Modified starch-based toughened thermoplastic composite material and preparation method thereof

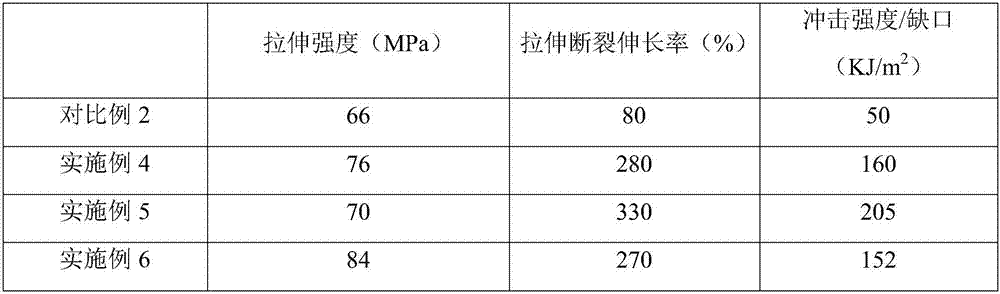

A composite material and thermoplastic technology, which is applied in the field of modified starch-based toughening thermoplastic composite materials and its preparation, can solve problems such as insufficient environmental protection of the toughening agent, and achieve the effects of low cost, easy industrialized production and high toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

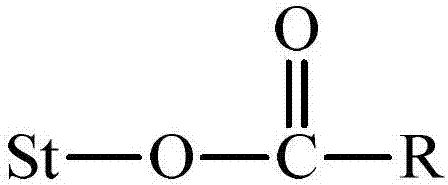

[0043] Mix 100 parts of corn starch (manufactured by Changchun Dacheng Corn Development Co., Ltd.) and 50 parts of dimethylformamide (manufactured by Sinopharm Chemical Reagent Co., Ltd.) at 60°C, stir and mix thoroughly for 30 minutes, and then add pyridine dropwise while stirring (produced by Sinopharm Chemical Reagent Co., Ltd.) 10 parts, after the dropwise addition is completed, continue to stir for 1 hour.

[0044] Then add 1 part of acryloyl chloride (produced by Shanghai Jingchun Biochemical Technology Co., Ltd.) dropwise and continue to stir for 30 minutes, add absolute ethanol (produced by Sinopharm Chemical Reagent Co., Ltd.) to wash, suction filter and dry.

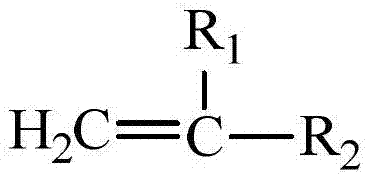

[0045] Disperse 20 parts of the prepared modified starch, 0.1 part of potassium persulfate (produced by Sinopharm Chemical Reagent Co., Ltd.) in 50 parts of water, ultrasonically disperse to obtain an emulsion, add 10 parts of butyl acrylate (produced by Sinopharm Chemical Reagent Co., Ltd. ), stirred and react...

Embodiment 2

[0048] Mix 100 parts of corn starch (manufactured by Changchun Dacheng Corn Development Co., Ltd.) and 150 parts of dimethylformamide (manufactured by Sinopharm Chemical Reagent Co., Ltd.) at 60°C, stir and mix thoroughly for 30 minutes, and then add pyridine dropwise while stirring (produced by Sinopharm Chemical Reagent Co., Ltd.) 30 parts, after the dropwise addition was completed, continue to stir for 1 hour.

[0049]Then dropwise add 6 parts of acryloyl chloride (produced by Shanghai Crystal Pure Biochemical Technology Co., Ltd.), 14 parts of stearyl chloride (produced by Shanghai Crystal Pure Biochemical Technology Co., Ltd.) and continue stirring for 30 minutes. Group Chemical Reagent Co., Ltd.) washed, filtered and dried.

[0050] Disperse 20 parts of the prepared modified starch, 0.2 parts of potassium persulfate (produced by Sinopharm Chemical Reagent Co., Ltd.) in 100 parts of water, ultrasonically disperse to obtain an emulsion, add 30 parts of ethyl acrylate (prod...

Embodiment 3

[0053] Mix 100 parts of corn starch (manufactured by Changchun Dacheng Corn Development Co., Ltd.) and 200 parts of dimethylformamide (manufactured by Sinopharm Chemical Reagent Co., Ltd.) at 60°C, stir and mix thoroughly for 30 minutes, and then add pyridine dropwise while stirring (produced by Sinopharm Chemical Reagent Co., Ltd.) 50 parts, after the dropwise addition was completed, continue to stir for 1 hour.

[0054] Then dropwise add 25 parts of acryloyl chloride (produced by Shanghai Crystal Pure Biochemical Technology Co., Ltd.), 25 parts of stearyl chloride (produced by Shanghai Crystal Pure Biochemical Technology Co., Ltd.) and continue to stir for 30 minutes. Group Chemical Reagent Co., Ltd.) washed, filtered and dried.

[0055] 20 parts of the prepared modified starch, 0.5 parts of potassium persulfate (produced by Sinopharm Chemical Reagent Co., Ltd.) were dispersed in 200 parts of water, ultrasonically dispersed to obtain an emulsion, and 40 parts of ethyl acryla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com