Method for manufacturing metal bonding agent and super-hard abrasive structured arrangement end face grinding wheel through laser cladding process

A metal bond, super-hard abrasive technology, applied in abrasives, grinding devices, metal processing equipment, etc., can solve the problem that the laser sintering powder layer cannot be closely combined with the substrate, the thickness uniformity of the powder is difficult to ensure, and it is not conducive to super-hard Abrasive grinding tool preparation and other issues, to achieve the effect of shortening processing time, reducing processing cost, and making flexible and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

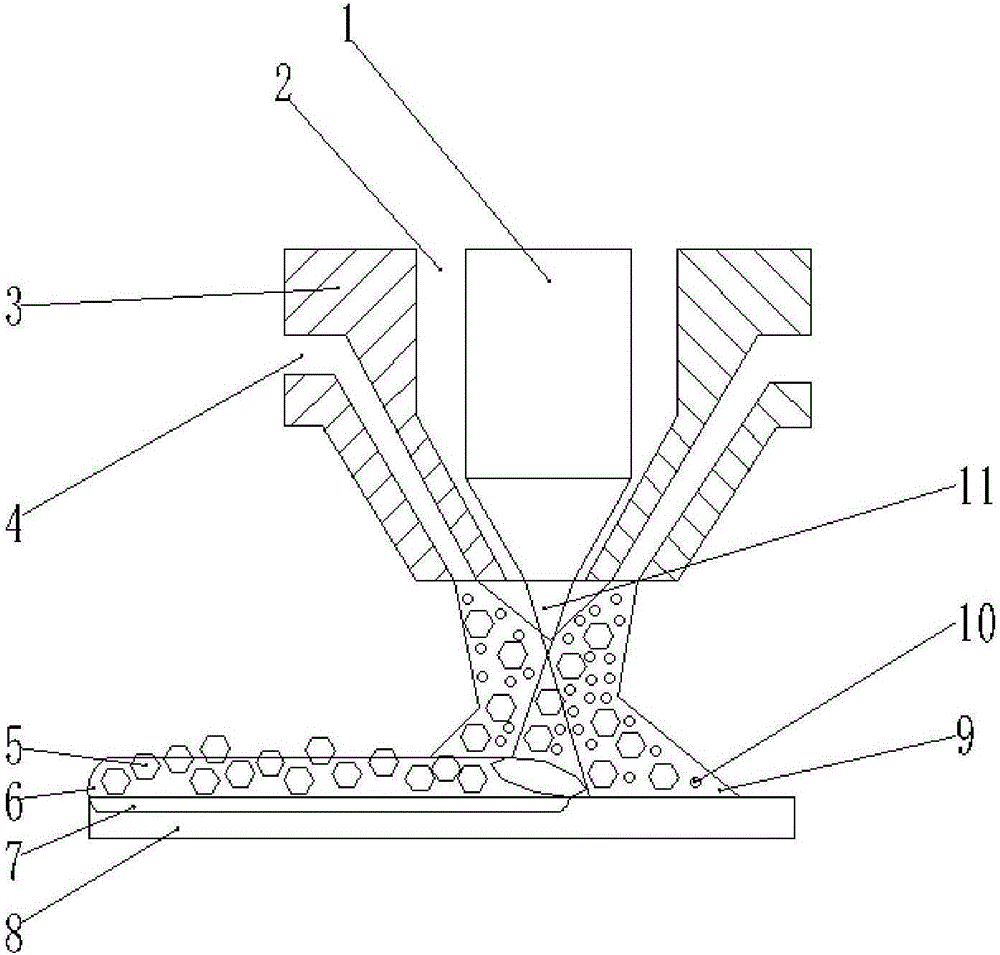

[0047] A method for producing a metal bond superabrasive structured end face grinding wheel with a laser cladding process, comprising the following steps:

[0048] S1. Weigh the atomized spherical 400-mesh copper-based alloy powder Cu-10Sn-12Ti and non-coated CBN according to the mass fraction ratio of 40:3, and mix them in a mixing bottle to obtain an unmixed uniform metal powder super Hard abrasive mixed powder;

[0049] S2. Add corundum balls of a certain quality and size to the mixing bottle. The mass ratio of the total mass of the corundum balls to the unmixed metal powder superhard abrasive mixed powder obtained in step S1 is 6:1, and the size of the corundum balls is 1. After that, seal the mixing bottle and put it into a ball mill for ball milling to obtain a uniformly mixed metal powder superabrasive mixed powder. The ball milling time is 5 hours;

[0050] S3. Pour the uniformly mixed metal powder superabrasive mixed powder together with corundum balls on the sieving...

Embodiment 2

[0056] A method for producing a metal bond superabrasive structured end face grinding wheel with a laser cladding process, comprising the following steps:

[0057] S1. Weigh the atomized spherical 400-mesh elemental copper powder, elemental nickel powder, elemental tin powder, and elemental titanium powder according to the mass fraction ratio of 7:6:5:2, and pour them into the mixing bottle. The elemental copper Powder, the purity of the elemental nickel powder, the elemental tin powder and the elemental titanium powder is 99.9%, and the titanium-plated CBN is based on the elemental copper powder, the elemental nickel powder, the elemental tin powder and the The total mass of the elemental titanium powder and the CBN mass ratio of the plated titanium is 40:3 for weighing, and together with the elemental copper powder, the elemental nickel powder, the elemental tin powder and the elemental titanium powder Mix in the mixing bottle to obtain metal powder superabrasive mixed powde...

Embodiment 3

[0065] A method for producing a metal bond superabrasive structured end face grinding wheel with a laser cladding process, comprising the following steps:

[0066] S1. Weigh atomized spherical 300-mesh silver-based alloy powder 70.5Ag-27.5Cu-2Ti and non-coated diamond according to the mass fraction ratio of 20:1, and mix them in a mixing bottle to obtain unmixed metal Powder superabrasive mixed powder;

[0067] S2. Add corundum balls of a certain quality and size to the mixing bottle. The mass ratio of the total mass of the corundum balls to the unmixed metal powder superabrasive mixed powder obtained in step S1 is 6:1, and the size of the corundum balls is 3mm. , after that, the mixing bottle is sealed, put into a ball mill and carry out ball milling to obtain a uniformly mixed metal powder superabrasive mixed powder, and the time of ball milling is 2 hours;

[0068] S3. Pour the uniformly mixed metal powder superabrasive mixed powder together with corundum balls on the siev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com