Polycaprolactone/collagen/quaternary ammonium salt electrospun composite fiber membrane and method for preparing same

A composite fiber membrane, polycaprolactone technology, applied in electrospinning, fiber processing, pharmaceutical formulations, etc., can solve problems such as poor mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific embodiments of the present invention are given below to further illustrate the structure of the present invention, but it is not considered that the present invention is limited to the following embodiments.

[0036] The preparation method of polycaprolactone / collagen / quaternary ammonium salt electrospinning composite fiber membrane of the present invention is as follows:

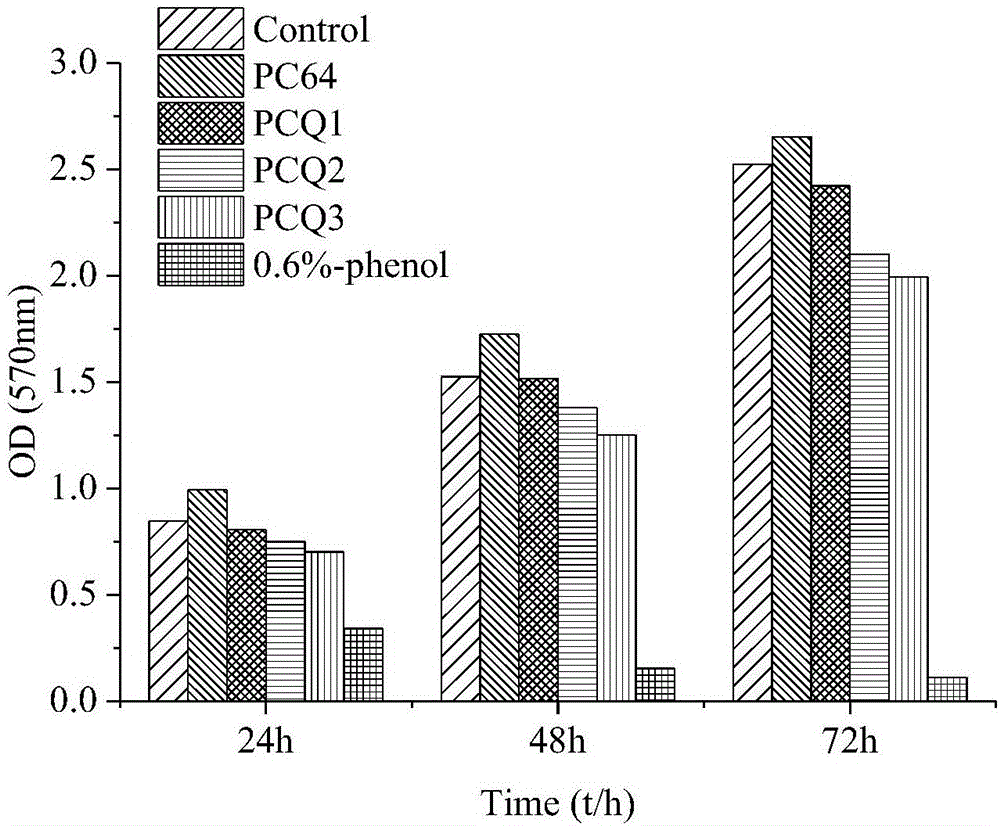

[0037] (1) Determination of the optimal ratio of polycaprolactone / collagen

[0038] Weigh a certain amount of polycaprolactone particles, dissolve in hexafluoroisopropanol, acetic acid, dichloromethane or trifluoroacetic acid, stir evenly at room temperature with magnetic force, after completely dissolving, weigh collagen and add in a certain mass ratio In the polycaprolactone solution, continue magnetic stirring to dissolve, and prepare a spinning solution with a mass fraction of 6%, and a PCL / COL mass ratio of 80:20, 60:40, 50:50, 40:60, and 20:80, The spinning parameters were fixed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com