang, Zhejiang), and boil for 30min. After cooling, filter with suction and wash the silk with a large amount of water; repeat the above operation twice, put the silkworm cocoons after the third suction filter into a vacuum oven to dry, weigh and calculate the reduction rate.

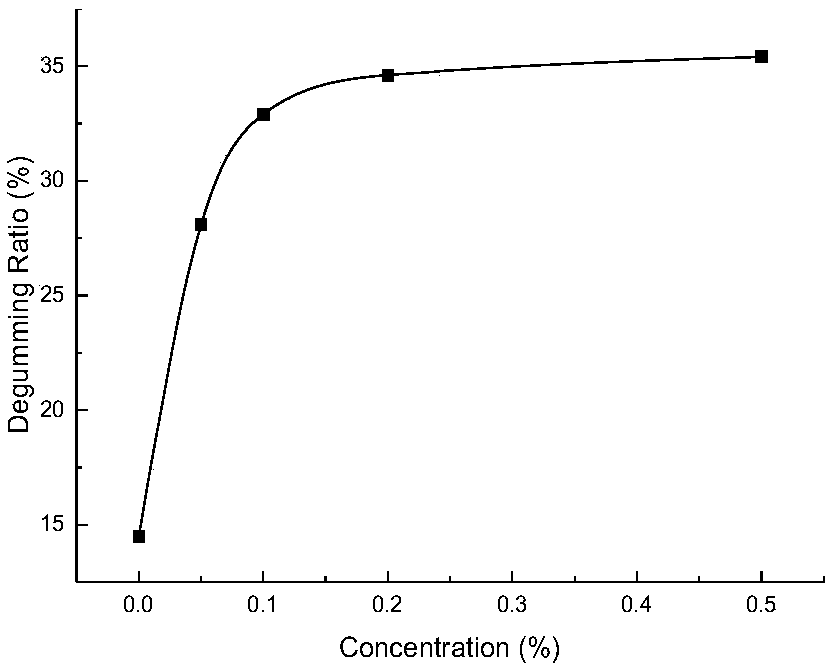

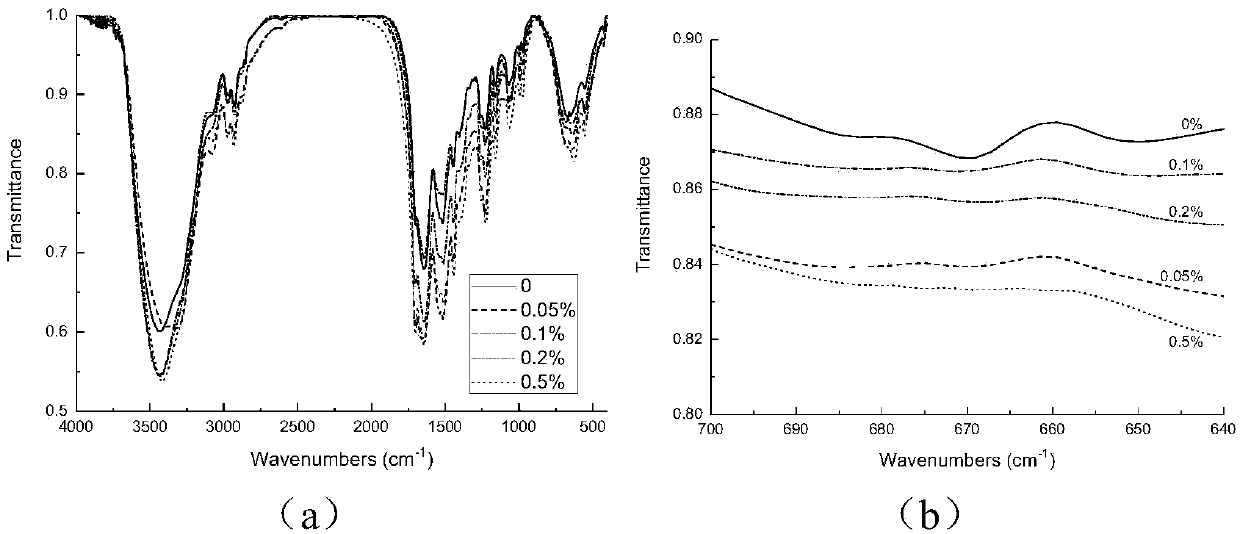

[0034] Respectively with 0% (ie pure water), 0.05%, 0.1%, 0.2% and 0.5% Na 2 CO 3 The solution degummed silkworm cocoons, in which 0% was degummed for 2 hours each time, repeated three times, and other concentrations were degummed for 1 hour. See figure 1 , the infrared spectrum of the product see figure 2 a, Partial zoom-in of the infrared spectrum is shown in figure 2 b.

[0035] Depend on figure 1 The results show that the addition of sodium carbonate can signifi...

Embodiment 2

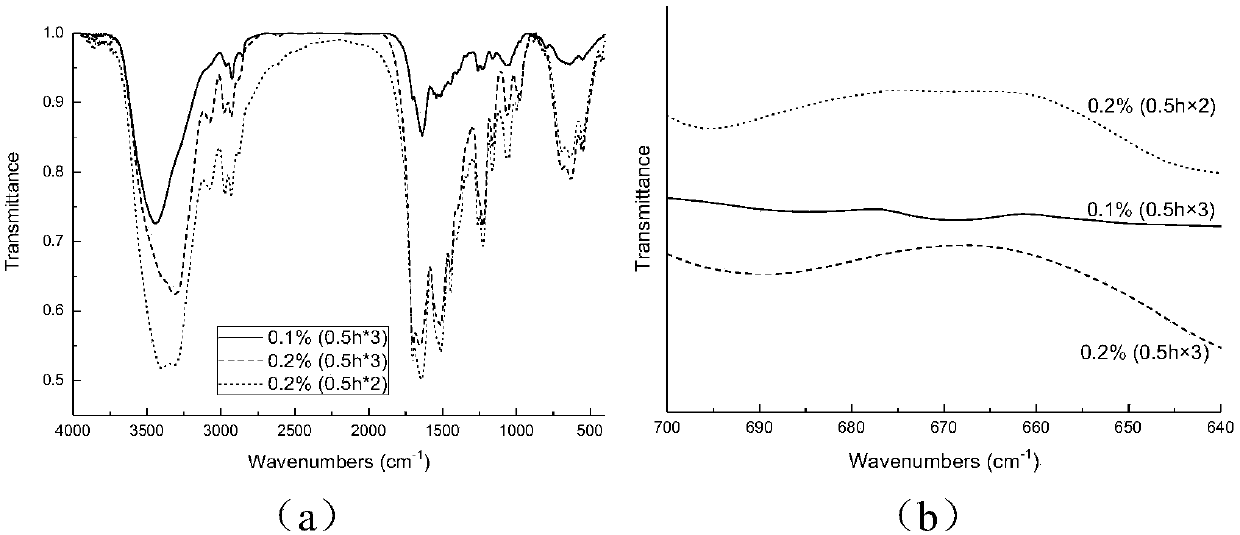

[0038] The operating conditions are substantially the same as in Example 1, except that the concentration and the number of times of degumming are changed. The specific conditions are: a) 0.1% Na 2 CO 3 solution, degummed three times, each 0.5h; b) 0.2% Na 2 CO 3 solution, degummed three times, each 0.5h; c) 0.2% Na 2 CO 3 Solution, degummed twice, each 0.5h, measure its infrared spectrum, the result sees image 3 a and image 3 b, where image 3 b for image 3 a at 700-640cm -1 The partially enlarged spectrum at .

[0039] Depend on image 3 (a) and image 3 The results of (b) show that the measured infrared spectrum shows that with 0.1% Na 2 CO 3 The silk obtained by solution degumming is at 669cm -1 There is still the characteristic absorption peak of the amide V band at the place, indicating that there is still sericin residue; 0.2% Na 2 CO 3 The silk obtained by degumming the solution for three times is at 669cm -1 There is no absorption peak, and the ser...

Embodiment 3

[0041] The refined silk fibroin completely degummed in Example 2 was dissolved, dialyzed, and freeze-dried to prepare regenerated silk fibroin. Weigh 5g of dry refined silk fibroin, add 50mL 9.3mol / L LiBr aqueous solution, dissolve at 60°C for 4h, cool to room temperature and filter with sand core. The filtrate was transferred to a regenerated cellulose dialysis bag (MWCO=1000), placed in 1000 mL deionized water for dialysis for 3 days, and the water was changed every 3 h. After the dialysis is completed, suction filter with a sand core, transfer the filtrate to a polystyrene Petri dish (surface treatment), and freeze-dry. Store in a desiccator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com